Reducing Risks from Contacts by using a Fast Trip during Hot Line Tags

One way to reduce risks of SIFs is to use a hot line tag. Utilities typically block reclosing during a hot line tag. Utilities can further reduce risks of SIFs by enabling a fast trip curve on an upstream device. For more information on using hot line tags, see EPRI 3002030783 (2024) 1.

Contact Scenarios

Contact scenarios may be the top reason to consider the fastest possible tripping under a hot line tag. Contact to primary voltage is the leading cause of serious injuries and fatalities (SIFs) to line workers on distribution systems. One analysis showed that contact was more than seven times more frequent than arc flash as the main cause of serious accidents based on OSHA reports (EPRI 1018694, 2009 2). If the contact causes a low-impedance fault path, fast tripping can greatly reduce injuries and increase the probability of surviving the contact.

When a line worker makes a bridging contact to the primary (between phases or phase to ground), current can flow along two paths:

-

Internal–The skin punctures, and current travels through organs. Entry and exit wounds are present. Fault impedance is high (500 to 1000 Ω), and currents are low (~10 A). Clearing times can be indefinite. Internal current flow can damage organs or cause atrial fibrillation.

-

External–A path flashes over along the skin, and current travels just above the skin. This has been called a tracking arc. See Jooma (2019) 3 and this section (member link). This fault is low impedance and high current (kA). Clearing time is a function of the speed of upstream protective devices.

With a tracking arc, fast protection speeds can reduce injuries. The tracking arc is an extreme arc flash. The arc is near the skin and below the workers clothing. Tracking arcs tend to happen with sweaty skin. Faster protection reduces the energy in the arc. Arc energy is approximately linear with time, so cutting the duration in half will reduce the arc energy in half.

Some have said that if a primary contact happens, it doesn’t matter what protection is on the line. Field experience and tests contradicts that. Many primary contacts are survivable, and fast protection can help reduce the severity of injuries from tracking arcs.

To compare protection speeds with a contact scenario, a test was setup using a manikin at the EPRI Lenox Laboratory. A tracking fault was initiated by placing a thin fusing wire under the manikin’s clothing. This test was repeated for two different protection speeds:

- 39 cycles, 2.4 kA, 468 kJ of arc energy – Figure 1

- 3 cycles, 2.7 kA, 18 kJ of arc energy – Figure 2

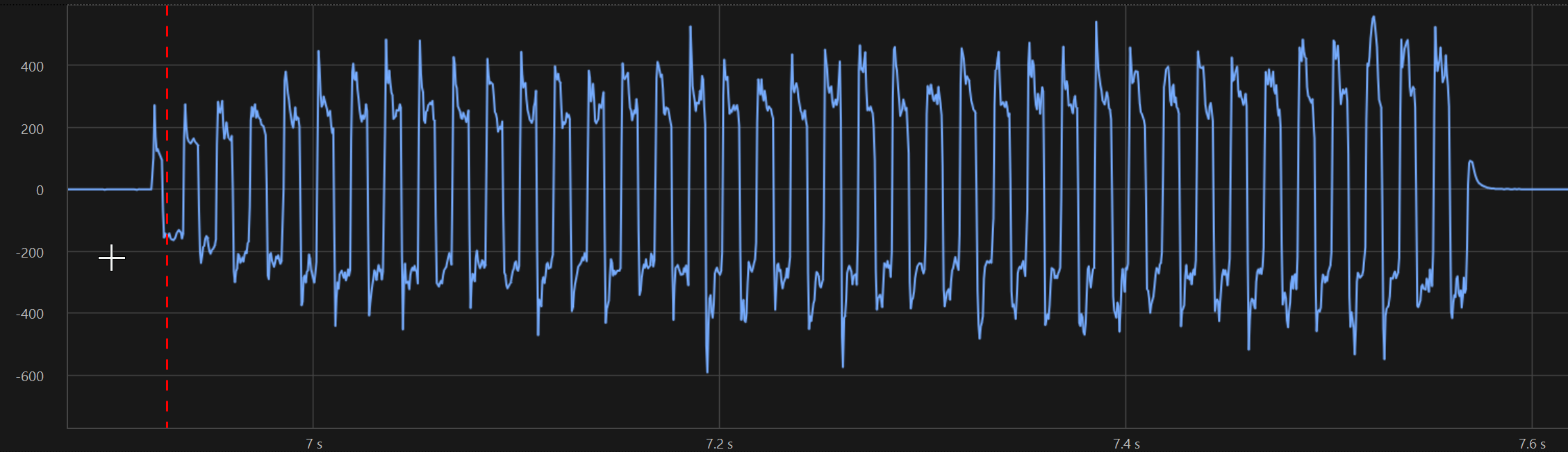

The 3-cycle test is a clearing time that could be possible for a fast trip on a vacuum recloser. The 39-cycle test could be the time for a delayed trip. The durations differ by a factor of 13. The arc energies differ by a factor of 26. Arc energies are higher by a larger factor because the arc voltage was higher during the longer test. Arcs tend to grow with time duration, and longer arcs have more voltage drop. See Figure 3 for the arc voltage from test 1 that shows the arc voltage increasing after the first few cycles.

The damage to the shirt in the 3-cycle test (Figure 4) was enough to suggest that the worker would have a burn, but not a life-threatening injury. Damage was much less than the damage from the 39-cycle test. The damage in the 39-cycle test would likely be life threatening. Faster tripping and lower arc energies also reduce risks of undergarments igniting.

Accidents involving contact are a challenge. Utilities have several direct and indirect controls to try to reduce risks of contact, including

- Rubber gloves and sleeves

- Insulated booms in bucket trucks

- Rubber coverup

- Hotsticks

- Practices during work (like removing jumpers that can’t be covered or proper bucket positioning)

- Training

Despite all of these controls, contact scenarios still happen. Faster protection during hot line tags could provide another level of risk reduction.

Impact of Protection Speeds on Other Work Scenarios

Contact to the primary are not the only hazards dependent on the duration of faults. Other hazards include:

- Arc flash

- Ground-level step and touch voltages

- Step and touch voltages in underground work

- Internal failures in equipment

- Line burndowns with coverup

Faster tripping can reduce risks for all of these hazards. For more information on how these hazards relate to tripping speed, see EPRI 3002030783 (2024) 1.

At a recent SIFs workshop, two utilities reported on workers getting into energized cables. In both cases, injuries from the arc flash were much less than they could have been because the faults cleared quickly on an instantaneous trip. See here for a case where a worker cut into live cable and here for a case where a worker opened a live end cap (member links).

References

EPRI 1018694, Distribution Arc Flash: Industry Practice, Electric Power Research Institute, Palo Alto, CA, 2009.

EPRI 3002030783, Hot Line Tags: Developing a Comprehensive Strategy, Electric Power Research Institute, Palo Alto, CA, 2024.

Jooma, Z., Hoagland, H., and Hines, R. W., “How Expert Advice in a Tracking-Arc Incident Investigation Saved Money: Preventing Unnecessary Spending on New Personal Protective Equipment,” IEEE Industry Applications Magazine, vol. 25, no. 3, pp. 60-64, May-June 2019.

-

EPRI 3002030783, Hot Line Tags: Developing a Comprehensive Strategy, Electric Power Research Institute, Palo Alto, CA, 2024. ↩︎ ↩︎

-

EPRI 1018694, Distribution Arc Flash: Industry Practice, Electric Power Research Institute, Palo Alto, CA, 2009. ↩︎

-

Jooma, Z., Hoagland, H., and Hines, R. W., “How Expert Advice in a Tracking-Arc Incident Investigation Saved Money: Preventing Unnecessary Spending on New Personal Protective Equipment,” IEEE Industry Applications Magazine, vol. 25, no. 3, pp. 60-64, May-June 2019. ↩︎