This the multi-page printable view of this section. Click here to print.

Applications

1 - Reduce Outages by Designing Better Structures

Lab testing is a critical step to improve resiliency

One of the best ways to understand how a structure performs is to see it in action. Normally, this would require you to be in the field when a tree or branch falls on a line. EPRI’s laboratories are able to perform this test safely, repeatably, and with full data and imagery collection.

The purpose-built test site at EPRI’s High Voltage laboratory in Lenox, Massachusetts gives utility designers and engineers the ability to see their designs in action and identify opportunities to improve the design in real-time. The researchers construct full-scale structures built to your specifications, then subject the structure to the impact of a mid-span tree-strike or falling branches. Sensors and cameras capture the action so that the test team can analyze performance and identify design changes that could improve performance.

Major weather events necessitate improved resiliency and reduced restoration time. EPRI collected data to identify time consuming restoration tasks. Replacing broken poles was, by far, the most time-consuming task

Design characteristics to improve through testing

EPRI can test multiple characteristics of designs and components. Two of the main objectives of the testing are to reduce restoration time by pole saving and increasing reliability through branch deflection.

Pole Saving

EPRI’s resiliency research results have shown that a key to reducing restoration time is predictable and consistent structure performance during storms. Put simply, it is important to know the order in which components will fail, and it is important that the pole itself is not the first component on that list.

One approach is to apply the concept of mechanical coordination to your designs. Coordination is well understood in power system protection, and the same concept can apply in structure performance. Unlike protection system coordination, however, structures are made up of physical components with unknown or unpredictable performance characteristics. This makes it very difficult to model or simulate structural performance.

EPRI’s resiliency research results have shown predictable and consistent structure performance is key to reducing restoration time after storms. Put simply, it is important to know the order in which components will fail and that the pole itself is not the first component on that list.

The Test Site

Explore the test site by hovering over the green highlighted areas.

How it works

Watch a virtual tour of the test site with EPRI Project Manager Joe Potvin below.

The EPRI test site is designed with the flexibility to meet your needs. We have tested many types and sizes of structures. Call us to talk about how we test your structure!

Utilities use the full-scale test facility to assess potential resilient design improvements. The failure mode of this structure was typically a broken pole. Testing demonstrated the need for an improved design.

Branch Deflecting

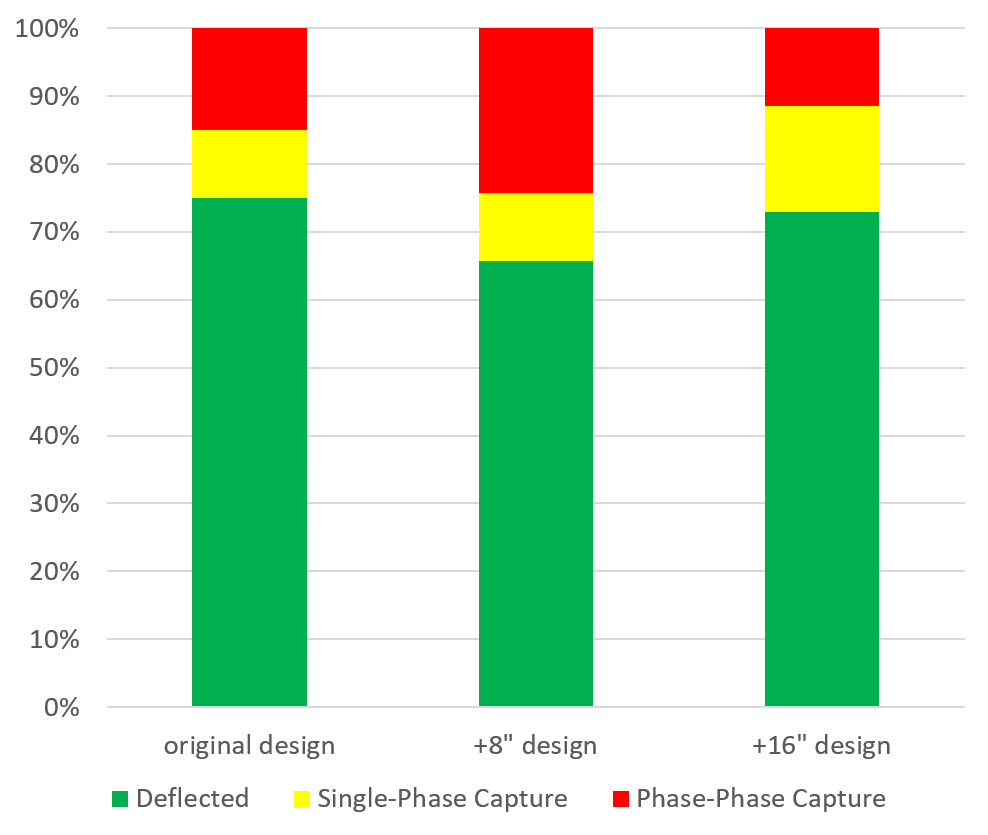

Fallen tree branches cause many outages, often by getting stuck on the line and creating an electrical fault. This test helps identify conductor configurations that are less likely to cause reliability issues when branches fall on them. Testing includes multiple combinations os configurations, as well as branch species and types that are representative of your utility’s service territory.What if we could identify conductor configurations that branches are less likely to get caught on?

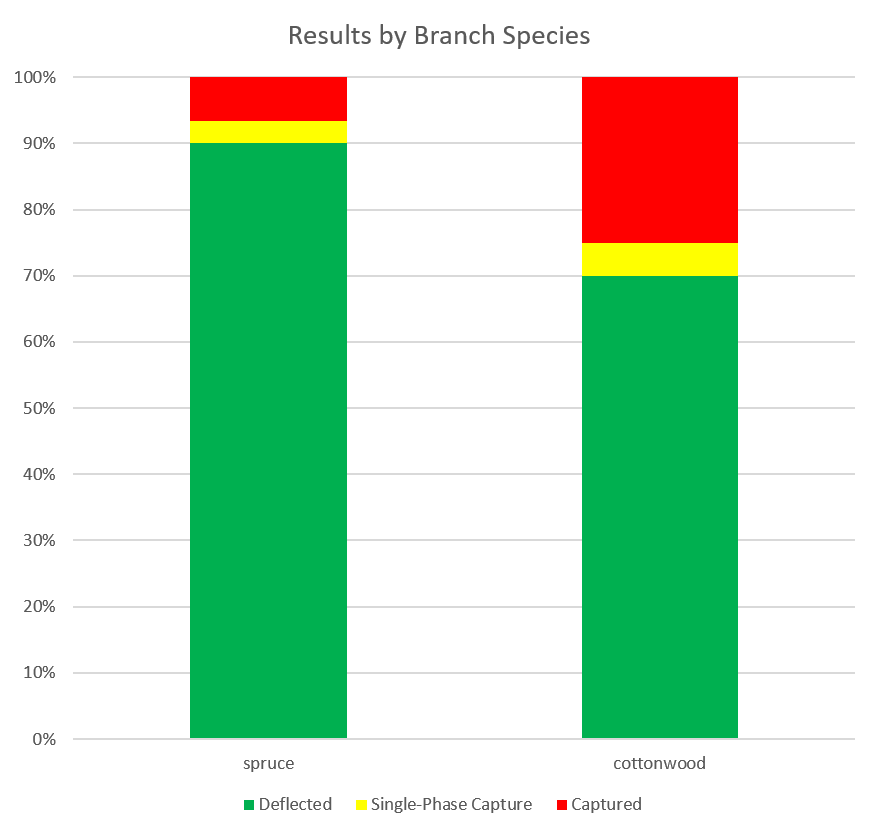

EPRI can simulate fallen branches on overhead lines by literally dropping branches from above. However, this requires careful consideration of representative tree species, review of outage data, and discussions with utility vegetation experts.

Branch deflection vs capture depends on many factors, including branch shape, line configuration, and how the branch contacts the line. The results rely on many individual tests to generate statistics.

Results can also demonstrate branch species that may be more problematic and require more management.

How to get involved

If you would like to schedule testing of your designs, please contact our research leader, Joe Potvin, at jpotvin@epri.com.

Find more information here.

2 - EPRI T&D Asset Forensics & Failure Analysis

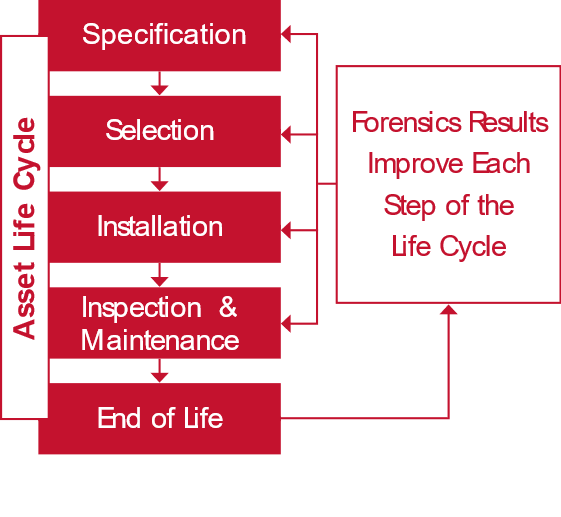

Transmission and Distribution (T&D) asset failures can significantly impact system operation, reliability, and safety. These failures are frequently difficult or impossible to predict, and they can sometimes seem random. In reality, these failures are driven by degradation mechanisms and stressors that lead to specific failure modes. Even sophisticated online monitoring data may not tell the whole story. A forensic analysis may be the best opportunity to learn why a component failed. This helps you prepare for the future by improving specifications, inspections, or maintenance practice.

Use the Past to Improve the Future

The pace of utility operations is fast – especially when you are responding to an equipment failure. By using the EPRI team to perform a forensic analysis, you not only free your team to focus on the critical work of preparing for the future, but you are also equipping them with lessons from the past. Learning from past failures gives you new insights so that you can:

- Improve specifications – Whether it is a design issue, a materials issue, or an environmental issue, there may be an opportunity to prevent future failures by updating your specifications based on causes of previous failures.

- Improve work practices – Workmanship issues during installation, operations, and maintenance are difficult to diagnose and correct without data from a forensic analysis.

- Improve inspection capabilities – A forensic analysis is a critical step in understanding how assets age and fail. This information directly informs inspection tools and practices that can improve performances.

The Forensics Process

A proper forensic analysis of a transmission or distribution component is a multi-disciplinary exercise that requires deep expertise across a broad range of engineering and material science. While each investigation is unique, EPRI applies a rigorous, scientific method that can include a multitude of approaches such as:

- Materials analysis – Even simple components can be made of complex materials with unique performance characteristics. A thorough analysis of each material not only increases understanding of the component itself, it can also expose byproducts produced during failure.

- Mechanical & Electrical Testing – Depending on the component, a series of mechanical & electrical tests can begin to identify and locate the point of failure.

- Detailed dissection – In many cases, a thorough and methodical dissection of the failed component can expose evidence of design, manufacturing, or installation errors. It takes time, dedication, and an eye for detail, but the effort is typically worthwhile.

Expertise

EPRI engineers test and analyze T&D assets every day. The team has decades of experience in understanding asset design, performance, degradation, and failure. We have experts across many assets and scientific disciplines, such as transformers, circuit breakers, connectors, corrosion, underground equipment, and distribution automation. This expertise, coupled with the EPRI labs, means that the team can perform the forensic analysis, and put the results into context to help you understand how to turn the insights into action.

Examples of T&D Asset Forensics & Failure Analysis

Tools and Capabilities

The EPRI laboratories can analyze a wide range of components and assets. We have a vast array of advanced inspection and analytical tools at our disposal, such as:

- Stereo microscope

- Scanning electron microscope

- Sectioning and dissection equipment

- Partial discharge test equipment

- Gas chromatograph – Mass spectrometry

- Energy-dispersive X-ray spectroscopy

- Materials hardness mapping

- X-ray scanning and imaging

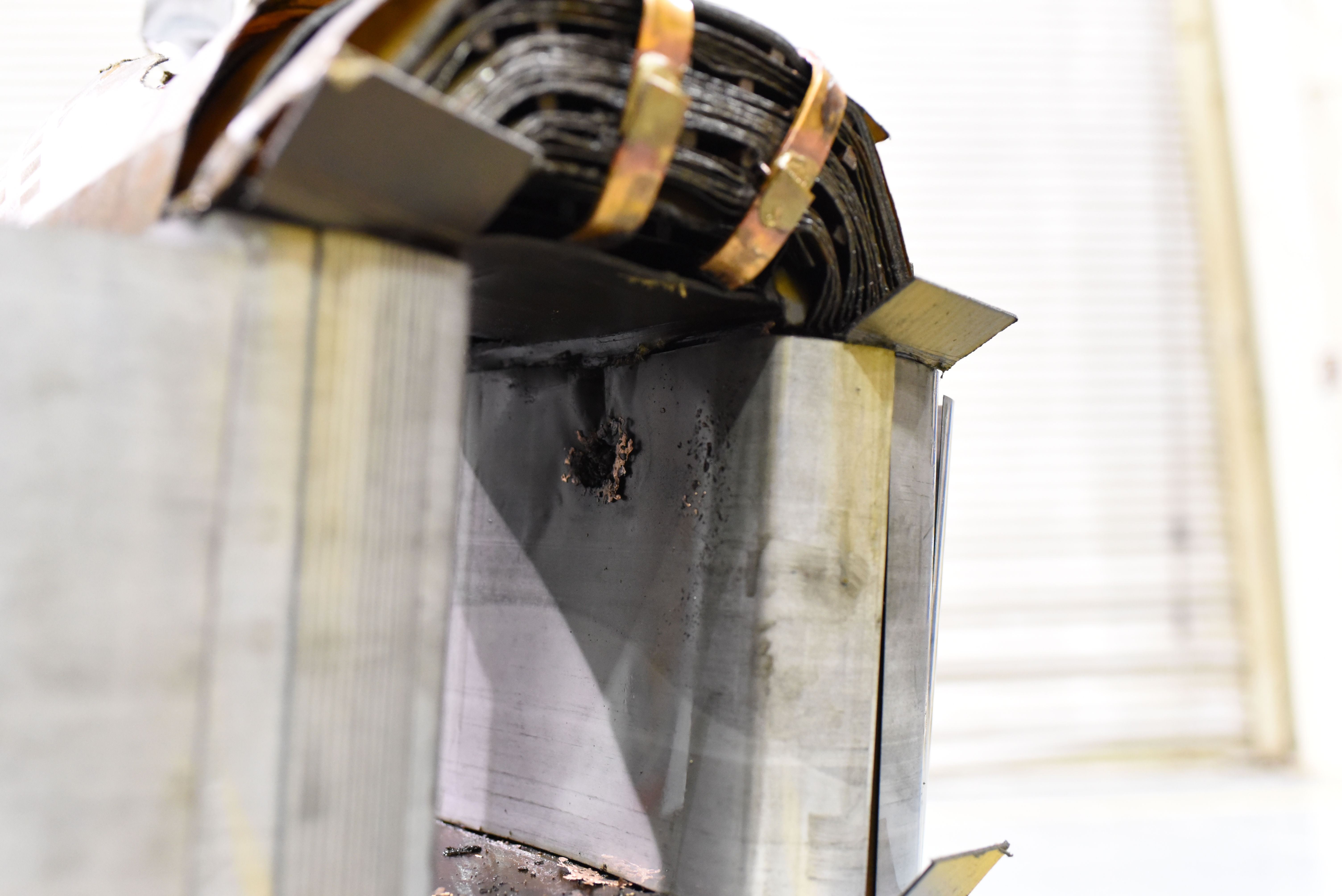

Example of a transformer that failed in-service. The failure event was detected by an online diagnostic system, but the detection could not be classified for action. The forensic analysis identified the root cause, which strengthens the future effectiveness of the online diagnostic.

Surge arresters were found to be heating in service, but the utility did not have a clear replacement criteria. The forensic analysis showed that the heating was likely due to design and material selection and that continued heating would cause further degradation. As a result, the utility had confidence to quickly remove heating arresters from service.

Distribution switches were found to be heating in the field. A forensic analysis identified corrosion at the contact points that was the cause of the localized heating. Further analysis identified a design issue as the root cause, leading to improved utility specifications to prevent this issue in the future.

Why EPRI?

The EPRI team is known for deep technical expertise that is applied to practical problems. Our engineers are passionate about understanding asset performance and failure and using those results to help improve power system performance. We take pride in high-quality results and are committed to technical excellence. EPRI has earned a reputation for objectivity, meaning that you get results that you can count on from the team that you trust.