Lenox T&D Lab

The Transmission & Distribution laboratory in Lenox, MA provides a unique test facility for a variety of T&D research topics. Explore the laboratory below by clicking the popover (red dots) at a selection for the test sites. Click the popover to keep the popover open.

- Arc Flash

- Burndown of bare and covered conductors

- Flammability of equipment under fault condition

- Damage to crossarms and insulators under fault conditions

- Performance of sensors during faults

- Grounding and stray voltages; step and touch voltages during faults

- Evaluation of vegetation faults

- Fuse cutout and single-phase recloser performance

- Conductor slap

The test fixture applies a three-point bending test to composite crossarms. This test includes the capability to enclose the crossarm and elevate the temperature to investigate load-deflection characteristics in extreme heat.

Outdoor DA test area for long term testing of automation components, to understand the performance overtime.

Lightning and grounding testing up to 800kV to improve distribution automation equipment reliability.

Three phase accuracy test set is used for testing distribution sensors and can be energized at 19.2kV with current from 0A to 600A.

This facility is an MV and LV test area and an outdoor aging yard for distribution assets.

EPRI can configure this multi-purpose test area to perform cantilever pole strength testing. This testing is helping utilities learn more about the quality of pole inspection by comparing field assessment with actual remaining pole strength as determined through laboratory testing.

The energized-downed-conductor area has been used to record signatures of live, downed conductors. Several relay and recloser technologies for detecting these high-impedance faults have been tested. Multiple scenarios are available, including multiple voltages and different surfaces.

This capability has also been used to evaluate vehicle grounding and what happens when a vehicle becomes energized. This includes step and touch voltages around energized vehicles.

This capability has also been used to evaluate vehicle grounding and what happens when a vehicle becomes energized. This includes step and touch voltages around energized vehicles.

Three phase reconfigurable transmission line more than 500 meters long.

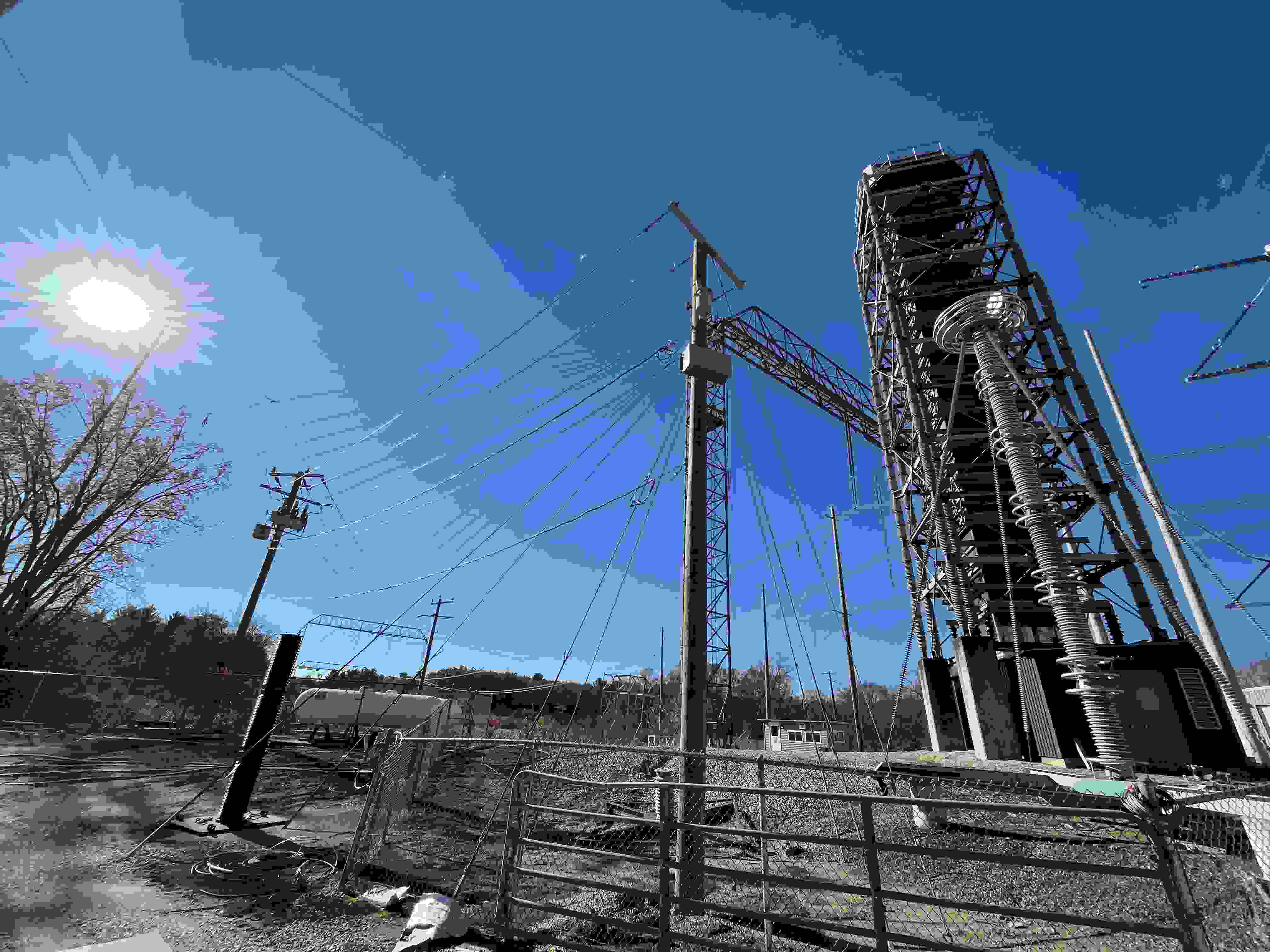

Three impulse generators are located in the EPRI Lenox laboratory, the largest of which is the 5.6MV tower which simulates lighting and switching surges for performing component testing and insulation coordination mapping.

Resiliency & reliability testing of full scale distribution structures using simulated tree-strikes and falling branches.

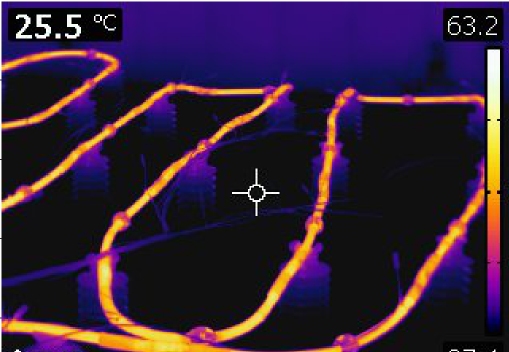

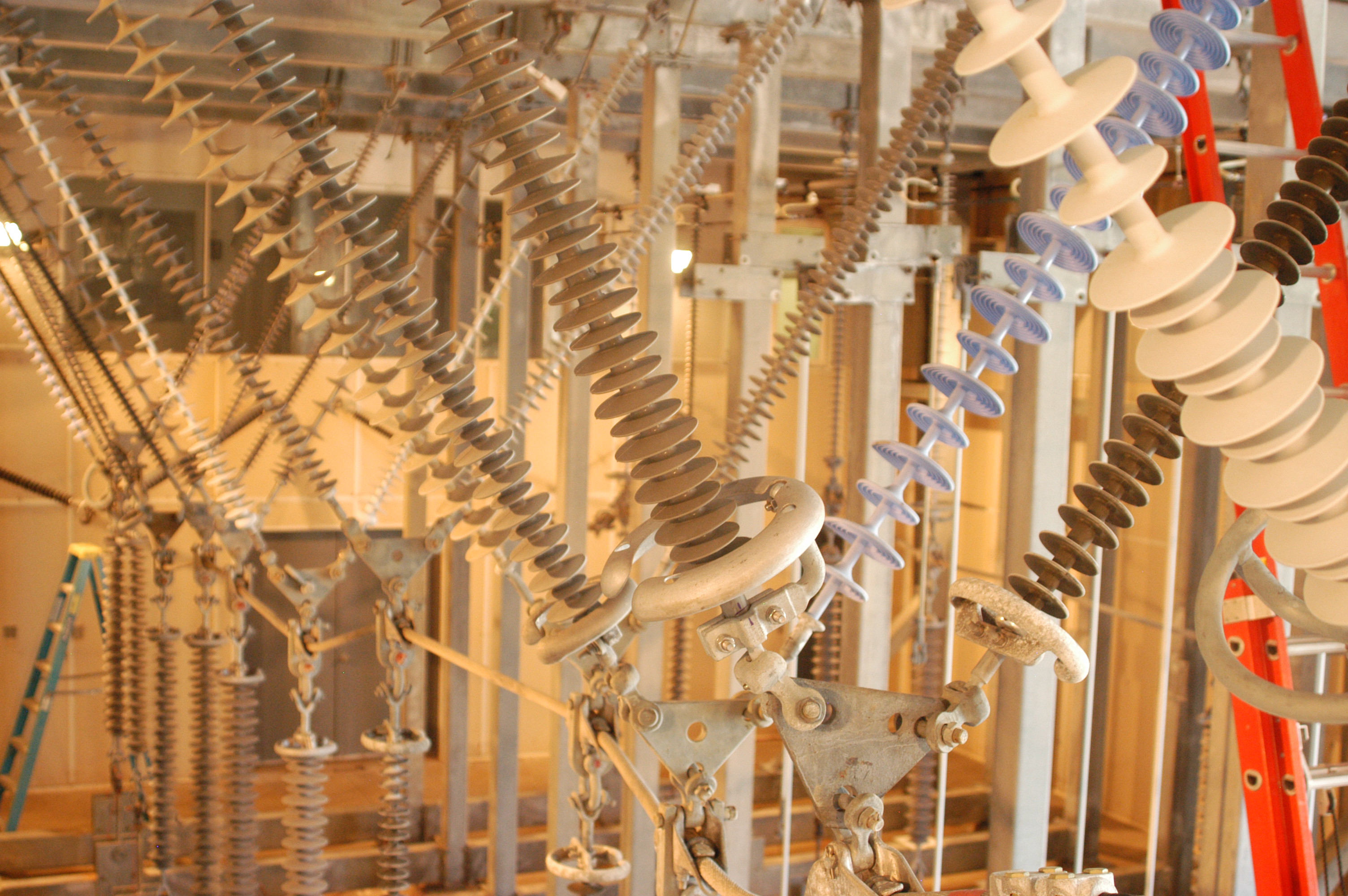

Research substation to investigate component, monitoring, and diagnostic performance.

Drone test site to understand aircraft and payload performance in electric environments.

Long-term test fixture to understand degradation and inspection methods for low voltage connectors.

Accelerated environmental aging is performed on full scale composite (fiberglass) poles and crossarms as well as small scale samples to determine changes in their mechanical and electrical properties.

Test Facility designed to replicate user defined human and animal perceptible shock scenarios. This includes ability to simulate concerns associated with urban shock hazards, overhead distribution stray voltages and swimming pool electric shock concerns.

EPRI has the capability of performing tests on transmission line insulators with guidance from ANSI C29.2B Section 8.3.4 –“Combined mechanical and electrical strength tests”

The accelerated aging chamber is 40 ft wide × 60 ft long × 20 ft high. A computer-controlled environmental system simulates a defined climate inside the aging chamber by varying temperature, clean fog, salt fog, clean rain, UV radiation, and humidity.

Hover over these links to locate a test site on the map above:

Arc fault tests | Arc flash | DA Full-Scale Test Area | Composite Structure Aging | Composite Crossarm Test Area | MLV Yard | Stray and Contact Voltage Test Infrastructure | Distribution Automation Loop | MV Termination Cable Testing | Pole Strength Testing | Full-scale Structure Tests | Energized Downed Conductor | Vehicle Grounding | 23-kV loop | Reconfigurable Transmission Line | DA Lightning & Grounding | 5.6MV Impulse Generator | Drone Test Yard | 138kV Test Substation | Above Ground Test Vaults | Underground Explosions Tests | Low Voltage Connectors | MTS M&E | Aging Chamber | New 12 stage IG