Avoiding Conductor Slap

One electrical line phenomenon that is commonly associated with power line faults is referred to as conductor slap where two or more of the wires come in contact during either wind gusting or from electromagnetic pendulum forces during sequential faults. When the wires contact one-another they can throw sparks and molten metal onto the vegetation below. Interestingly this happens quite often on bare overhead conductors and is not well understood by field crews that don’t find evidence of a fault when they patrol the line and many times record the breaker lockout incident with a cause code of “No problem found.”

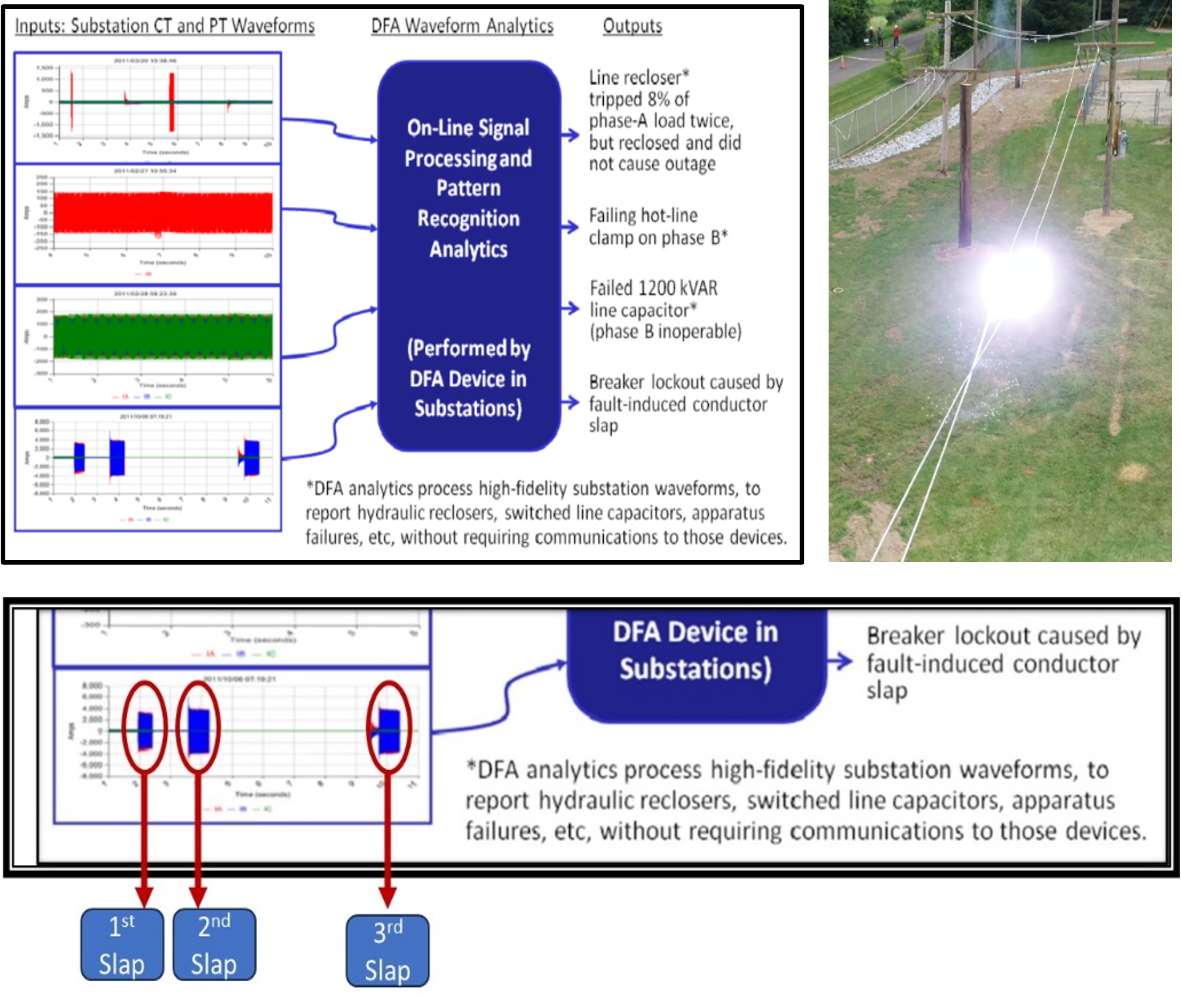

Even with the “no problem found” result, the following pattern of currents and voltages would be recorded by a power monitoring device. To supplement the narrative, the following figure and the (lower blue trace) in The Figure contains a power quality recording from a magnetically induced conductor slap incident and can be described with the sequence description that follows the image.

- An initial fault occurs downstream of a protective device from some initiating event such as a tree branch, or a ballon, or an animal. When the initial fault occurs, the wires have equal and opposite fault currents, and this causes the wires to magnetically oppose on another and to swing apart in a pendulum motion. For a typical power system, the upstream protection senses the fault current and opens to clear the fault - leaving the wires heated up, stretched out a foot or more from the heat, and still swinging. In the figure (bottom blue trace) the first current increase on the left side shows this initial fault followed by zero current once the protective device opens.

-

When the protective device re-closes back in (a few seconds or so later) the upstream conductors (somewhere closer to the substation) can swing together and cause a new fault, this time with even higher currents than the previous event. This can be seen as the second current increase in the blue trace and again a protective device opens and the currents go to zero again

-

After the protection recloses, the conductors slap together for a third time. After enough unsuccessful reclose attempts, the main breaker opens – locking out the circuit and the currents and voltage go to zero.

The same kinds of outcomes may occur with wind caused conductor slap, and for both types (magnetic and wind caused) there may be several different variations and combinations of fault – reclose – fault – reclose – lockout that can and do happen. The key takeaway here is that this sequence of events, and the current magnitudes and the patterns are detectable, predictable and can be turned into recognition algorithms. In fact, not only can the power signatures for conductor slap be patterned, but the same patterning and algorithm development approach works for another dozen different kinds of fault incidents and fault causes. Further, taking the time synchronized voltage and current data from some of the other line sensors, either upstream or downstream of the fault location, make the algorithms even more accurate and insightful and even more useful for fault and ignition risk analytics. For more on the conductor slap topic visit this EPRI link.