EPRI T&D Asset Forensics & Failure Analysis

Contact: Joe Potvin (jpotvin@epri.com)

Transmission and Distribution (T&D) asset failures can significantly impact system operation, reliability, and safety. These failures are frequently difficult or impossible to predict, and they can sometimes seem random. In reality, these failures are driven by degradation mechanisms and stressors that lead to specific failure modes. Even sophisticated online monitoring data may not tell the whole story. A forensic analysis may be the best opportunity to learn why a component failed. This helps you prepare for the future by improving specifications, inspections, or maintenance practice.

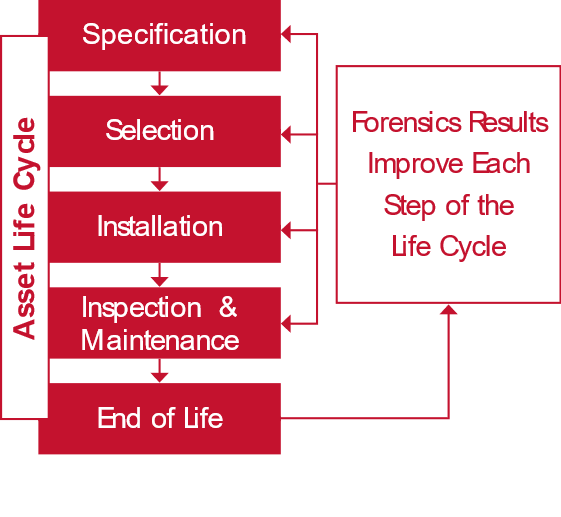

Use the Past to Improve the Future

The pace of utility operations is fast – especially when you are responding to an equipment failure. By using the EPRI team to perform a forensic analysis, you not only free your team to focus on the critical work of preparing for the future, but you are also equipping them with lessons from the past. Learning from past failures gives you new insights so that you can:

- Improve specifications – Whether it is a design issue, a materials issue, or an environmental issue, there may be an opportunity to prevent future failures by updating your specifications based on causes of previous failures.

- Improve work practices – Workmanship issues during installation, operations, and maintenance are difficult to diagnose and correct without data from a forensic analysis.

- Improve inspection capabilities – A forensic analysis is a critical step in understanding how assets age and fail. This information directly informs inspection tools and practices that can improve performances.

The Forensics Process

A proper forensic analysis of a transmission or distribution component is a multi-disciplinary exercise that requires deep expertise across a broad range of engineering and material science. While each investigation is unique, EPRI applies a rigorous, scientific method that can include a multitude of approaches such as:

- Materials analysis – Even simple components can be made of complex materials with unique performance characteristics. A thorough analysis of each material not only increases understanding of the component itself, it can also expose byproducts produced during failure.

- Mechanical & Electrical Testing – Depending on the component, a series of mechanical & electrical tests can begin to identify and locate the point of failure.

- Detailed dissection – In many cases, a thorough and methodical dissection of the failed component can expose evidence of design, manufacturing, or installation errors. It takes time, dedication, and an eye for detail, but the effort is typically worthwhile.

Expertise

EPRI engineers test and analyze T&D assets every day. The team has decades of experience in understanding asset design, performance, degradation, and failure. We have experts across many assets and scientific disciplines, such as transformers, circuit breakers, connectors, corrosion, underground equipment, and distribution automation. This expertise, coupled with the EPRI labs, means that the team can perform the forensic analysis, and put the results into context to help you understand how to turn the insights into action.

Examples of T&D Asset Forensics & Failure Analysis

Tools and Capabilities

The EPRI laboratories can analyze a wide range of components and assets. We have a vast array of advanced inspection and analytical tools at our disposal, such as:

- Stereo microscope

- Scanning electron microscope

- Sectioning and dissection equipment

- Partial discharge test equipment

- Gas chromatograph – Mass spectrometry

- Energy-dispersive X-ray spectroscopy

- Materials hardness mapping

- X-ray scanning and imaging

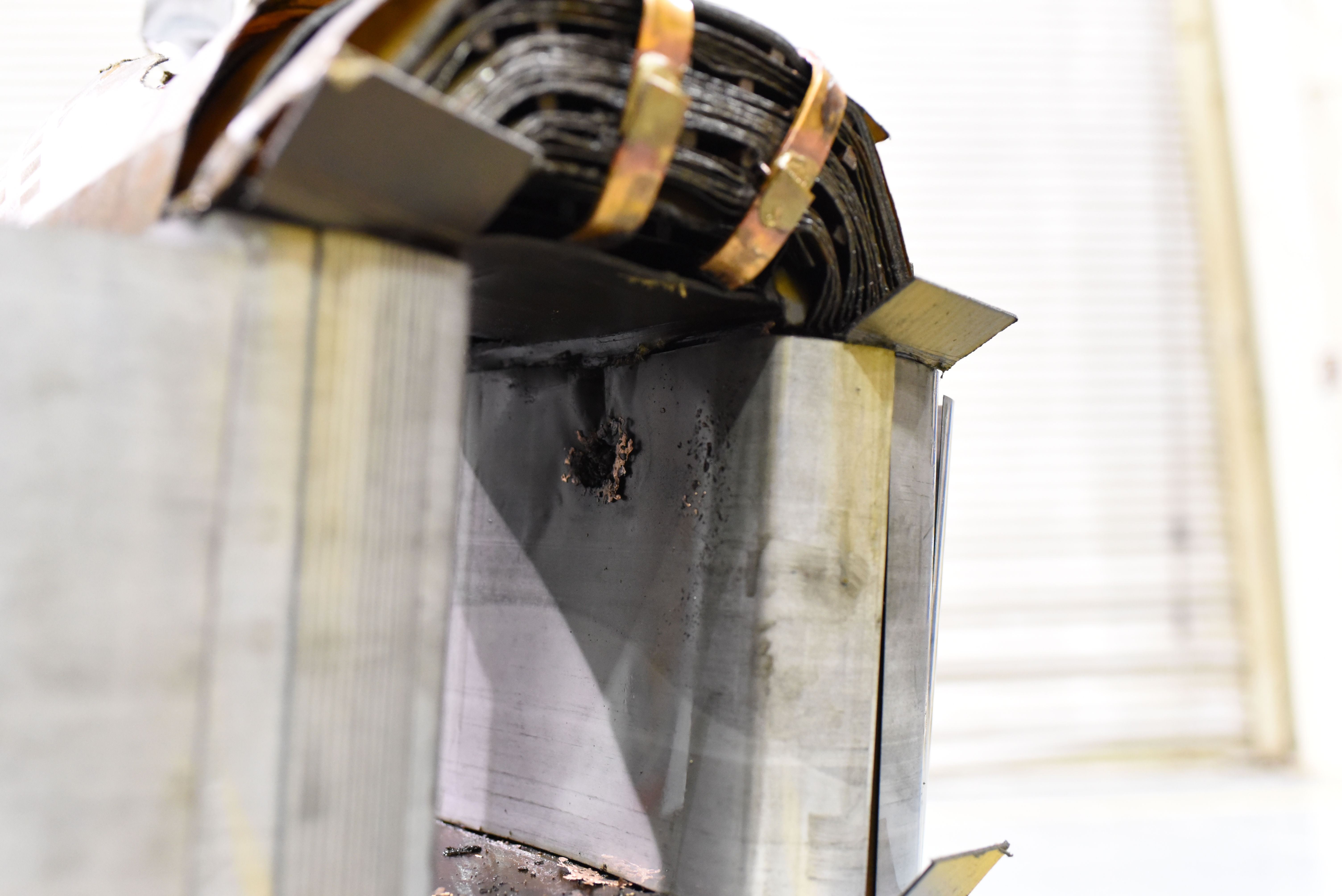

Example of a transformer that failed in-service. The failure event was detected by an online diagnostic system, but the detection could not be classified for action. The forensic analysis identified the root cause, which strengthens the future effectiveness of the online diagnostic.

Surge arresters were found to be heating in service, but the utility did not have a clear replacement criteria. The forensic analysis showed that the heating was likely due to design and material selection and that continued heating would cause further degradation. As a result, the utility had confidence to quickly remove heating arresters from service.

Distribution switches were found to be heating in the field. A forensic analysis identified corrosion at the contact points that was the cause of the localized heating. Further analysis identified a design issue as the root cause, leading to improved utility specifications to prevent this issue in the future.

Why EPRI?

The EPRI team is known for deep technical expertise that is applied to practical problems. Our engineers are passionate about understanding asset performance and failure and using those results to help improve power system performance. We take pride in high-quality results and are committed to technical excellence. EPRI has earned a reputation for objectivity, meaning that you get results that you can count on from the team that you trust.