Hybrid Undergrounding RD&D

Undergrounding power lines to avoid wind, ice, tree, and airborne ignition incidents is an expensive but well accepted approach that has been documented to improve reliability, decrease fault counts and minimize ignition risks. Traditional excavation methods continue to present many challenges including:

- Rocky geologies that increase the time and cost of excavation

- Time consuming permitting for archeological and religiously sensitive areas

- Removal or treatment of excavated soil adds cost and time

- Presence, of contaminants extends project timelines or may require re-routing

Hybrid undergrounding where the lines are neither left in the air nor trenched and buried underground is a compelling concept.

The objective of this proposed RD&D is to demonstrate hybrid undergrounding solutions that require minimal or no excavation and to simultaneously eliminate weather and tree exposure. Virtually any approaches that provide physical protection to the cables and the public, without excavation of the subsoil, could provide additional options in the undergrounding toolbox for utilities.

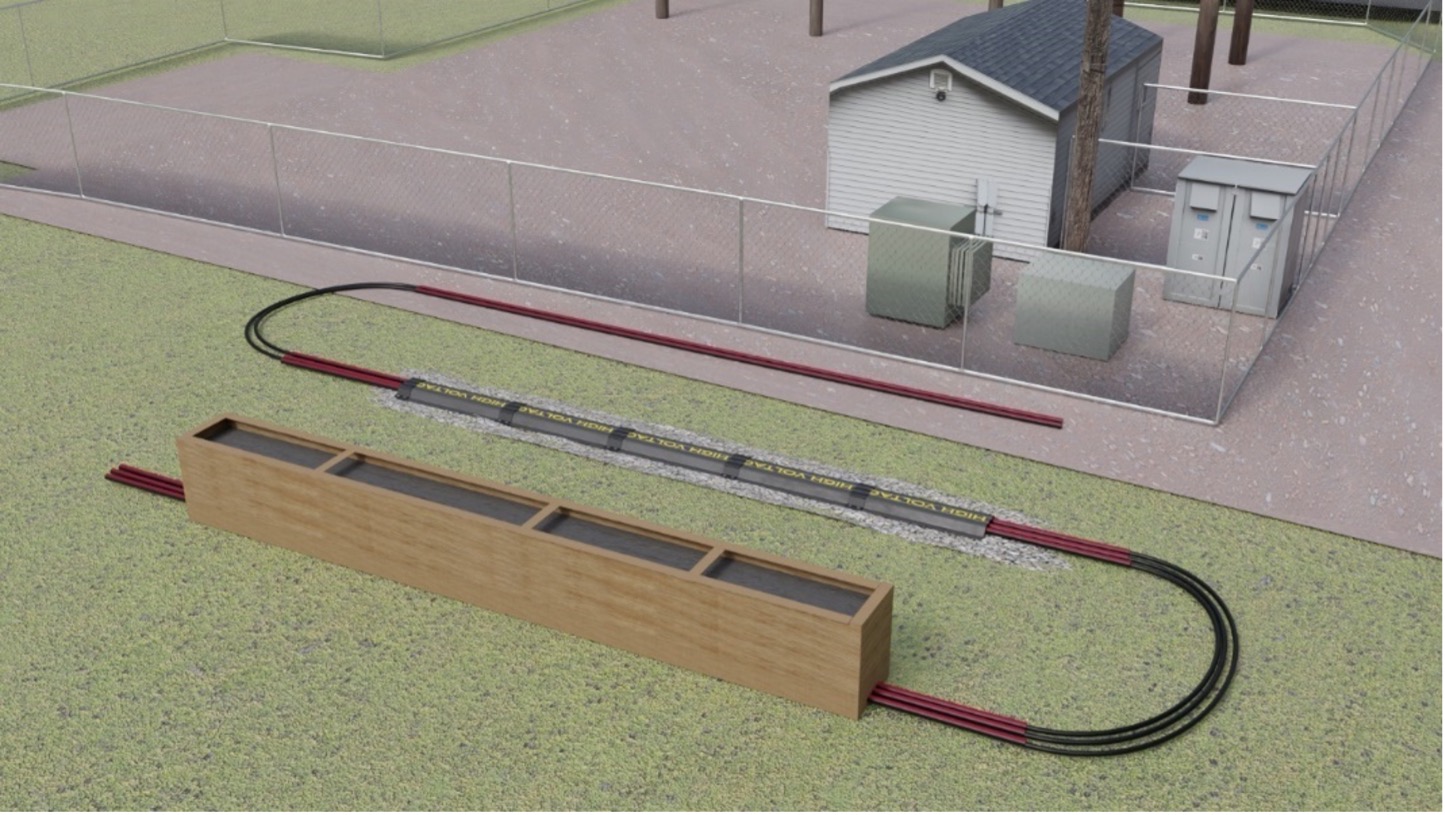

One such system referred to as GLDS or Ground Level Distribution System is being demonstrated in the field at one utility. The system is additionally being evaluated in a laboratory environment at the EPRI Lenox test facility to begin answering some key resilience questions including:

- How does the encasement on the cable impact its current carrying capacity (ampacity)?

- How well do the GLDS protective structures protect the cable system from vertical impacts, such as tree impacts, and crush events, such as vehicles driving over it?

- What is the longevity and survivability of GLDS structures?

- What effect do repairs to the top cap and geopolymer concrete have on the strength of the structure?

- How may the cable system be maintained over its life?

Overall, the 2024 testing is designed to provide early insights into questions associated with safety, robustness, fire immunity, ampacity, thermal performance, and fault protection. This leads to a compelling opportunity for EPRI, DOE and the power industry to accelerate the use of GLDS and similar hybrid undergrounding approaches that can serve to meet industry objectives to reduce ignition incidents exponentially.

What is needed to accelerate the industry toward the 2030 Vision?

The proposed RD&D moving forward is to collaborate with ten or more electric service providers to install either GLDS or a similar hybrid undergrounding variation in their service territories and to monitor these systems over at least one full vegetation management cycle of four-to-five years.

The Task set would focus on documenting the full process required at each utility to first identify the candidate high risk areas, attain the permits and right of ways as needed, document the full project procurement and construction process, and to then document the before and after fault count and ignition incident statistics.

Field demonstrations should consider unique application challenges to answer basis questions around how feasible it is to use the technology in different terrain and geological scenarios. For example, suitability for:

- Granite, rocky, and mountainous terrain

- Areas where the soil should not be disturbed

- Wet (swampy) areas

- Across ravines and small streams

- Culturally sensitive locations

- ROW restricted locations

- Understanding vandalism challenges and accidental public issue

- Road crossings

- In or beneath sidewalks

Conceptually the GLDS or similar technologies could be installed in parallel with an overhead line and half the load could be directed on each pathway. Over time fault counts and reliability numbers could be compared between the two systems. Additionally, it is probably best to find a location where no pedestrian or vehicular traffic is anticipated in an abundance of caution.

Concurrently, EPRI and at least one of the National Labs could perform accelerated lifecycle testing and work with the utility participants to ideate on splicing and protection strategies that have not yet been conceptualized or vetted. The following Table summarizes these follow-on recommendations.

Which 2030 Future States are Impacted by this Work?

This work addresses the following 2030 future states from the DOE EPRI report on wildfire risk reduction opportunities:

- Access to comprehensive selection of hybrid underground construction options

- Flame immune power system hardware

The work additionally supports and resolves the challenges associated with other overhead hardening options that don’t achieve high 90’s percentile ignition risk reduction.