Charred Pole Integrity

Risk Reduction Category

Technology Description

The degree of damage imposed on utility assets by a wildfire depends upon the temperature of the fire and duration of its presence. Particularly vulnerable to wildfires are wooden poles and crossarms. In 2022, testing of wooden cross arms by the Western Fire Center, Inc. determined that the wooden crossarms retained specified strength (300 pounds at each end of the crossarm) for at least twenty minutes under a combination of radiant heat and flames. For exposure to flames alone, the crossarms retained strength for at least 30 minutes. By comparison, fiberglass crossarms collapsed within around seven minutes.[2]

While crossarms and poles may survive a fire, structural damage may not be evident and the long-term effects unknown as well. What is important to know is the degree of damage that is caused so that a decision can be made whether to leave the asset in service, inspect it again after a time, or replace it.

The United States Department of Agriculture, the Forest Service, Forest Products Laboratory, the Bureau of Land Management (Idaho, Boise District), and university collaborators published a report describing two strategies that may expedite such inspections and identify poles that are structurally unsound due to decay and those damaged during a wildfire.[3] Yet, many of these test devices may indicate weakness at the tested location only—requiring a succession of test points to provide an accurate assessment of the health of the pole.

EPRI has published several reports concerning utility pole tests over the last ten to fifteen years examining various methods of testing power poles for rot and insect damage. One such report examined fifteen non- destructive testing (NDT) methods of examining power poles. [7] Several technologies are compared in an EPRI report: Evaluation of Pole Inspection Technologies. [11] These include traditional methods such as:

- Sounding – Decaying wood sounds different than healthy wood when struck with a hammer. Experienced field workers can generally hear the difference.

- Boring – Drilling into the pole allows an inspector to locate and judge the approximate size of internal voids in the pole cross section.

- Excavation – Digging around the pole base and removing the soil allows inspectors to visually inspect and sound a below-ground portion of the pole.

- Circumference measurements – Measuring the pole’s thickness allows the inspector to quantify exterior cross-section loss of the pole.

- Visual inspection of the pole exterior – Some defects such as bends, burns, and rot can be visually identified.

- Some poles were tested to destruction to measure their remaining pole strength

The above methods require significant skill (pole sounding might require experience with 5,000 poles).

More modern methods include:

- Resistance drilling – This method is similar to boring but measures the physical resistance (torque required) to drill into the pole as a proxy for wood health.

- Sonic and ultrasonic – This method uses sound waves to measure the pole vibrations. It’s similar to sounding but leverages machines to perform the listening.

- X-radiographic tools – This method uses X-rays to produce images that can be used to characterize internal portions of a pole cross section.

- Gamma-ray densiometry – This method uses gamma rays to identify degraded areas in wood poles.

- Vibration analysis – This method is based on the understanding that the vibrational characteristics of a pole depend on its material properties, including the health, i.e., strength and stiffness, of the wood.

The above tend to be complex to use, costly, and lacking in field trials.

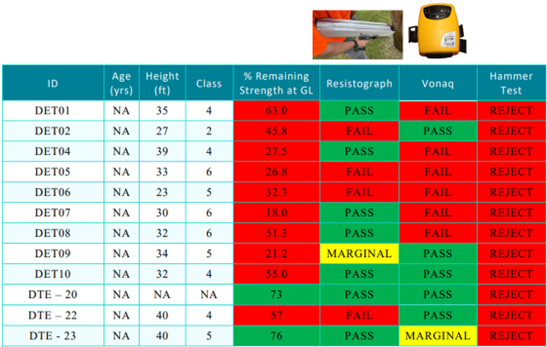

The EPRI report used several of the above traditional and more modern NDT methods—but not always on the same pole. An excerpt from the report shows a comparison of results (12 of 42) for the Resistograph, the Vonaq, and the traditional hammer test (not Thor) where they were tested on the same pole. The percent remaining strength was from destructive testing on the poles afterward.

Testing overall observed that the conservative and traditional sonic test tended to reject poles that might still be functional. The Resistograph identified decay at the groundline (where it was employed) but could not identify weakness further up the pole (such as charring); thus, a high number of false positives resulted. Of the poles tested by the Vonaq, roughly one third were “passed” where they might have been marginal or rejected—possibly due to close-by vegetation and/or truss-work above the groundline.

While many hours of training were required for the traditional methods, the two newer methods above required only a few hours of training and hands-on experience.

Of the above modern methods, the sonic methods may be most applicable to charred poles if only due to the likely change in cross-sectional area over the length of the pole which would affect pole strength and could be assessed using the Vonaq or Thor Pole tester. However, an electronic reference history of poles and corresponding sonic tests may be necessary to have an accurate assessment of the pole-strength degradation due to the wildfire.

Technical Readiness (Commercial Availability)

Professor Bruce Allison, working closely with the University of Wisconsin and the USDA Forest Products Laboratory and the University of Wisconsin, developed a stress-wave tool called Tree Check.[4] While initially intended for trees, this method can work for utility poles.

Another method involves using a small drill to assess the resistance of the wood to the drilling process. This resistance is much less for decayed wood than for uncompromised wood.[3] One version of this tool is shown below.

The same company producing the drill tool above also produces the IML Micro Hammer which measures the sound velocity in wood in response to hammer taps as illustrated below.

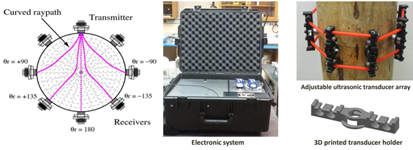

Another method developed for use with utility poles specifically involves using ultrasound. In 2009, Fernando Talavo wrote a thesis on using ultrasound to assess the structural integrity of utility poles [5] and went on to develop a tool for use in the field.[6] An ultrasound transmitter along with multiple receivers are used to assess the internal structure of the pole as shown below.

One apparently efficient development for utility pole testing might be the CXI PT5500 Pole Tester developed by Oxys Solutions (a Cinetix Group company). A probe is mounted on the pole at a measured height of 2 meters from the ground (for a charred pole, it may be necessary to scrape off a charred patch to get to uncharred wood at the 2-meter level). The person doing the test strikes the pole with a hammer. The probe analyzes the induced vibrations.

Another sonic method is the THOR Pole Tester by Groundline Engineering. This is a handheld device set—the specially designed hammer and sensor, and a tablet as shown below. One hand holds the sensor against the pole just above ground level while the hammer is struck on the opposite side of the pole (again, charred wood may have to be removed to expose solid wood). The tablet has the software that registers the sonic vibrations picked up by the sensor and may interact with the human tester to correct the sensor angle with the pole and/or the force of the hammer blow. Related software organizes all pole data with GIS coordinates which may be laid out on a map. [10] The charred wood on such a pole may have dampening effects. Many such tests (from the same pole tested previously or from a known good pole) may be required to gauge the results more accurately.

The following list of manufacturers is the product of an Internet search using a general description of the technology as the search term. Sometimes more than one variation on the search term is used. The objective is to identify the most demonstration-ready products available in the category. Toward assessing demonstration readiness, the manufacturer websites typically provide useful information such as writeups of successful use cases or field demonstrations, number of deployments, or other indicators. Where lack of information exists online, further inquiry is made by phone. Generally, one to three frontrunners emerge as being most ready for a field demonstration. Preference is given to manufacturers who sell to the United States, or, if emerging technology, those who have participated in US-based field demonstrations.

American Arborist – Tree Check

https://www.arborist.com/product/M130001-00/Tree-Check-Sonic-Wave-Decay-Detector.html

IML-RESI F-Series

https://www.iml-service.com/product/iml-resi-f-serie/

IML Microhammer

https://www.iml-service.com/product/iml-micro-hammer/

Vonaq Ltd - CXI PT5500 Pole Tester

https://www.etesters.com/catalog/ADBB546E-1422-08DF-AAC7-09285A92D511/vonaq-ltd/

THOR Pole Tester

References

[1] https://woodpoles.org/Issues/Fire-Protection

[2] https://woodpoles.org/portals/2/documents/WFC_Crossarm_Test_Report.pdf

[3] https://www.fs.usda.gov/features/reducing-wildfires-through-better-utility-pole-inspections

[4] https://www.wxpr.org/natural-resources/2017-11-14/sound-waves-what-trees-can-tell-us

[5] https://uwspace.uwaterloo.ca/bitstream/handle/10012/4588/FT-Thesis.pdf

[6] https://www.ndt.net/events/NDTCanada2016/app/content/Slides/12_Rodriguez-Roblero_Rev1.pdf

[7] A Review of Technologies for Detecting Decay or Insect Attack and Estimating Residual Wood Pole Properties. EPRI, Palo Alto, CA: 2020. 3002019302.

[8] https://www.youtube.com/watch?v=YQDaB_6bn3I

[9] https://www.etesters.com/catalog/ADBB546E-1422-08DF-AAC7-09285A92D511/vonaq-ltd/

[10] https://www.thorpoletest.com/

[11] Evaluation of Pole Inspection Technologies: 2023 Update. EPRI, Palo Alto, CA: 2023. 3002026858.