Non-Expulsion Fuse Designs

Risk Reduction Category

Technology Description

An expulsion Fuse is defined as a vented fuse in which the expulsion effect of gasses produced by the arc and lining of the fuse holder, either alone or aided by a spring, extinguishes the arc [1].

Non-explusion fuse designs on the other hand, including current-limiting fuses, have means to contain the gasses and molten particles. For example, current-limiting fuses have four parts common to all designs: tube, end ferrules, element, and arc quenching filler. The tube must have a high burst strength to withstand the pressures generated during interruption. Fuse elements are typically made from silver. Silver is the most common material used for high voltage fuse elements because of its predictable melting properties. Finally, an arc quenching filler is added to aid in the interruption process. During interruption the arc quenching filler is changed into an insulating material called a fulgurite [1].

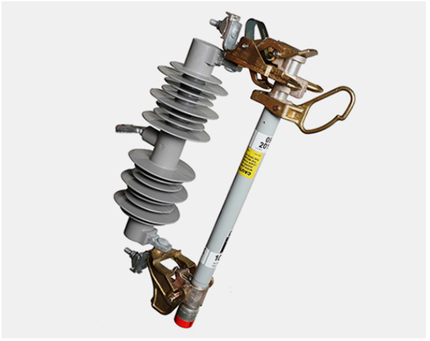

While current-limiting fuses are one type of non-expulsion fuse, SMD power fuses are also available [2]

Figure 1: S&C SMD Power Fuse [2]

Under maximum fault conditions, heat from the confined arc causes solid material in the large-diameter lower section of the arc-extinguishing chamber to undergo thermal reaction, generating turbulent gases and effectively enlarging the bore diameter so that the arc energy is released with a mild exhaust. Under low- to-moderate fault conditions, the arc is extinguished in the small-diameter upper section of the arc- extinguishing chamber, where deionizing gases are effectively concentrated for efficient arc extinction [2].

Another fuse type that is non expulsion is any under-oil fuse like you find in padmounted transformers or in CSP transformers. These are still expulsion fuses, but the energy should be contained in the housing [3].

Technical Readiness (Commercial Availability)

Current limiting fuses are a mature technology that is readily available. However, depending on the use case, there may be some important items to consider. For example:

- Methods to place current limiting fuses into and out of service.

- How close to load limits can current limiting fuses be sized? (smaller sizing may result in additional fault limiting)

- How will fault indicators and traditional fuses behave in areas protected by current limiting fuses?

Vendors with Hardware and Software

The following list of manufacturers is the product of an Internet search using a general description of the technology as the search term. Sometimes more than one variation on the search term is used. The objective is to identify the most demonstration-ready products available in the category. Toward assessing demonstration readiness, the manufacturer websites typically provide useful information such as writeups of successful use cases or field demonstrations, number of deployments, or other indicators. Where lack of information exists online, further inquiry is made by phone. Generally, one to three frontrunners emerge as being most ready for a field demonstration. Preference is given to manufacturers who sell to the United States, or, if emerging technology, those who have participated in US-based field demonstrations.

S&C

https://www.sandc.com/en/products--services/products/smd-power-fuses-outdoor-distribution/

Eaton

Implementations / Deployments

Non-expulsion fuse designs, including current-limiting fuses are widely used, taking into account their technical limitations.

References

[2] https://www.sandc.com/en/products--services/products/smd-power-fuses-outdoor-distribution/

[3] Email conversation, 1/19/2024 11:49 AM…tshort@epri.com