2022 Distribution Automation Project Tasks

Distribution Automation Project Tasks for 2022

Distribution automation (DA) enables remote, real-time monitoring, operation, and optimization of utility distribution systems. DA assets are becoming more common, and the number being deployed is growing. It is important for utilities to actively manage DA assets due to their prevalence and their criticality to grid modernization efforts.

The objective of this research is to provide member utilities with advanced knowledge, technologies, and tools that enable them to make informed decisions regarding the life-cycle management of Distribution Automation assets.

The current research needs include understanding failure and degradation modes; improved inspection techniques and maintenance procedures; tools and technologies to remotely manage settings and firmware; reference books, asset databases, practices, and guidelines to assist with asset deployment and management; and a collaborative environment for sharing lessons learned and leading practices.

This project focuses on the assets that utilities use to automate the distribution system. These assets might include switching devices (for example, reclosers, sectionalizers, enclosed switches, advanced lateral devices, and padmount switchgear) and their controls; distribution voltage and current sensors; and voltage optimization controls (capacitor bank and voltage regulator controls) and related components. Research will be provided in multiple forms, including:

Laboratory Evaluation and Assessment: This task plans to define test protocols, develop the capabilities, and perform laboratory testing of distribution sensors, controls, and switching devices especially related new designs. Test results aim to inform utility decisions regarding specification and selection. In 2024, the plan is to perform life-cycle testing on a S&C IntelliRupter and perform sensor accuracy testing on Gen2 Lindsey sensors.

Recloser Failure Analysis: This task investigates the failure mechanisms of distribution reclosers. The research intends to analyze failed units to understand failure modes. Also, failure information will be collected from various utilities to gather additional information on the failure modes of reclosers. The results could reduce the likelihood of failure and aid utilities in optimizing life-cycle performance.

Underground Distribution Automation: This research investigates the life-cycle performance of medium-voltage underground DA fault interrupters and switches. As automated devices are increasingly being added to underground system, research is planned to focus on the expected long-term performance of the automation associated with underground devices, including investigation of degradation and failure modes and the need for standardization. Research results can inform equipment specifications and inspection and maintenance approaches, reducing the likelihood of failure and aiding utilities in optimizing the life-cycle performance of these devices. This task will be a joint task with P180.002 Underground Distribution Assets.

Cabling and Connectors for Automation Equipment: Automation controls are typically connected to devices at the top of the pole using a multi conductor control cable that is terminated on both ends with a multi-pin connector. Control cables have been found to cause mis-operations of automation device, inconsistent or inaccurate measurements from sensors, and reporting of improper statuses from the device. This task plans to investigate control cabling to understand failure causes and develop an accelerated aging test to help inform specification and selection decisions related to control cables and connectors. The task also aims to understand practices related to installation and maintenance of control cables.

DA Visual Inspection Field Guides: Visual inspections, whether performed by a human or artificial intelligence (AI) system, require training to detect specific anomalies. To assist with this, EPRI is developing guidance on what to look for and how to act upon visual inspection results from DA assets. This field guide is planned to include images that illustrate various conditions and factors that commonly affect DA assets.

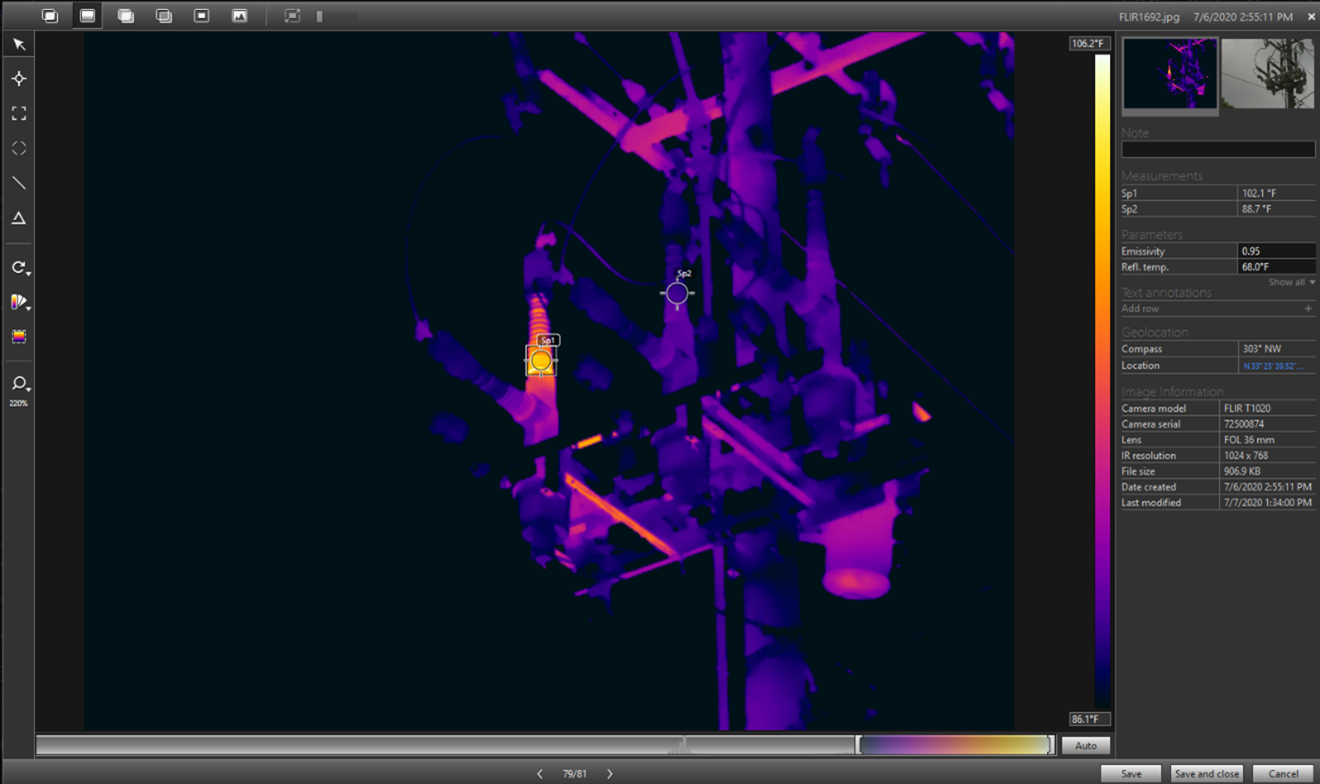

Advanced Inspection Technologies & Tools and Health Monitoring: The widescale deployment of automation assets comes with additional challenges to utilities of how to inspect and maintain this large fleet of complex equipment. This task plans to investigate technology and tools to assist with inspections of newly installed automation assets, routine inspections, and failure investigations. The technologies evaluated may range from handheld tools to detect infrared radiation or partial discharge from specific components to the use of unmanned aerial vehicles (UAVs) for full imaging of a DA installation. Additionally, this task will investigate and demonstrate post data management and visualization tools.

Power Electronic Devices on the Distribution Grid: Power electronic devices represent a new class of asset that have yet to be widely deployed on medium and the low-voltage distribution systems. These devices could enable a more flexible grid through additional control and visibility, especially at the edge of the grid. In 2024, this task plans to scout and document potential technologies, while developing laboratory test approaches to investigate device functionality and long-term performance.

Technology Scouting: The pace of change in distribution technology is accelerating with new technologies, approaches, vendors, and service providers entering the market and offering new solutions. This research will scout new technologies for distribution automation and identify opportunities for further investigation and demonstrations.

EPRI Distribution Automation Guidebook: EPRI continues development of a comprehensive DA guidebook, with a current focus on reclosers, recloser controls, and distribution sensors. Report contents include a focus on specification, selection, installation, operation, and maintenance.

DA Practices: This task investigates leading practices for management and field operation of DA devices. Focus areas include DA asset design, provisioning, installation, commissioning, inspection, maintenance, and troubleshooting. These practices are gathered through broad utility surveys and targeted interviews to discuss the utility’s practices in depth.

For more information on the 2024 plan for distribution automation, contact Jason Anderson.

The proposed research on DA assets is expected to produce the following value for participating utilities:

The Distribution Automation Task Force advises the Distribution Automation Assets Project (P180.003). This task force consists of utility subject-matter experts in areas related to automation, grid monitoring, and control. The task force is focused on the life-cycle of automation assets including switching devices, sensors, controls, and voltage optimization devices. This task force meets several times per year by WebEx or in person. There is usually one in-person meeting per year held in conjunction with the other P180 task forces.

Members are encouraged to participate in several ways:

This task force is also a good opportunity to meet automation experts at other participating companies.

Who can attend task-force meetings?

Are there specific membership requirements?

How do I join this task force?

Can my company have more than one task-force member?

Can I share task-force material within my company?

Can I share task-force material outside my company?

Are discussions covered by a non-disclosure agreement?

If my company isn’t funding this, how can I sign up?

|

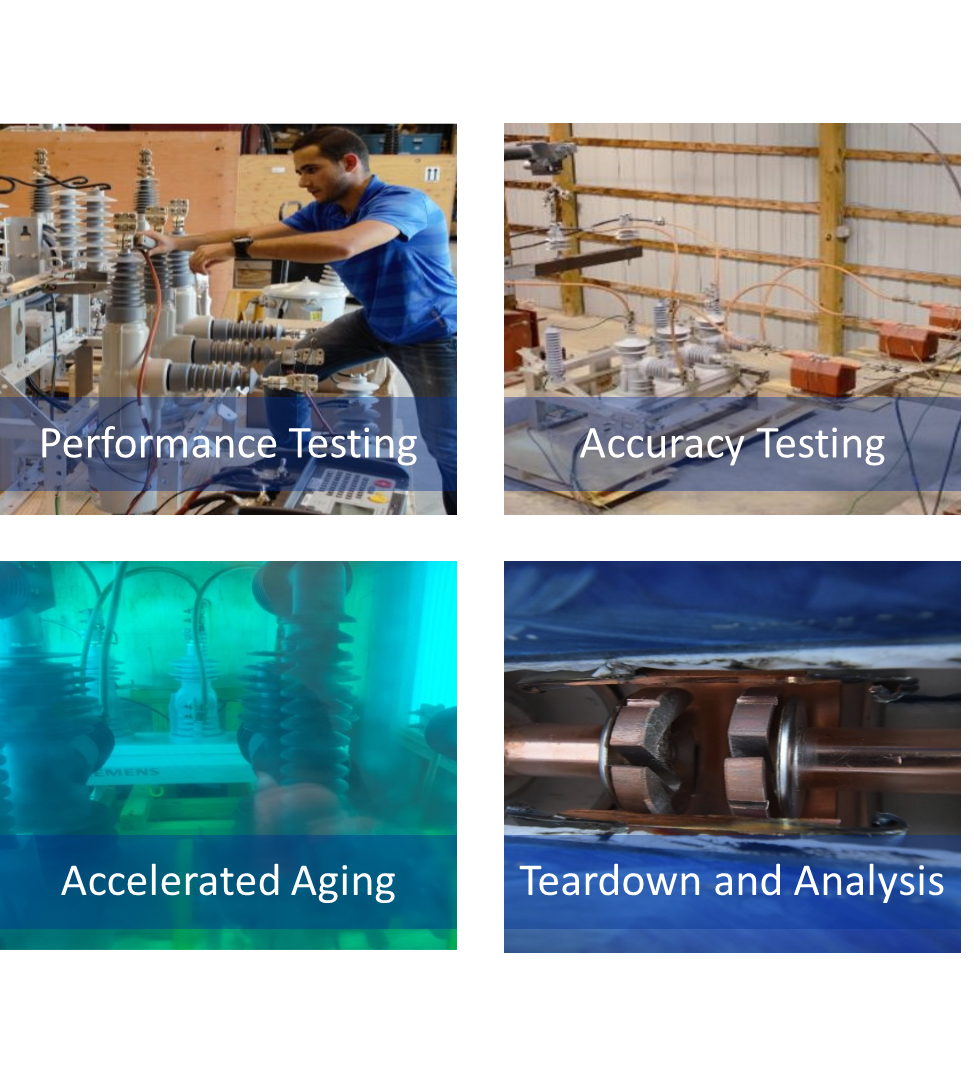

Distribution Recloser Life-Cycle ManagementUnderstand Future recloser performance … to make better decisions Today!Reclosers are an essential component of utility grid modernization efforts. EPRI is performing laboratory testing including functional tests, the accuracy of embedded and external recloser sensors, and accelerated aging testing on many different reclosers. Once testing is completed the recloser will be systematically dismantled to look for potential future degradation mechanisms. The goal of this work is to help utilities to make informed life cycle management decisions regarding distribution reclosers

The outcomes from this project include:

|

|

Alternative Technologies for Recloser Backup PowerImprove recloser backup power to reduce O&M costs and ensure the reliability benefits of automation.Many utilities have recently completed or are in the process of wide-scale deployment of distribution reclosers as part of grid modernization efforts. Experience has shown that battery maintenance represents the largest O&M expense related to reclosers. As such, these expanded deployments may increase O&M spending for battery maintenance. The backup batteries in most controls are valve regulated lead acid batteries (VRLA) and this has been the standard for many years. There are several new potential energy storage technologies that may also prove useful for these applications. The objective of this project is to investigate the suitability of alternative energy storage technologies to provide recloser backup power. This new project will consider several areas related to backup power systems in distribution recloser controls.

The following tasks are planned:

|

For more on supplemental projects, see here. To discuss project ideas, please e-mail Jason Anderson.

EPRI offers utilities the ability to send in failed automation equipment such as reclosers to perform diagnostics, and systematically teardown the equipment to ascertain the root cause of failure. This process typically takes the following form:

Equipment failures can often pose safety risks. In both the P180.001 Overhead and P180.002 Underground projects, the fundamental deterioration and failure modes of equipment are evaluated.

The P180.002 Underground project is also covering issues with manhole explosions from flammable gases and faults.

Distribution Automation Project Tasks for 2022

Distribution Automation Project Tasks for 2023

Distribution Automation Project Tasks for 2024