Recloser Testing

Industry Challenge

Reclosers are an essential piece to utility grid modernization efforts. Reclosers are used for fault isolation to avoid extended outages due to momentary interruptions and to provide added system awareness. Reclosers operate infrequently but must do so reliably and consistently. Manufacturers perform design and production tests according to industry standards, but these tests typically do not include analysis of the long-term performance of the design and materials used to construct the device. The distribution recloser market has many options available from various manufacturers with new and updated designs coming to market often.

Utilities are challenged with the need to make specification and procurement decisions with limited data to support the decision of which reclosers to acquire.

EPRI’s Response

EPRI has developed a research approach to assist utilities in making recloser asset lifecycle decisions. There are two components to the research:

-

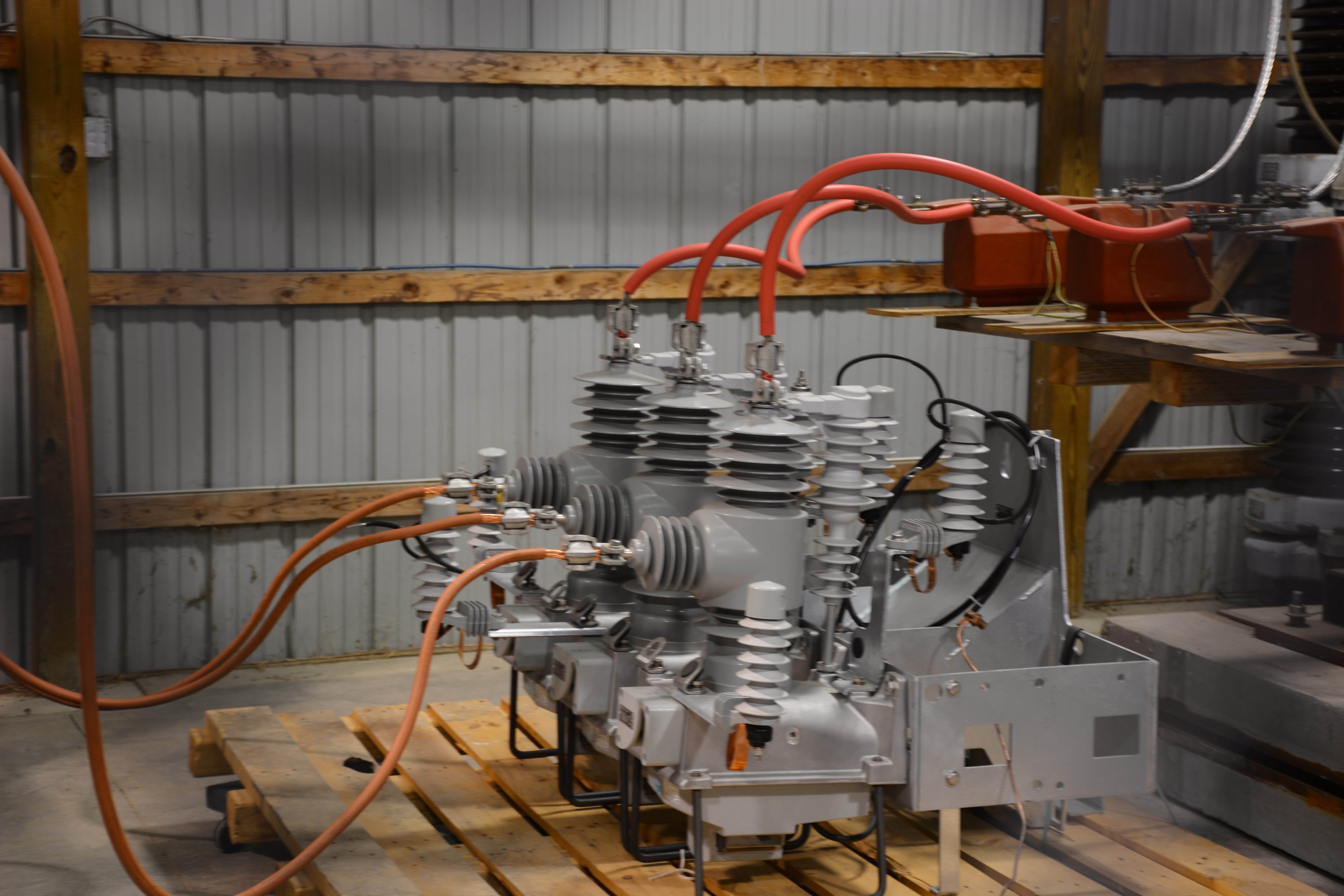

Laboratory Testing and Design Review – The purpose of the testing and design reviews are to understand how new reclosers age and degrade over time. EPRI’s preference is to receive reclosers from utility stores to put through this test protocol. The following is the protocol used for each recloser received.

- Functionality Testing – A series of tests to verify their basic operation. This testing includes its ability to interrupt fault current, perform its sequence of operations as programmed, a voltage withstand test and a measurement of the resistance of its main circuit path.

- Sensor Accuracy Testing – Testing to understand the accuracy of the recloser’s embedded and external voltage and current sensors. The reclosers are energized at different voltages and load currents. Time synchronized measurements from the recloser control and calibrated instrumentation are compared to calculate a percentage error.

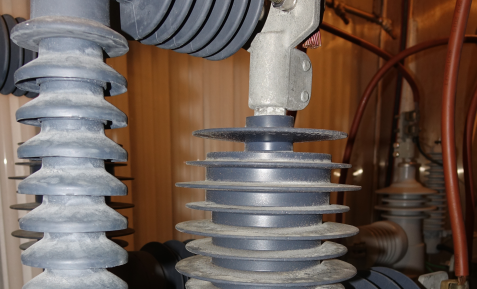

- Accelerated Aging – Reclosers are subjected to an accelerated aging protocol for a period of 2,500 hours. The recloser is energized at rated voltage with current passing through it during the aging process. The environmental stressors include rain, salt fog, humidity, thermal cycling, and UV.

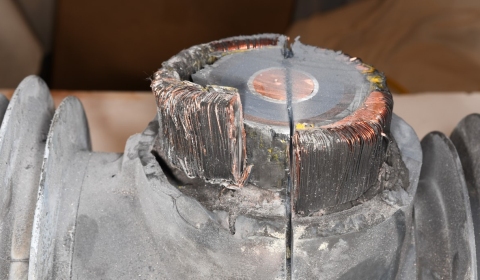

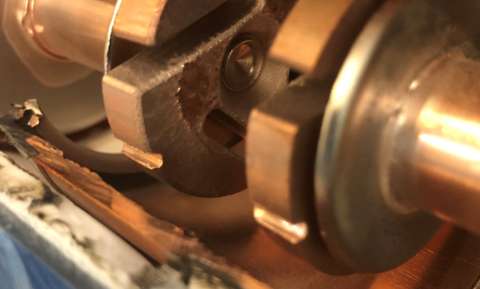

- Systematic Teardown and Analysis – Each recloser is systematically dismantled from the outer housing to the vacuum interrupter after the completion of testing and inspected to identify degradation. Material samples may also be taken from the recloser for further chemical analysis.

-

Failure Analysis – The purpose of this is to identify and understand the primary failure modes and degradation mechanisms of reclosers that are sent to EPRI from the field. The failure analysis process includes diagnostics, and systematically teardown the equipment to ascertain the root cause of failure. This process typically takes the following form: received.

- Photo and Video Documentation – Capture visual evidence prior to any unit disassembly

- Electrical Tests – Determine status and operability of the recloser electrical components.

- Teardown – The recloser is systematically disassembled to identify the cause of failure.

- Analysis – Findings are reviewed, chemical analysis is performed on samples from the recloser, and potential failure modes identified

Progress, Results, & Next Steps

EPRI has been performing research on reclosers for the last decade first with teardowns of failed units and then the development of a laboratory testing protocol for brand new reclosers to help utilities understand future performance. The development of processes for understanding how reclosers may perform in the future along with a robust knowledge of failure modes has assisted EPRI members with critical information as they have rapidly deployed hundreds or even thousands of new recloser in the last decade. From the failure analysis there has been several key failure modes and degradation mechanisms identified are:

- Moisture Ingress

- Wildlife

- Lightning

- Manufacturing Defects

The laboratory testing has identified opportunities for improvement in recloser designs that members are able to go back to the manufacturer and use the information to The new steps in this research are to continue to offer utilities the ability to send in new reclosers as they are updates to existing designs or brand-new designs coming to market. EPRI will also continue to perform teardowns to help utilities get a third-party unbiased information about failures of reclosers.

How to Use the Research

Utilities informed decisions related to the acquisition, operation, maintenance, and disposal of distribution reclosers. Utilities can apply the results to promote a more reliable, safe, and cost-effective recloser fleet.

How to Get Involved

Get involved in the DA research specifically the Distribution Automation Assets project (P180.003) and Recloser Life-Cycle Management supplemental project. EPRI plans to continue after the supplemental is completed to continue to evaluate new designs and perform failure analysis.