Overview

The Distribution Recloser Life Cycle Management project performs laboratory testing to understand the life-cycle characteristics of distribution reclosers along with a systematic teardown to determine potential future failure modes and degradation mechanisms. This research will help utilities inform specification and selection for new reclosers and give utilities insights into potential future challenges with widescale recloser deployments.

Background

Grid modernization initiatives are underway at many utilities to prepare the distribution system to meet future needs of customers and integrate distributed energy resources while maintaining a highly reliable and resilient system. Distribution automation is a key component of these modernization efforts that allows utilities to monitor, operate, and optimize their systems.

The use of reclosers is critical to automating the distribution system. Reclosers are for fault isolation to avoid extended outages due to momentary interruptions and provide added system awareness when integrated with distribution management systems. Reclosers operate infrequently but must do so reliably and consistently. Manufacturers perform design and production tests according to industry standards, but these tests typically do not include analysis of the long-term performance of the design and materials used to construct the device.

Project Approach

The Recloser Life-Cycle Management project consists of four tasks:

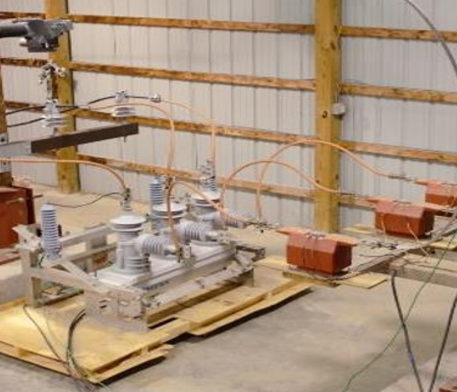

Functionality Tests

This task tests some of the basic functions of a recloser.

Sensor Accuracy Testing

This task tests the accuracy of the recloser’s embedded and external voltage and current sensors. The reclosers are energized at different voltages and load currents. Measurements from the recloser control are compared with calibrated instrumentation to calculate a percentage error.

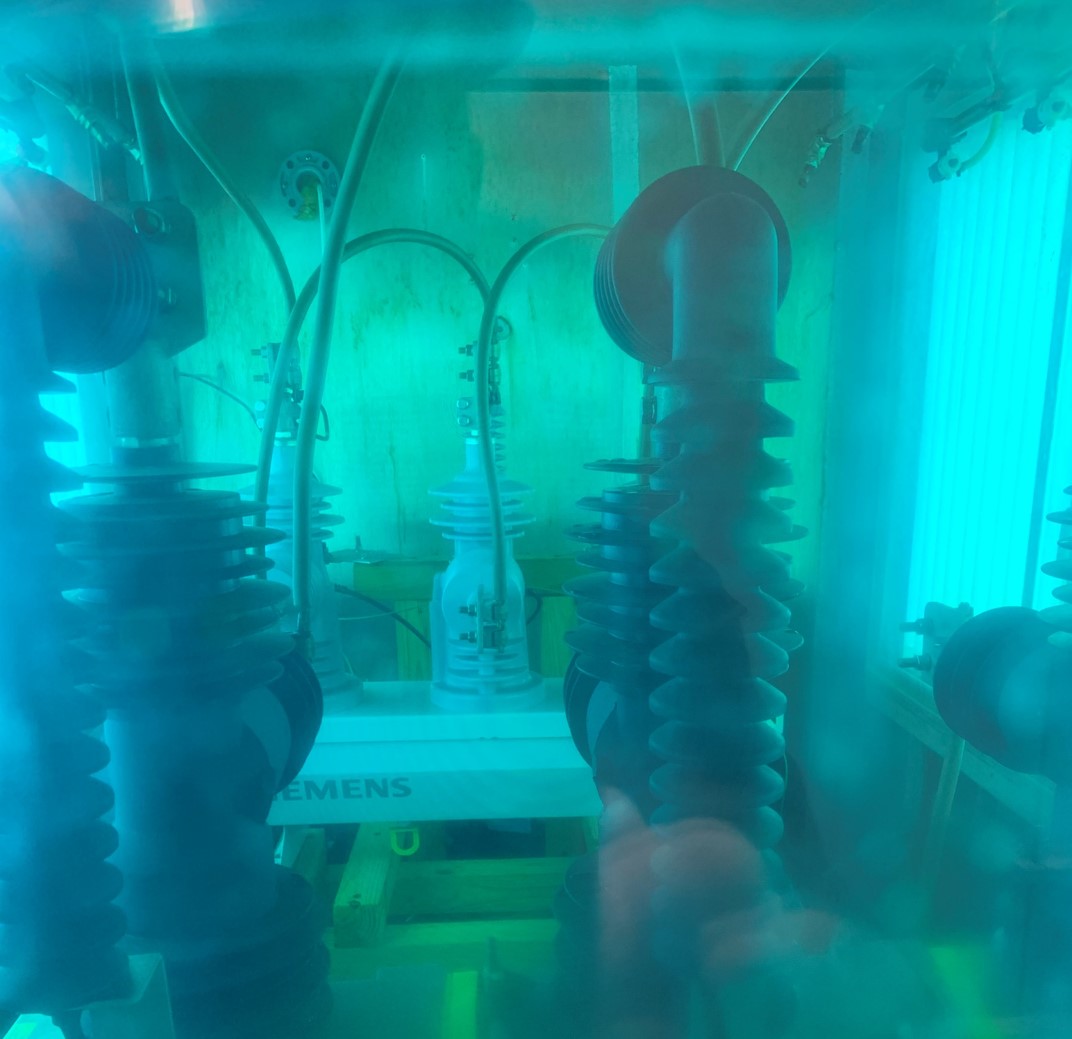

Accelerated Aging

This task subjects reclosers to an accelerated aging for a period of 2,500 hours. The recloser are energized during the aging process. The environmental stressors include rain, salt fog, humidity, thermal cycling, and UV.

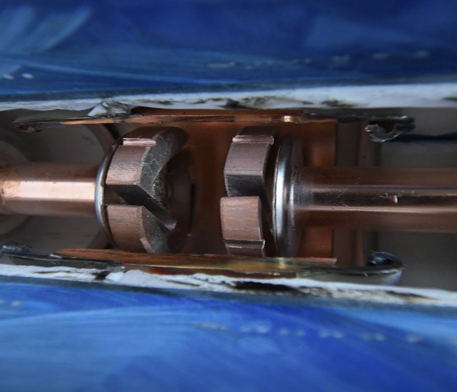

Systematic Teardown and Analysis

This task systematically dismantles each recloser after the completion of testing and inspects it to identify degradation. Material samples may be also be taken from the recloser for further lab analysis.

Benefits

Utilities may benefit from this research through enhanced knowledge of recloser aging, resulting in more informed decisions related to the acquisition, operation, maintenance, and disposal of distribution reclosers. Utilities can apply the results to promote a more reliable, safe, and cost-effective recloser fleet. An additional benefit from testing may be an enhanced recloser aging test protocol. This could enable more effective testing of distribution line reclosers and future applications to other equipment.

Project Price, Status, and Schedule

The cost of the project is $60,000 per participant. This project qualifies for Self-Directed Funding (SDF) or Tailored Collaboration (TC) funds. Project testing began in mid 2019 and the testing will be completed by the end of 2022. Each project participant may provide one recloser for laboratory testing. All participants in the collaborative project receive the results from each tested recloser. The project plans to test up to 12 reclosers and will be continuing through 2022.

Who Should Join

Utilities that are developing recloser procurement specifications or are in the process of new recloser deployments could benefit from joining the project. Also, utilities who are developing inspection and maintenance practices for existing recloser fleets or who want to better understand recloser life cycle may also benefit from the project.

Contact: Jason Anderson