An often-cited challenge for operators of underground systems is the loss of intuitional knowledge due to employee attrition. This challenge is particularly pronounced in urban underground and network systems, where knowledge is often held by relatively few individuals. This area of research seeks to identify, document and share institutional knowledge of underground systems through the development of references, information repositories and training. This research area includes regular updates to the EPRI Underground Distribution Systems Reference Manual (The Bronze Book) and the EPRI Underground Practices repository, a compendium of industry practices for managing underground systems.

This the multi-page printable view of this section. Click here to print.

Knowledge

- 1: Bronze Book

- 2: Utility Information Exchange

- 2.1: P180.002 Underground 2021 ARP Utility Information Exchange - June 17, 2021

- 2.2: P180.002 & P180.004 Issues with Cable Locating and Abandoning Underground Cable – Dec 10, 2021

- 2.3: P180.002 Underground Infrared Thermography Utility Information Exchange - May 18, 2022

- 2.4: P180.002 Underground Padmounted Equipment Inspection - July 28, 2022

- 2.5: P180.002 Underground Corrosion (part of Task force Meeting), May 16, 2023

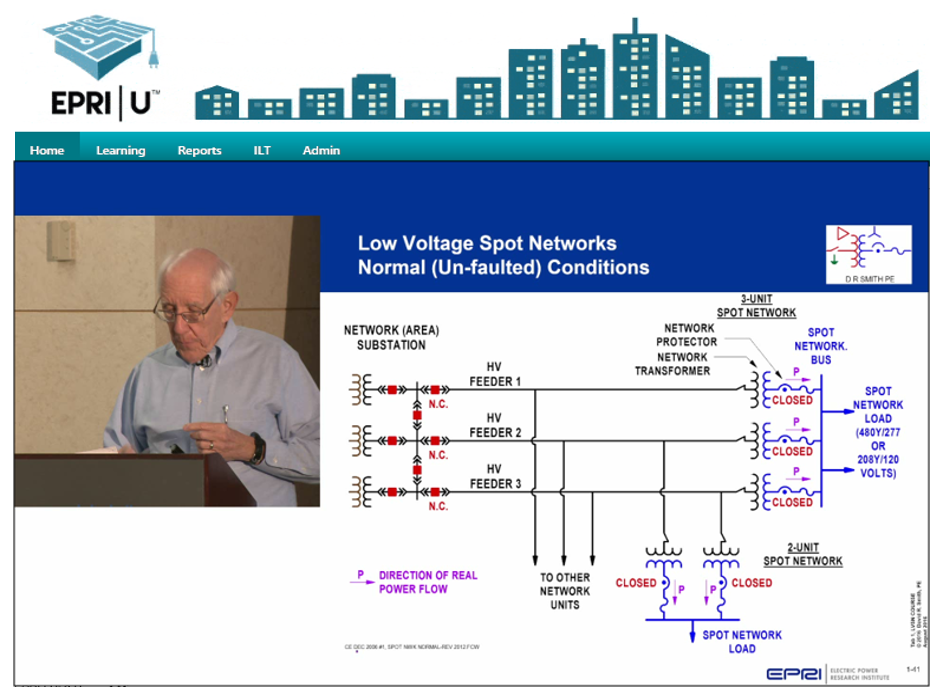

- 3: Network Training

- 4: Network Reference

- 4.1: Introduction and Overview of Secondary Network Systems

- 4.2: General Design Considerations

- 4.3: Network Substation Design

- 4.4: Primary System Grounding

- 4.5: Primary Feeder Protection

- 4.6: Network Unit Equipment

- 4.7: Backfeed Currents for Primary Feeder Faults

- 4.8: Network Overvoltages During Backfeed

- 4.9: Secondary Grid Design Considerations

- 4.10: Network Protector Relaying

- 4.11: Network System Modeling

- 4.12: 480 Volt Spot Network Protection

- 4.13: Medium Voltage Spot Network Systems

- 4.14: Closed Transition Switching and Distributed Generation

- 4.15: Measures to Reduce Arc-Flash Hazards in 480-Volt Spot Networks

- 4.16: Special System Events

- 4.17: Appendix 1

- 4.18: Appendix 2

- 4.19: Appendix 3

- 4.20: Appendix 4

- 4.21: Appendix 5

- 5: Interest Groups

- 6: Apps for Low-Voltage Network Scenarios

- 6.1: Background on Network-Protector Relaying

- 6.2: Network Backfeeds for an Open Feeder

- 6.3: Network-Protector Operations with a Primary-Side Blown Fuse

- 6.4: Crossed or Rolled Phases on the Primary

- 7: Underground Practices Repository

- 7.1: About the Repository

- 7.2: Company Summaries

- 7.2.1: AEP - Ohio

- 7.2.2: Ameren Missouri

- 7.2.3: BC Hydro

- 7.2.4: CEI - The Illuminating Company

- 7.2.5: CenterPoint Energy

- 7.2.6: Central Hudson Gas & Electric

- 7.2.7: Con Edison - Consolidated Edison

- 7.2.8: Duke Energy Florida

- 7.2.9: Duke Energy Ohio

- 7.2.10: Energex

- 7.2.11: ESB Networks

- 7.2.12: Georgia Power

- 7.2.13: HECO - The Hawaiian Electric Company

- 7.2.14: National Grid (Albany)

- 7.2.15: PG&E

- 7.2.16: Portland General Electric

- 7.2.17: SCL - Seattle City Light

- 7.2.18: Tampa Electric

- 7.3: Construction

- 7.3.1: Account Management-Scheduling

- 7.3.1.1: Portland General Electric

- 7.3.2: Cable Installation and Replacement

- 7.3.2.1: AEP - Ohio

- 7.3.2.2: Duke Energy Florida

- 7.3.2.3: ESB Networks

- 7.3.2.4: Georgia Power

- 7.3.2.5: Portland General Electric

- 7.3.2.6: References

- 7.3.3: Cable Pulling

- 7.3.3.1: Ameren Missouri

- 7.3.3.2: CEI - The Illuminating Company

- 7.3.3.3: CenterPoint Energy

- 7.3.3.4: Con Edison - Consolidated Edison

- 7.3.3.5: Duke Energy Florida

- 7.3.3.6: Duke Energy Ohio

- 7.3.3.7: Energex

- 7.3.3.8: ESB Networks

- 7.3.3.9: Georgia Power

- 7.3.3.10: HECO - The Hawaiian Electric Company

- 7.3.3.11: National Grid

- 7.3.3.12: PG&E

- 7.3.3.13: Portland General Electric

- 7.3.3.14: SCL - Seattle City Light

- 7.3.3.15: References

- 7.3.4: Cable Quality Control

- 7.3.4.1: AEP - Ohio

- 7.3.4.2: Ameren Missouri

- 7.3.4.3: CenterPoint Energy

- 7.3.4.4: Con Edison - Consolidated Edison

- 7.3.4.5: Duke Energy Florida

- 7.3.4.6: Duke Energy Ohio

- 7.3.4.7: Energex

- 7.3.4.8: ESB Networks

- 7.3.4.9: Georgia Power

- 7.3.4.10: National Grid

- 7.3.4.11: PG&E

- 7.3.4.12: SCL - Seattle City Light

- 7.3.4.13: Survey Results

- 7.3.5: Civil Construction

- 7.3.5.1: AEP - Ohio

- 7.3.5.2: Ameren Missouri

- 7.3.5.3: CEI - The Illuminating Company

- 7.3.5.4: CenterPoint Energy

- 7.3.5.5: Con Edison - Consolidated Edison

- 7.3.5.6: Duke Energy Florida

- 7.3.5.7: Duke Energy Ohio

- 7.3.5.8: Energex

- 7.3.5.9: ESB Networks

- 7.3.5.10: Georgia Power

- 7.3.5.11: HECO - The Hawaiian Electric Company

- 7.3.5.12: National Grid

- 7.3.5.13: PG&E

- 7.3.5.14: SCL - Seattle City Light

- 7.3.5.15: Survey Results

- 7.3.6: Contracting

- 7.3.6.1: AEP - Ohio

- 7.3.6.2: Ameren Missouri

- 7.3.6.3: CEI - The Illuminating Company

- 7.3.6.4: CenterPoint Energy

- 7.3.6.5: Con Edison - Consolidated Edison

- 7.3.6.6: Duke Energy Florida

- 7.3.6.7: Duke Energy Ohio

- 7.3.6.8: Georgia Power

- 7.3.6.9: HECO - The Hawaiian Electric Company

- 7.3.6.10: National Grid

- 7.3.6.11: PG&E

- 7.3.6.12: Portland General Electric

- 7.3.6.13: SCL - Seattle City Light

- 7.3.6.14: Survey Results

- 7.3.7: Crew Makeup - Job Progression

- 7.3.7.1: AEP - Ohio

- 7.3.7.2: Ameren Missouri

- 7.3.7.3: CEI - The Illuminating Company

- 7.3.7.4: CenterPoint Energy

- 7.3.7.5: Con Edison - Consolidated Edison

- 7.3.7.6: Duke Energy Florida

- 7.3.7.7: Duke Energy Ohio

- 7.3.7.8: Energex

- 7.3.7.9: ESB Networks

- 7.3.7.10: Georgia Power

- 7.3.7.11: HECO - The Hawaiian Electric Company

- 7.3.7.12: National Grid

- 7.3.7.13: PG&E

- 7.3.7.14: Portland General Electric

- 7.3.7.15: SCL - Seattle City Light

- 7.3.7.16: Practices Comparison

- 7.3.7.17: Survey Results

- 7.3.8: Field IT Technology/Training

- 7.3.8.1: Portland General Electric

- 7.3.9: Manholes

- 7.3.9.1: Ameren Missouri

- 7.3.9.2: Duke Energy Florida

- 7.3.9.3: Georgia Power

- 7.3.9.4: Portland General Electric

- 7.3.9.5: Survey Results

- 7.3.10: Master Reel

- 7.3.10.1: CenterPoint Energy

- 7.3.11: Material Failure Reporting System

- 7.3.11.1: AEP - Ohio

- 7.3.11.2: Ameren Missouri

- 7.3.11.3: CEI - The Illuminating Company

- 7.3.11.4: CenterPoint Energy

- 7.3.11.5: Con Edison - Consolidated Edison

- 7.3.11.6: Duke Energy Florida

- 7.3.11.7: Duke Energy Ohio

- 7.3.11.8: Energex

- 7.3.11.9: ESB Networks

- 7.3.11.10: Georgia Power

- 7.3.11.11: National Grid

- 7.3.11.12: PG&E

- 7.3.11.13: Portland General Electric

- 7.3.11.14: Survey Results

- 7.3.12: Organization

- 7.3.12.1: AEP - Ohio

- 7.3.12.2: Ameren Missouri

- 7.3.12.3: CEI - The Illuminating Company

- 7.3.12.4: CenterPoint Energy

- 7.3.12.5: Con Edison - Consolidated Edison

- 7.3.12.6: Duke Energy Florida

- 7.3.12.7: Duke Energy Ohio

- 7.3.12.8: Energex

- 7.3.12.9: ESB Networks

- 7.3.12.10: Georgia Power

- 7.3.12.11: HECO - The Hawaiian Electric Company

- 7.3.12.12: National Grid

- 7.3.12.13: PG&E

- 7.3.12.14: Portland General Electric

- 7.3.12.15: SCL - Seattle City Light

- 7.3.12.16: Survey Results

- 7.3.13: Pre-cast Concrete Conduits

- 7.3.13.1: CEI - The Illuminating Company

- 7.3.13.2: Con Edison - Consolidated Edison

- 7.3.13.3: Duke Energy Ohio

- 7.3.14: Project Management

- 7.3.14.1: AEP - Ohio

- 7.3.14.2: Ameren Missouri

- 7.3.14.3: CEI - The Illuminating Company

- 7.3.14.4: CenterPoint Energy

- 7.3.14.5: Con Edison - Consolidated Edison

- 7.3.14.6: Duke Energy Florida

- 7.3.14.7: Duke Energy Ohio

- 7.3.14.8: Energex

- 7.3.14.9: ESB Networks

- 7.3.14.10: Georgia Power

- 7.3.14.11: HECO - The Hawaiian Electric Company

- 7.3.14.12: National Grid

- 7.3.14.13: PG&E

- 7.3.14.14: Portland General Electric

- 7.3.14.15: SCL - Seattle City Light

- 7.3.14.16: Survey Results

- 7.3.15: Separable Connector Installation

- 7.3.15.1: Duke Energy Florida

- 7.3.15.2: HECO - The Hawaiian Electric Company

- 7.3.15.3: Survey Results

- 7.3.16: Splicing

- 7.3.16.1: AEP - Ohio

- 7.3.16.2: Ameren Missouri

- 7.3.16.3: CEI - The Illuminating Company

- 7.3.16.4: CenterPoint Energy

- 7.3.16.5: Con Edison - Consolidated Edison

- 7.3.16.6: Duke Energy Florida

- 7.3.16.7: Duke Energy Ohio

- 7.3.16.8: Energex

- 7.3.16.9: ESB Networks

- 7.3.16.10: Georgia Power

- 7.3.16.11: HECO - The Hawaiian Electric Company

- 7.3.16.12: National Grid

- 7.3.16.13: PG&E

- 7.3.16.14: Portland General Electric

- 7.3.16.15: SCL - Seattle City Light

- 7.3.16.16: References

- 7.3.16.17: Survey Results

- 7.3.17: Three Phase Pad Mounted Transformer Installation

- 7.3.17.1: CenterPoint Energy

- 7.3.18: Training Facility

- 7.3.18.1: Portland General Electric

- 7.3.19: Resource Management

- 7.3.19.1: Portland General Electric

- 7.3.20: Vault Grounding

- 7.3.20.1: AEP - Ohio

- 7.3.20.2: Ameren Missouri

- 7.3.20.3: CEI - The Illuminating Company

- 7.3.20.4: CenterPoint Energy

- 7.3.20.5: Duke Energy Florida

- 7.3.20.6: Duke Energy Ohio

- 7.3.20.7: National Grid

- 7.3.20.8: PG&E

- 7.3.20.9: Portland General Electric

- 7.3.20.10: SCL - Seattle City Light

- 7.3.20.11: Survey Results

- 7.4: Design

- 7.4.1: Cable Design

- 7.4.1.1: AEP - Ohio

- 7.4.1.2: Ameren Missouri

- 7.4.1.3: CEI - The Illuminating Company

- 7.4.1.4: CenterPoint Energy

- 7.4.1.5: Con Edison - Consolidated Edison

- 7.4.1.6: Duke Energy Florida

- 7.4.1.7: Duke Energy Ohio

- 7.4.1.8: Energex

- 7.4.1.9: ESB Networks

- 7.4.1.10: Georgia Power

- 7.4.1.11: HECO - The Hawaiian Electric Company

- 7.4.1.12: National Grid

- 7.4.1.13: PG&E

- 7.4.1.14: Portland General Electric

- 7.4.1.15: SCL - Seattle City Light

- 7.4.1.16: References

- 7.4.1.17: Survey Results

- 7.4.2: Cable Limiter Application

- 7.4.2.1: AEP - Ohio

- 7.4.2.2: Ameren Missouri

- 7.4.2.3: CEI - The Illuminating Company

- 7.4.2.4: CenterPoint Energy

- 7.4.2.5: Con Edison - Consolidated Edison

- 7.4.2.6: Duke Energy Florida

- 7.4.2.7: Duke Energy Ohio

- 7.4.2.8: Georgia Power

- 7.4.2.9: HECO - The Hawaiian Electric Company

- 7.4.2.10: National Grid

- 7.4.2.11: PG&E

- 7.4.2.12: Portland General Electric

- 7.4.2.13: SCL - Seattle City Light

- 7.4.2.14: Practices Comparison

- 7.4.2.15: References

- 7.4.2.16: Survey Results

- 7.4.3: Civil Design

- 7.4.3.1: Duke Energy Florida

- 7.4.3.2: Energex

- 7.4.3.3: ESB Networks

- 7.4.3.4: Georgia Power

- 7.4.3.5: References

- 7.4.4: Key Accounts

- 7.4.4.1: AEP - Ohio

- 7.4.4.2: Ameren Missouri

- 7.4.4.3: CenterPoint Energy

- 7.4.4.4: Con Edison - Consolidated Edison

- 7.4.4.5: Duke Energy Florida

- 7.4.4.6: Duke Energy Ohio

- 7.4.4.7: Energex

- 7.4.4.8: ESB Networks

- 7.4.4.9: Georgia Power

- 7.4.4.10: HECO - The Hawaiian Electric Company

- 7.4.4.11: National Grid

- 7.4.4.12: PG&E

- 7.4.4.13: Portland General Electric

- 7.4.4.14: SCL - Seattle City Light

- 7.4.5: Mapping - Recording “As-Builts”

- 7.4.5.1: AEP - Ohio

- 7.4.5.2: Ameren Missouri

- 7.4.5.3: CEI - The Illuminating Company

- 7.4.5.4: CenterPoint Energy

- 7.4.5.5: Con Edison - Consolidated Edison

- 7.4.5.6: Duke Energy Florida

- 7.4.5.7: Duke Energy Ohio

- 7.4.5.8: Energex

- 7.4.5.9: ESB Networks

- 7.4.5.10: Georgia Power

- 7.4.5.11: HECO - The Hawaiian Electric Company

- 7.4.5.12: National Grid

- 7.4.5.13: PG&E

- 7.4.5.14: Portland General Electric

- 7.4.5.15: SCL - Seattle City Light

- 7.4.6: Network Area Substation Design

- 7.4.6.1: AEP - Ohio

- 7.4.6.2: Ameren Missouri

- 7.4.6.3: CEI - The Illuminating Company

- 7.4.6.4: CenterPoint Energy

- 7.4.6.5: Con Edison - Consolidated Edison

- 7.4.6.6: Duke Energy Florida

- 7.4.6.7: Duke Energy Ohio

- 7.4.6.8: Energex

- 7.4.6.9: ESB Networks

- 7.4.6.10: Georgia Power

- 7.4.6.11: HECO - The Hawaiian Electric Company

- 7.4.6.12: National Grid

- 7.4.6.13: PG&E

- 7.4.6.14: SCL - Seattle City Light

- 7.4.6.15: References

- 7.4.7: Network Design

- 7.4.7.1: AEP - Ohio

- 7.4.7.2: Ameren Missouri

- 7.4.7.3: CEI - The Illuminating Company

- 7.4.7.4: CenterPoint Energy

- 7.4.7.5: Con Edison - Consolidated Edison

- 7.4.7.6: Duke Energy Florida

- 7.4.7.7: Duke Energy Ohio

- 7.4.7.8: Energex

- 7.4.7.9: ESB Networks

- 7.4.7.10: Georgia Power

- 7.4.7.11: HECO - The Hawaiian Electric Company

- 7.4.7.12: National Grid

- 7.4.7.13: PG&E

- 7.4.7.14: Portland General Electric

- 7.4.7.15: SCL - Seattle City Light

- 7.4.7.16: References

- 7.4.7.17: Survey Results

- 7.4.8: Network Protector Design

- 7.4.8.1: AEP - Ohio

- 7.4.8.2: Ameren Missouri

- 7.4.8.3: CEI - The Illuminating Company

- 7.4.8.4: CenterPoint Energy

- 7.4.8.5: Con Edison - Consolidated Edison

- 7.4.8.6: Duke Energy Florida

- 7.4.8.7: Duke Energy Ohio

- 7.4.8.8: Energex

- 7.4.8.9: ESB Networks

- 7.4.8.10: Georgia Power

- 7.4.8.11: HECO - The Hawaiian Electric Company

- 7.4.8.12: National Grid

- 7.4.8.13: PG&E

- 7.4.8.14: SCL - Seattle City Light

- 7.4.8.15: References

- 7.4.9: Network Rehabilitation

- 7.4.9.1: AEP - Ohio

- 7.4.9.2: Ameren Missouri

- 7.4.9.3: Duke Energy Florida

- 7.4.9.4: Duke Energy Ohio

- 7.4.9.5: Energex

- 7.4.9.6: Georgia Power

- 7.4.9.7: PG&E

- 7.4.9.8: References

- 7.4.9.9: Survey Results

- 7.4.10: Network Reliability

- 7.4.10.1: Con Edison - Consolidated Edison

- 7.4.10.2: HECO - The Hawaiian Electric Company

- 7.4.10.3: AEP - Ohio

- 7.4.10.4: Ameren Missouri

- 7.4.10.5: CEI - The Illuminating Company

- 7.4.10.6: Duke Energy Florida

- 7.4.10.7: Duke Energy Ohio

- 7.4.10.8: Energex

- 7.4.10.9: ESB Networks

- 7.4.10.10: Georgia Power

- 7.4.10.11: National Grid

- 7.4.10.12: PG&E

- 7.4.10.13: Survey Results

- 7.4.11: Network Transformer Design

- 7.4.11.1: AEP - Ohio

- 7.4.11.2: Ameren Missouri

- 7.4.11.3: CEI - The Illuminating Company

- 7.4.11.4: CenterPoint Energy

- 7.4.11.5: Con Edison - Consolidated Edison

- 7.4.11.6: Duke Energy Florida

- 7.4.11.7: Duke Energy Ohio

- 7.4.11.8: Georgia Power

- 7.4.11.9: HECO - The Hawaiian Electric Company

- 7.4.11.10: National Grid

- 7.4.11.11: PG&E

- 7.4.11.12: SCL - Seattle City Light

- 7.4.11.13: Practices Comparison

- 7.4.11.14: References

- 7.4.11.15: Survey Results

- 7.4.12: Network Transformers—Primary Switch

- 7.4.12.1: AEP - Ohio

- 7.4.12.2: Ameren Missouri

- 7.4.12.3: CEI - The Illuminating Company

- 7.4.12.4: CenterPoint Energy

- 7.4.12.5: Con Edison - Consolidated Edison

- 7.4.12.6: Duke Energy Florida

- 7.4.12.7: Duke Energy Ohio

- 7.4.12.8: Energex

- 7.4.12.9: ESB Networks

- 7.4.12.10: Georgia Power

- 7.4.12.11: HECO - The Hawaiian Electric Company

- 7.4.12.12: National Grid

- 7.4.12.13: PG&E

- 7.4.12.14: SCL - Seattle City Light

- 7.4.12.15: Practices Comparison

- 7.4.12.16: References

- 7.4.12.17: Survey Results

- 7.4.13: Network Unit Design

- 7.4.13.1: AEP - Ohio

- 7.4.13.2: Ameren Missouri

- 7.4.13.3: CenterPoint Energy

- 7.4.13.4: Duke Energy Florida

- 7.4.13.5: Duke Energy Ohio

- 7.4.13.6: Georgia Power

- 7.4.13.7: National Grid

- 7.4.13.8: PG&E

- 7.4.13.9: Portland General Electric

- 7.4.13.10: References

- 7.4.14: New Service Design

- 7.4.14.1: Ameren Missouri

- 7.4.14.2: CEI - The Illuminating Company

- 7.4.14.3: CenterPoint Energy

- 7.4.14.4: Con Edison - Consolidated Edison

- 7.4.14.5: Duke Energy Florida

- 7.4.14.6: Duke Energy Ohio

- 7.4.14.7: Energex

- 7.4.14.8: ESB Networks

- 7.4.14.9: HECO - The Hawaiian Electric Company

- 7.4.14.10: National Grid

- 7.4.14.11: PG&E

- 7.4.14.12: SCL - Seattle City Light

- 7.4.15: Non-Network Design

- 7.4.15.1: Ameren Missouri

- 7.4.15.2: CEI - The Illuminating Company

- 7.4.15.3: CenterPoint Energy

- 7.4.15.4: Duke Energy Florida

- 7.4.15.5: Duke Energy Ohio

- 7.4.15.6: Energex

- 7.4.15.7: ESB Networks

- 7.4.15.8: Georgia Power

- 7.4.15.9: HECO - The Hawaiian Electric Company

- 7.4.15.10: National Grid

- 7.4.15.11: PG&E

- 7.4.15.12: Survey Results

- 7.4.16: Non-Network Service

- 7.4.16.1: Ameren Missouri

- 7.4.16.2: CEI - The Illuminating Company

- 7.4.16.3: CenterPoint Energy

- 7.4.16.4: Duke Energy Florida

- 7.4.16.5: HECO - The Hawaiian Electric Company

- 7.4.16.6: PG&E

- 7.4.17: Organization

- 7.4.17.1: AEP - Ohio

- 7.4.17.2: Ameren Missouri

- 7.4.17.3: CEI - The Illuminating Company

- 7.4.17.4: CenterPoint Energy

- 7.4.17.5: Con Edison - Consolidated Edison

- 7.4.17.6: Duke Energy Florida

- 7.4.17.7: Duke Energy Ohio

- 7.4.17.8: Energex

- 7.4.17.9: ESB Networks

- 7.4.17.10: Georgia Power

- 7.4.17.11: HECO - The Hawaiian Electric Company

- 7.4.17.12: National Grid

- 7.4.17.13: PG&E

- 7.4.17.14: Portland General Electric

- 7.4.17.15: SCL - Seattle City Light

- 7.4.17.16: Survey Results

- 7.4.18: Power Quality

- 7.4.18.1: AEP - Ohio

- 7.4.18.2: Ameren Missouri

- 7.4.18.3: CEI - The Illuminating Company

- 7.4.18.4: CenterPoint Energy

- 7.4.18.5: Con Edison - Consolidated Edison

- 7.4.18.6: Duke Energy Florida

- 7.4.18.7: Duke Energy Ohio

- 7.4.18.8: Energex

- 7.4.18.9: ESB Networks

- 7.4.18.10: Georgia Power

- 7.4.18.11: PG&E

- 7.4.18.12: Portland General Electric

- 7.4.18.13: SCL - Seattle City Light

- 7.4.19: Spot Network Design

- 7.4.19.1: AEP - Ohio

- 7.4.19.2: Ameren Missouri

- 7.4.19.3: CEI - The Illuminating Company

- 7.4.19.4: CenterPoint Energy

- 7.4.19.5: Con Edison - Consolidated Edison

- 7.4.19.6: Duke Energy Florida

- 7.4.19.7: Duke Energy Ohio

- 7.4.19.8: Georgia Power

- 7.4.19.9: HECO - The Hawaiian Electric Company

- 7.4.19.10: National Grid

- 7.4.19.11: PG&E

- 7.4.19.12: SCL - Seattle City Light

- 7.4.19.13: References

- 7.4.19.14: Survey Results

- 7.4.20: Standards

- 7.4.20.1: AEP - Ohio

- 7.4.20.2: Ameren Missouri

- 7.4.20.3: CEI - The Illuminating Company

- 7.4.20.4: CenterPoint Energy

- 7.4.20.5: Con Edison - Consolidated Edison

- 7.4.20.6: Duke Energy Florida

- 7.4.20.7: Duke Energy Ohio

- 7.4.20.8: Energex

- 7.4.20.9: ESB Networks

- 7.4.20.10: Georgia Power

- 7.4.20.11: HECO - The Hawaiian Electric Company

- 7.4.20.12: National Grid

- 7.4.20.13: PG&E

- 7.4.20.14: Portland General Electric

- 7.4.20.15: SCL - Seattle City Light

- 7.4.20.16: Survey Results

- 7.4.21: System Hardening

- 7.4.21.1: CenterPoint Energy

- 7.4.21.2: Con Edison - Consolidated Edison

- 7.4.21.3: Duke Energy Florida

- 7.4.21.4: Energex

- 7.4.21.5: Georgia Power

- 7.4.21.6: PG&E

- 7.4.21.7: Survey Results

- 7.4.22: Three Phase Loops

- 7.4.22.1: CenterPoint Energy

- 7.4.23: Vault - Manhole Design

- 7.4.23.1: AEP - Ohio

- 7.4.23.2: Ameren Missouri

- 7.4.23.3: CEI - The Illuminating Company

- 7.4.23.4: CenterPoint Energy

- 7.4.23.5: Con Edison - Consolidated Edison

- 7.4.23.6: Duke Energy Florida

- 7.4.23.7: Duke Energy Ohio

- 7.4.23.8: Energex

- 7.4.23.9: ESB Networks

- 7.4.23.10: Georgia Power

- 7.4.23.11: HECO - The Hawaiian Electric Company

- 7.4.23.12: National Grid

- 7.4.23.13: PG&E

- 7.4.23.14: Portland General Electric

- 7.4.23.15: SCL - Seattle City Light

- 7.4.23.16: References

- 7.4.23.17: Survey Results

- 7.4.24: Vault Design – Remote Trip Panel

- 7.4.24.1: CenterPoint Energy

- 7.5: Maintenance

- 7.5.1: Cable Testing - Diagnostics

- 7.5.1.1: AEP - Ohio

- 7.5.1.2: Ameren Missouri

- 7.5.1.3: CEI - The Illuminating Company

- 7.5.1.4: CenterPoint Energy

- 7.5.1.5: Con Edison - Consolidated Edison

- 7.5.1.6: Duke Energy Florida

- 7.5.1.7: Duke Energy Ohio

- 7.5.1.8: Energex

- 7.5.1.9: ESB Networks

- 7.5.1.10: Georgia Power

- 7.5.1.11: HECO - The Hawaiian Electric Company

- 7.5.1.12: National Grid

- 7.5.1.13: PG&E

- 7.5.1.14: Portland General Electric

- 7.5.1.15: SCL - Seattle City Light

- 7.5.1.16: Practices Comparison

- 7.5.1.17: References

- 7.5.1.18: Survey Results

- 7.5.2: Civil Maintenance

- 7.5.2.1: AEP - Ohio

- 7.5.2.2: Ameren Missouri

- 7.5.2.3: CEI - The Illuminating Company

- 7.5.2.4: CenterPoint Energy

- 7.5.2.5: Con Edison - Consolidated Edison

- 7.5.2.6: Duke Energy Florida

- 7.5.2.7: Duke Energy Ohio

- 7.5.2.8: Energex

- 7.5.2.9: ESB Networks

- 7.5.2.10: Georgia Power

- 7.5.2.11: HECO - The Hawaiian Electric Company

- 7.5.2.12: National Grid

- 7.5.2.13: PG&E

- 7.5.2.14: Portland General Electric

- 7.5.2.15: SCL - Seattle City Light

- 7.5.3: Elevated Voltage Testing (Stray Voltage)

- 7.5.3.1: Con Edison - Consolidated Edison

- 7.5.3.2: National Grid

- 7.5.3.3: Energex

- 7.5.4: Failure Analysis

- 7.5.4.1: AEP - Ohio

- 7.5.4.2: Ameren Missouri

- 7.5.4.3: CEI - The Illuminating Company

- 7.5.4.4: CenterPoint Energy

- 7.5.4.5: Con Edison - Consolidated Edison

- 7.5.4.6: Duke Energy Florida

- 7.5.4.7: Duke Energy Ohio

- 7.5.4.8: Energex

- 7.5.4.9: ESB Networks

- 7.5.4.10: Georgia Power

- 7.5.4.11: HECO - The Hawaiian Electric Company

- 7.5.4.12: National Grid

- 7.5.4.13: PG&E

- 7.5.4.14: Portland General Electric

- 7.5.4.15: SCL - Seattle City Light

- 7.5.4.16: Survey Results

- 7.5.5: Hot Phasing

- 7.5.5.1: CEI - The Illuminating Company

- 7.5.6: Manhole Inspection - Maintenance

- 7.5.6.1: AEP - Ohio

- 7.5.6.2: Ameren Missouri

- 7.5.6.3: CEI - The Illuminating Company

- 7.5.6.4: CenterPoint Energy

- 7.5.6.5: Con Edison - Consolidated Edison

- 7.5.6.6: Duke Energy Florida

- 7.5.6.7: Duke Energy Ohio

- 7.5.6.8: Energex

- 7.5.6.9: ESB Networks

- 7.5.6.10: Georgia Power

- 7.5.6.11: HECO - The Hawaiian Electric Company

- 7.5.6.12: National Grid

- 7.5.6.13: PG&E

- 7.5.6.14: Portland General Electric

- 7.5.6.15: SCL - Seattle City Light

- 7.5.6.16: Survey Results

- 7.5.7: Network Protector Maintenance

- 7.5.7.1: AEP - Ohio

- 7.5.7.2: Ameren Missouri

- 7.5.7.3: CEI - The Illuminating Company

- 7.5.7.4: CenterPoint Energy

- 7.5.7.5: Con Edison - Consolidated Edison

- 7.5.7.6: Duke Energy Florida

- 7.5.7.7: Duke Energy Ohio

- 7.5.7.8: Georgia Power

- 7.5.7.9: HECO - The Hawaiian Electric Company

- 7.5.7.10: National Grid

- 7.5.7.11: PG&E

- 7.5.7.12: Portland General Electric

- 7.5.7.13: SCL - Seattle City Light

- 7.5.7.14: Practices Comparison

- 7.5.7.15: References

- 7.5.7.16: Survey Results

- 7.5.8: Network Protector Operational Test

- 7.5.8.1: AEP - Ohio

- 7.5.8.2: Ameren Missouri

- 7.5.8.3: CEI - The Illuminating Company

- 7.5.8.4: CenterPoint Energy

- 7.5.8.5: Con Edison - Consolidated Edison

- 7.5.8.6: Duke Energy Florida

- 7.5.8.7: Duke Energy Ohio

- 7.5.8.8: Georgia Power

- 7.5.8.9: National Grid

- 7.5.8.10: PG&E

- 7.5.8.11: Portland General Electric

- 7.5.8.12: SCL - Seattle City Light

- 7.5.8.13: Survey Results

- 7.5.9: Network Transformer Maintenance

- 7.5.9.1: AEP - Ohio

- 7.5.9.2: Ameren Missouri

- 7.5.9.3: CEI - The Illuminating Company

- 7.5.9.4: CenterPoint Energy

- 7.5.9.5: Con Edison - Consolidated Edison

- 7.5.9.6: Duke Energy Florida

- 7.5.9.7: Duke Energy Ohio

- 7.5.9.8: Energex

- 7.5.9.9: ESB Networks

- 7.5.9.10: Georgia Power

- 7.5.9.11: HECO - The Hawaiian Electric Company

- 7.5.9.12: National Grid

- 7.5.9.13: PG&E

- 7.5.9.14: Portland General Electric

- 7.5.9.15: SCL - Seattle City Light

- 7.5.9.16: Practices Comparison

- 7.5.9.17: References

- 7.5.9.18: Survey Results

- 7.5.10: Network Transformer Replacement Criteria

- 7.5.10.1: Ameren Missouri

- 7.5.10.2: Duke Energy Florida

- 7.5.10.3: Energex

- 7.5.10.4: ESB Networks

- 7.5.10.5: Survey Results

- 7.5.11: Network Vault Inspection - Maintenance

- 7.5.11.1: AEP - Ohio

- 7.5.11.2: Ameren Missouri

- 7.5.11.3: CEI - The Illuminating Company

- 7.5.11.4: CenterPoint Energy

- 7.5.11.5: Con Edison - Consolidated Edison

- 7.5.11.6: Duke Energy Florida

- 7.5.11.7: Duke Energy Ohio

- 7.5.11.8: Georgia Power

- 7.5.11.9: HECO - The Hawaiian Electric Company

- 7.5.11.10: National Grid

- 7.5.11.11: PG&E

- 7.5.11.12: Portland General Electric

- 7.5.11.13: SCL - Seattle City Light

- 7.5.12: Non-Network Vault Inspection - Maintenance

- 7.5.12.1: HECO - The Hawaiian Electric Company

- 7.5.12.2: CEI - The Illuminating Company

- 7.5.12.3: CenterPoint Energy

- 7.5.12.4: Duke Energy Florida

- 7.5.12.5: Energex

- 7.5.12.6: ESB Networks

- 7.5.13: Oil Switch Maintenance - Replacement

- 7.5.13.1: CEI - The Illuminating Company

- 7.5.13.2: Duke Energy Florida

- 7.5.13.3: PG&E

- 7.5.13.4: Survey Results

- 7.5.14: Organization

- 7.5.14.1: AEP - Ohio

- 7.5.14.2: Ameren Missouri

- 7.5.14.3: CEI - The Illuminating Company

- 7.5.14.4: CenterPoint Energy

- 7.5.14.5: Con Edison - Consolidated Edison

- 7.5.14.6: Duke Energy Florida

- 7.5.14.7: Duke Energy Ohio

- 7.5.14.8: Energex

- 7.5.14.9: ESB Networks

- 7.5.14.10: Georgia Power

- 7.5.14.11: HECO - The Hawaiian Electric Company

- 7.5.14.12: National Grid

- 7.5.14.13: PG&E

- 7.5.14.14: Portland General Electric

- 7.5.14.15: SCL - Seattle City Light

- 7.5.14.16: Survey Results

- 7.5.15: Padmounted Transformer Inspection

- 7.5.15.1: CenterPoint Energy

- 7.5.15.2: Survey Results

- 7.5.16: Pipe Cable System Maintenance

- 7.5.16.1: CEI - The Illuminating Company

- 7.5.16.2: Duke Energy Ohio

- 7.5.16.3: HECO - The Hawaiian Electric Company

- 7.5.16.4: SCL - Seattle City Light

- 7.5.17: Preventive Maintenance and Inspection

- 7.5.17.1: AEP - Ohio

- 7.5.17.2: Ameren Missouri

- 7.5.17.3: CEI - The Illuminating Company

- 7.5.17.4: CenterPoint Energy

- 7.5.17.5: Con Edison - Consolidated Edison

- 7.5.17.6: Duke Energy Florida

- 7.5.17.7: Duke Energy Ohio

- 7.5.17.8: Energex

- 7.5.17.9: ESB Networks

- 7.5.17.10: Georgia Power

- 7.5.17.11: HECO - The Hawaiian Electric Company

- 7.5.17.12: National Grid

- 7.5.17.13: PG&E

- 7.5.17.14: Portland General Electric

- 7.5.17.15: SCL - Seattle City Light

- 7.5.17.16: Survey Results

- 7.5.18: Strategic Inspection and Maintenance System

- 7.5.18.1: Con Edison - Consolidated Edison

- 7.5.18.2: Energex

- 7.5.18.3: HECO - The Hawaiian Electric Company

- 7.5.18.4: Survey Results

- 7.5.19: Switchgear Inspection and Maintenance

- 7.5.19.1: Duke Energy Florida

- 7.5.20: Terminator Maintenance (37kV)

- 7.5.20.1: CEI - The Illuminating Company

- 7.5.21: Testing Laboratory

- 7.5.21.1: AEP - Ohio

- 7.5.21.2: Ameren Missouri

- 7.5.21.3: CEI - The Illuminating Company

- 7.5.21.4: CenterPoint Energy

- 7.5.21.5: Con Edison - Consolidated Edison

- 7.5.21.6: Duke Energy Florida

- 7.5.21.7: Duke Energy Ohio

- 7.5.21.8: Energex

- 7.5.21.9: ESB Networks

- 7.5.21.10: Georgia Power

- 7.5.21.11: PG&E

- 7.5.21.12: SCL - Seattle City Light

- 7.5.21.13: National Grid

- 7.5.22: Vault - Manhole - Cleanup

- 7.5.22.1: AEP - Ohio

- 7.5.22.2: Ameren Missouri

- 7.5.22.3: Duke Energy Florida

- 7.5.22.4: Georgia Power

- 7.5.22.5: PG&E

- 7.5.22.6: Portland General Electric

- 7.5.22.7: References

- 7.6: Operations

- 7.6.1: Determining a Feeder to be De-energized

- 7.6.1.1: AEP - Ohio

- 7.6.1.2: Ameren Missouri

- 7.6.1.3: CEI - The Illuminating Company

- 7.6.1.4: CenterPoint Energy

- 7.6.1.5: Con Edison - Consolidated Edison

- 7.6.1.6: Duke Energy Florida

- 7.6.1.7: Duke Energy Ohio

- 7.6.1.8: ESB Networks

- 7.6.1.9: Georgia Power

- 7.6.1.10: HECO - The Hawaiian Electric Company

- 7.6.1.11: National Grid

- 7.6.1.12: PG&E

- 7.6.1.13: Portland General Electric

- 7.6.1.14: Survey Results

- 7.6.2: Dispatching

- 7.6.2.1: AEP - Ohio

- 7.6.2.2: CEI - The Illuminating Company

- 7.6.2.3: CenterPoint Energy

- 7.6.2.4: Duke Energy Florida

- 7.6.2.5: Energex

- 7.6.2.6: ESB Networks

- 7.6.2.7: Georgia Power

- 7.6.2.8: HECO - The Hawaiian Electric Company

- 7.6.2.9: SCL - Seattle City Light

- 7.6.3: Fault Indicators

- 7.6.3.1: AEP - Ohio

- 7.6.3.2: Ameren Missouri

- 7.6.3.3: CEI - The Illuminating Company

- 7.6.3.4: CenterPoint Energy

- 7.6.3.5: Con Edison - Consolidated Edison

- 7.6.3.6: Duke Energy Florida

- 7.6.3.7: Duke Energy Ohio

- 7.6.3.8: Energex

- 7.6.3.9: ESB Networks

- 7.6.3.10: Georgia Power

- 7.6.3.11: HECO - The Hawaiian Electric Company

- 7.6.3.12: National Grid

- 7.6.3.13: PG&E

- 7.6.3.14: References

- 7.6.3.15: Survey Results

- 7.6.4: Fault Location

- 7.6.4.1: AEP - Ohio

- 7.6.4.2: Ameren Missouri

- 7.6.4.3: CEI - The Illuminating Company

- 7.6.4.4: CenterPoint Energy

- 7.6.4.5: Con Edison - Consolidated Edison

- 7.6.4.6: Duke Energy Florida

- 7.6.4.7: Duke Energy Ohio

- 7.6.4.8: Energex

- 7.6.4.9: ESB Networks

- 7.6.4.10: Georgia Power

- 7.6.4.11: HECO - The Hawaiian Electric Company

- 7.6.4.12: National Grid

- 7.6.4.13: PG&E

- 7.6.4.14: Portland General Electric

- 7.6.4.15: References

- 7.6.4.16: Survey Results

- 7.6.5: Flood Plan

- 7.6.5.1: Energex

- 7.6.6: Fuse Stick

- 7.6.6.1: HECO - The Hawaiian Electric Company

- 7.6.7: Incoming Materials Inspection

- 7.6.7.1: Duke Energy Florida

- 7.6.7.2: Energex

- 7.6.7.3: Georgia Power

- 7.6.8: Load Shedding

- 7.6.8.1: CEI - The Illuminating Company

- 7.6.8.2: CenterPoint Energy

- 7.6.8.3: Con Edison - Consolidated Edison

- 7.6.8.4: Duke Energy Ohio

- 7.6.8.5: HECO - The Hawaiian Electric Company

- 7.6.8.6: National Grid

- 7.6.8.7: PG&E

- 7.6.8.8: SCL - Seattle City Light

- 7.6.9: Network Protector Fuse Test

- 7.6.9.1: Duke Energy Florida

- 7.6.9.2: Duke Energy Ohio

- 7.6.9.3: Georgia Power

- 7.6.10: Operations Practices - Clearances

- 7.6.10.1: AEP - Ohio

- 7.6.10.2: Ameren Missouri

- 7.6.10.3: CEI - The Illuminating Company

- 7.6.10.4: CenterPoint Energy

- 7.6.10.5: Con Edison - Consolidated Edison

- 7.6.10.6: Duke Energy Florida

- 7.6.10.7: Duke Energy Ohio

- 7.6.10.8: Energex

- 7.6.10.9: ESB Networks

- 7.6.10.10: Georgia Power

- 7.6.10.11: HECO - The Hawaiian Electric Company

- 7.6.10.12: National Grid

- 7.6.10.13: PG&E

- 7.6.10.14: Portland General Electric

- 7.6.10.15: SCL - Seattle City Light

- 7.6.10.16: Survey Results

- 7.6.11: Organization - Operation Center

- 7.6.11.1: AEP - Ohio

- 7.6.11.2: Ameren Missouri

- 7.6.11.3: CEI - The Illuminating Company

- 7.6.11.4: CenterPoint Energy

- 7.6.11.5: Con Edison - Consolidated Edison

- 7.6.11.6: Duke Energy Florida

- 7.6.11.7: Duke Energy Ohio

- 7.6.11.8: Energex

- 7.6.11.9: ESB Networks

- 7.6.11.10: Georgia Power

- 7.6.11.11: HECO - The Hawaiian Electric Company

- 7.6.11.12: National Grid

- 7.6.11.13: PG&E

- 7.6.11.14: Portland General Electric

- 7.6.11.15: SCL - Seattle City Light

- 7.6.11.16: Survey Results

- 7.6.12: Outage Drills

- 7.6.12.1: AEP - Ohio

- 7.6.12.2: Ameren Missouri

- 7.6.12.3: CEI - The Illuminating Company

- 7.6.12.4: CenterPoint Energy

- 7.6.12.5: Con Edison - Consolidated Edison

- 7.6.12.6: Duke Energy Florida

- 7.6.12.7: Duke Energy Ohio

- 7.6.12.8: Energex

- 7.6.12.9: Georgia Power

- 7.6.12.10: HECO - The Hawaiian Electric Company

- 7.6.12.11: National Grid

- 7.6.12.12: PG&E

- 7.6.12.13: Portland General

- 7.6.12.14: SCL - Seattle City Light

- 7.6.12.15: Survey Results

- 7.6.13: Outages - Restoration

- 7.6.13.1: AEP - Ohio

- 7.6.13.2: Ameren Missouri

- 7.6.13.3: CEI - The Illuminating Company

- 7.6.13.4: CenterPoint Energy

- 7.6.13.5: Con Edison - Consolidated Edison

- 7.6.13.6: Duke Energy Florida

- 7.6.13.7: Duke Energy Ohio

- 7.6.13.8: Energex

- 7.6.13.9: ESB Networks

- 7.6.13.10: Georgia Power

- 7.6.13.11: HECO - The Hawaiian Electric Company

- 7.6.13.12: National Grid

- 7.6.13.13: PG&E

- 7.6.13.14: Portland General Electric

- 7.6.13.15: SCL - Seattle City Light

- 7.6.13.16: Survey Results

- 7.6.14: Picking Up Multiple Feeders after a Network Outage

- 7.6.14.1: AEP - Ohio

- 7.6.14.2: Ameren Missouri

- 7.6.14.3: CEI - The Illuminating Company

- 7.6.14.4: CenterPoint Energy

- 7.6.14.5: Con Edison - Consolidated Edison

- 7.6.14.6: Duke Energy Florida

- 7.6.14.7: Duke Energy Ohio

- 7.6.14.8: Georgia Power

- 7.6.14.9: HECO - The Hawaiian Electric Company

- 7.6.14.10: National Grid

- 7.6.14.11: PG&E

- 7.6.14.12: Portland General Electric

- 7.6.14.13: SCL - Seattle City Light

- 7.6.14.14: Practices Comparison

- 7.6.14.15: Survey Results

- 7.6.15: Primary Trouble Man (PTM)

- 7.6.15.1: HECO - The Hawaiian Electric Company

- 7.6.16: Remote Monitoring - SCADA

- 7.6.16.1: AEP - Ohio

- 7.6.16.2: Ameren Missouri

- 7.6.16.3: CEI - The Illuminating Company

- 7.6.16.4: CenterPoint Energy

- 7.6.16.5: Con Edison - Consolidated Edison

- 7.6.16.6: Duke Energy Florida

- 7.6.16.7: Duke Energy Ohio

- 7.6.16.8: Energex

- 7.6.16.9: ESB Networks

- 7.6.16.10: Georgia Power

- 7.6.16.11: HECO - The Hawaiian Electric Company

- 7.6.16.12: National Grid

- 7.6.16.13: PG&E

- 7.6.16.14: Portland General Electic

- 7.6.16.15: SCL - Seattle City Light

- 7.6.16.16: References

- 7.6.16.17: Survey Results

- 7.6.17: Sound Coil

- 7.6.17.1: CEI - The Illuminating Company

- 7.6.18: Temporary Overhead Jumpers

- 7.6.18.1: HECO - The Hawaiian Electric Company

- 7.6.19: Three Phase Transformer Change Outs – Hot Cap Proc

- 7.6.19.1: HECO - The Hawaiian Electric Company

- 7.7: Planning

- 7.7.1: Asset Management

- 7.7.1.1: AEP - Ohio

- 7.7.1.2: Ameren Missouri

- 7.7.1.3: CEI - The Illuminating Company

- 7.7.1.4: CenterPoint Energy

- 7.7.1.5: Con Edison - Consolidated Edison

- 7.7.1.6: Duke Energy Florida

- 7.7.1.7: Duke Energy Ohio

- 7.7.1.8: Energex

- 7.7.1.9: ESB Networks

- 7.7.1.10: Georgia Power

- 7.7.1.11: HECO - The Hawaiian Electric Company

- 7.7.1.12: National Grid

- 7.7.1.13: PG&E

- 7.7.1.14: Portland General Electric

- 7.7.1.15: San Diego Gas and Electric

- 7.7.1.16: SCL - Seattle City Light

- 7.7.2: Cable Rating

- 7.7.2.1: AEP - Ohio

- 7.7.2.2: Ameren Missouri

- 7.7.2.3: CEI - The Illuminating Company

- 7.7.2.4: CenterPoint Energy

- 7.7.2.5: Con Edison - Consolidated Edison

- 7.7.2.6: Duke Energy Florida

- 7.7.2.7: Duke Energy Ohio

- 7.7.2.8: Energex

- 7.7.2.9: ESB Networks

- 7.7.2.10: Georgia Power

- 7.7.2.11: HECO - The Hawaiian Electric Company

- 7.7.2.12: National Grid

- 7.7.2.13: PG&E

- 7.7.2.14: Portland General Electric

- 7.7.2.15: SCL - Seattle City Light

- 7.7.2.16: References

- 7.7.2.17: Survey Results

- 7.7.3: Cable Replacement Strategy

- 7.7.3.1: AEP - Ohio

- 7.7.3.2: Ameren Missouri

- 7.7.3.3: CEI - The Illuminating Company

- 7.7.3.4: Duke Energy Florida

- 7.7.3.5: Duke Energy Ohio

- 7.7.3.6: Energex

- 7.7.3.7: ESB Networks

- 7.7.3.8: Georgia Power

- 7.7.3.9: HECO - The Hawaiian Electric Company

- 7.7.3.10: National Grid

- 7.7.3.11: PG&E

- 7.7.3.12: Portland General Electric

- 7.7.3.13: Survey Results

- 7.7.4: Circuit Modeling

- 7.7.4.1: AEP - Ohio

- 7.7.4.2: Ameren Missouri

- 7.7.4.3: CEI - The Illuminating Company

- 7.7.4.4: CenterPoint Energy

- 7.7.4.5: Con Edison - Consolidated Edison

- 7.7.4.6: Duke Energy Florida

- 7.7.4.7: Duke Energy Ohio

- 7.7.4.8: Energex

- 7.7.4.9: ESB Networks

- 7.7.4.10: Georgia Power

- 7.7.4.11: HECO - The Hawaiian Electric Company

- 7.7.4.12: National Grid

- 7.7.4.13: PG&E

- 7.7.4.14: Portland General Electric

- 7.7.4.15: SCL - Seattle City Light

- 7.7.4.16: Practices Comparison

- 7.7.4.17: References

- 7.7.4.18: Survey Results

- 7.7.5: Contingency Planning

- 7.7.5.1: AEP - Ohio

- 7.7.5.2: Ameren Missouri

- 7.7.5.3: CEI - The Illuminating Company

- 7.7.5.4: CenterPoint Energy

- 7.7.5.5: Con Edison - Consolidated Edison

- 7.7.5.6: Duke Energy Florida

- 7.7.5.7: Duke Energy Ohio

- 7.7.5.8: Energex

- 7.7.5.9: ESB Networks

- 7.7.5.10: Georgia Power

- 7.7.5.11: HECO - The Hawaiian Electric Company

- 7.7.5.12: National Grid

- 7.7.5.13: PG&E

- 7.7.5.14: Portland General Electric

- 7.7.5.15: SCL - Seattle City Light

- 7.7.5.16: Survey Results

- 7.7.6: Distributed Generation

- 7.7.6.1: AEP - Ohio

- 7.7.6.2: Ameren Missouri

- 7.7.6.3: CEI - The Illuminating Company

- 7.7.6.4: CenterPoint Energy

- 7.7.6.5: Duke Energy Florida

- 7.7.6.6: Duke Energy Ohio

- 7.7.6.7: Energex

- 7.7.6.8: ESB Networks

- 7.7.6.9: Georgia Power

- 7.7.6.10: HECO - The Hawaiian Electric Company

- 7.7.6.11: National Grid

- 7.7.6.12: PG&E

- 7.7.6.13: Portland General Electric

- 7.7.6.14: References

- 7.7.6.15: Survey Results

- 7.7.7: Distribution Automation Control in Contingencies

- 7.7.7.1: CenterPoint Energy

- 7.7.8: Intermittent Supply Forecasting

- 7.7.8.1: Energex

- 7.7.9: Load Forecasting

- 7.7.9.1: AEP - Ohio

- 7.7.9.2: Ameren Missouri

- 7.7.9.3: CEI - The Illuminating Company

- 7.7.9.4: CenterPoint Energy

- 7.7.9.5: Con Edison - Consolidated Edison

- 7.7.9.6: Duke Energy Florida

- 7.7.9.7: Duke Energy Ohio

- 7.7.9.8: Energex

- 7.7.9.9: ESB Networks

- 7.7.9.10: Georgia Power

- 7.7.9.11: HECO - The Hawaiian Electric Company

- 7.7.9.12: National Grid

- 7.7.9.13: PG&E

- 7.7.9.14: Portland General Electric

- 7.7.9.15: Survey Results

- 7.7.10: Load Relief

- 7.7.10.1: Ameren Missouri

- 7.7.10.2: CEI - The Illuminating Company

- 7.7.10.3: CenterPoint Energy

- 7.7.10.4: Con Edison - Consolidated Edison

- 7.7.10.5: Duke Energy Florida

- 7.7.10.6: Duke Energy Ohio

- 7.7.10.7: Energex

- 7.7.10.8: ESB Networks

- 7.7.10.9: Georgia Power

- 7.7.10.10: HECO - The Hawaiian Electric Company

- 7.7.10.11: National Grid

- 7.7.10.12: PG&E

- 7.7.10.13: SCL - Seattle City Light

- 7.7.10.14: Survey Results

- 7.7.11: Network Planning

- 7.7.11.1: AEP - Ohio

- 7.7.11.2: Ameren Missouri

- 7.7.11.3: CEI - The Illuminating Company

- 7.7.11.4: CenterPoint Energy

- 7.7.11.5: Con Edison - Consolidated Edison

- 7.7.11.6: Duke Energy Florida

- 7.7.11.7: Duke Energy Ohio

- 7.7.11.8: Energex

- 7.7.11.9: ESB Networks

- 7.7.11.10: Georgia Power

- 7.7.11.11: HECO - The Hawaiian Electric Company

- 7.7.11.12: National Grid

- 7.7.11.13: PG&E

- 7.7.11.14: Portland General Electric

- 7.7.11.15: SCL - Seattle City Light

- 7.7.11.16: Survey Results

- 7.7.12: Organization

- 7.7.12.1: AEP - Ohio

- 7.7.12.2: Ameren Missouri

- 7.7.12.3: CEI - The Illuminating Company

- 7.7.12.4: CenterPoint Energy

- 7.7.12.5: Con Edison - Consolidated Edison

- 7.7.12.6: Duke Energy Florida

- 7.7.12.7: Duke Energy Ohio

- 7.7.12.8: Energex

- 7.7.12.9: ESB Networks

- 7.7.12.10: Georgia Power

- 7.7.12.11: HECO - The Hawaiian Electric Company

- 7.7.12.12: National Grid

- 7.7.12.13: PG&E

- 7.7.12.14: Portland General Electric

- 7.7.12.15: SCL - Seattle City Light

- 7.7.12.16: Survey Results

- 7.7.13: Program Management

- 7.7.13.1: Duke Energy Florida

- 7.7.13.2: Energex

- 7.7.13.3: ESB Networks

- 7.7.13.4: Georgia Power

- 7.7.14: System Protection

- 7.7.14.1: AEP - Ohio

- 7.7.14.2: Ameren Missouri

- 7.7.14.3: CEI - The Illuminating Company

- 7.7.14.4: CenterPoint Energy

- 7.7.14.5: Duke Energy Florida

- 7.7.14.6: Duke Energy Ohio

- 7.7.14.7: Energex

- 7.7.14.8: ESB Networks

- 7.7.14.9: Georgia Power

- 7.7.14.10: National Grid

- 7.7.14.11: PG&E

- 7.7.14.12: Portland General Electric

- 7.7.14.13: References

- 7.7.14.14: Survey Results

- 7.8: Safety

- 7.8.1: 2020 Vision Program

- 7.8.1.1: Portland General Electric

- 7.8.2: Accident - Incident Investigation

- 7.8.2.1: Ameren Missouri

- 7.8.2.2: CEI - The Illuminating Company

- 7.8.2.3: CenterPoint Energy

- 7.8.2.4: Con Edison - Consolidated Edison

- 7.8.2.5: Duke Energy Florida

- 7.8.2.6: Duke Energy Ohio

- 7.8.2.7: Energex

- 7.8.2.8: ESB Networks

- 7.8.2.9: Georgia Power

- 7.8.2.10: HECO - The Hawaiian Electric Company

- 7.8.2.11: National Grid

- 7.8.2.12: PG&E

- 7.8.2.13: SCL - Seattle City Light

- 7.8.3: Arc Suppression Blankets

- 7.8.3.1: CenterPoint Energy

- 7.8.3.2: Duke Energy Florida

- 7.8.3.3: HECO - The Hawaiian Electric Company

- 7.8.3.4: Survey Results

- 7.8.4: Career Development Program

- 7.8.4.1: Con Edison - Consolidated Edison

- 7.8.4.2: Survey Results

- 7.8.5: Contractor Safety Orientation and Certification

- 7.8.5.1: Duke Energy Florida

- 7.8.5.2: HECO - The Hawaiian Electric Company

- 7.8.5.3: PG&E

- 7.8.6: Field Safety Person

- 7.8.6.1: Ameren Missouri

- 7.8.6.2: Duke Energy Ohio

- 7.8.6.3: Georgia Power

- 7.8.6.4: HECO - The Hawaiian Electric Company

- 7.8.6.5: National Grid

- 7.8.6.6: PG&E

- 7.8.6.7: Survey Results

- 7.8.7: Lead Cable Safety

- 7.8.7.1: AEP - Ohio

- 7.8.7.2: Ameren Missouri

- 7.8.7.3: Energex

- 7.8.7.4: Georgia Power

- 7.8.7.5: National Grid

- 7.8.7.6: PG&E

- 7.8.8: Manhole - Vault Entry

- 7.8.8.1: AEP - Ohio

- 7.8.8.2: Ameren Missouri

- 7.8.8.3: CEI - The Illuminating Company

- 7.8.8.4: CenterPoint Energy

- 7.8.8.5: Con Edison - Consolidated Edison

- 7.8.8.6: Duke Energy Florida

- 7.8.8.7: Duke Energy Ohio

- 7.8.8.8: Energex

- 7.8.8.9: Georgia Power

- 7.8.8.10: HECO - The Hawaiian Electric Company

- 7.8.8.11: National Grid

- 7.8.8.12: PG&E

- 7.8.8.13: SCL - Seattle City Light

- 7.8.8.14: Practices Comparison

- 7.8.8.15: References

- 7.8.8.16: Survey Results

- 7.8.9: Morning Stretch

- 7.8.9.1: AEP - Ohio

- 7.8.9.2: Ameren Missouri

- 7.8.9.3: Duke Energy Florida

- 7.8.9.4: Georgia Power

- 7.8.9.5: HECO - The Hawaiian Electric Company

- 7.8.9.6: National Grid

- 7.8.9.7: PG&E

- 7.8.9.8: Survey Results

- 7.8.10: Near Miss Program

- 7.8.10.1: AEP - Ohio

- 7.8.10.2: Ameren Missouri

- 7.8.10.3: CEI - The Illuminating Company

- 7.8.10.4: CenterPoint Energy

- 7.8.10.5: Con Edison - Consolidated Edison

- 7.8.10.6: Duke Energy Florida

- 7.8.10.7: Energex

- 7.8.10.8: ESB Networks

- 7.8.10.9: Georgia Power

- 7.8.10.10: HECO - The Hawaiian Electric Company

- 7.8.10.11: National Grid

- 7.8.10.12: PG&E

- 7.8.10.13: Portland General Electric

- 7.8.11: Operating a 5KV Underground Oil Switch

- 7.8.11.1: CEI - The Illuminating Company

- 7.8.11.2: PG&E

- 7.8.12: Operating Errors Investigations

- 7.8.12.1: CEI - The Illuminating Company

- 7.8.12.2: Con Edison - Consolidated Edison

- 7.8.12.3: HECO - The Hawaiian Electric Company

- 7.8.12.4: SCL - Seattle City Light

- 7.8.13: Organization

- 7.8.13.1: AEP - Ohio

- 7.8.13.2: Ameren Missouri

- 7.8.13.3: CEI - The Illuminating Company

- 7.8.13.4: CenterPoint Energy

- 7.8.13.5: Con Edison - Consolidated Edison

- 7.8.13.6: Duke Energy Florida

- 7.8.13.7: Duke Energy Ohio

- 7.8.13.8: Energex

- 7.8.13.9: ESB Networks

- 7.8.13.10: Georgia Power

- 7.8.13.11: HECO - The Hawaiian Electric Company

- 7.8.13.12: National Grid

- 7.8.13.13: PG&E

- 7.8.13.14: Portland General Electric

- 7.8.13.15: SCL - Seattle City Light

- 7.8.13.16: Survey Results

- 7.8.14: Personal Protective Equipment

- 7.8.14.1: AEP - Ohio

- 7.8.14.2: Ameren Missouri

- 7.8.14.3: CEI - The Illuminating Company

- 7.8.14.4: CenterPoint Energy

- 7.8.14.5: Con Edison - Consolidated Edison

- 7.8.14.6: Duke Energy Florida

- 7.8.14.7: Duke Energy Ohio

- 7.8.14.8: Energex

- 7.8.14.9: ESB Networks

- 7.8.14.10: Georgia Power

- 7.8.14.11: HECO - The Hawaiian Electric Company

- 7.8.14.12: National Grid

- 7.8.14.13: PG&E

- 7.8.14.14: SCL - Seattle City Light

- 7.8.14.15: References

- 7.8.14.16: Survey Results

- 7.8.15: Safety Communication

- 7.8.15.1: Ameren Missouri

- 7.8.15.2: CEI - The Illuminating Company

- 7.8.15.3: Con Edison - Consolidated Edison

- 7.8.15.4: Duke Energy Florida

- 7.8.15.5: Duke Energy Ohio

- 7.8.15.6: Energex

- 7.8.15.7: Georgia Power

- 7.8.15.8: National Grid

- 7.8.15.9: PG&E

- 7.8.15.10: Portland General Electric

- 7.8.15.11: Survey Results

- 7.8.16: Safety Meetings

- 7.8.16.1: AEP - Ohio

- 7.8.16.2: Ameren Missouri

- 7.8.16.3: CEI - The Illuminating Company

- 7.8.16.4: CenterPoint Energy

- 7.8.16.5: Con Edison - Consolidated Edison

- 7.8.16.6: Duke Energy Florida

- 7.8.16.7: Duke Energy Ohio

- 7.8.16.8: Energex

- 7.8.16.9: ESB Networks

- 7.8.16.10: Georgia Power

- 7.8.16.11: HECO - The Hawaiian Electric Company

- 7.8.16.12: National Grid

- 7.8.16.13: PG&E

- 7.8.16.14: Portland General Electric

- 7.8.16.15: SCL - Seattle City Light

- 7.8.16.16: Survey Results

- 7.8.17: Safety Observations

- 7.8.17.1: AEP - Ohio

- 7.8.17.2: Ameren Missouri

- 7.8.17.3: CenterPoint Energy

- 7.8.17.4: Con Edison - Consolidated Edison

- 7.8.17.5: Duke Energy Florida

- 7.8.17.6: Duke Energy Ohio

- 7.8.17.7: Energex

- 7.8.17.8: ESB Networks

- 7.8.17.9: Georgia Power

- 7.8.17.10: National Grid

- 7.8.17.11: PG&E

- 7.8.17.12: Portland General Electric

- 7.8.17.13: Survey Results

- 7.8.18: Special Safety Programs

- 7.8.18.1: Ameren Missouri

- 7.8.18.2: CEI The Illuminating Company

- 7.8.18.3: CenterPoint Energy

- 7.8.18.4: Duke Energy Florida

- 7.8.18.5: Duke Energy Ohio

- 7.8.18.6: Energex

- 7.8.18.7: Georgia Power

- 7.8.18.8: National Grid

- 7.8.18.9: Portland General Electric

- 7.8.18.10: SCL-Seattle City Light

- 7.8.19: Training

- 7.8.19.1: AEP - Ohio

- 7.8.19.2: Ameren Missouri

- 7.8.19.3: CEI - The Illuminating Company

- 7.8.19.4: CenterPoint Energy

- 7.8.19.5: Duke Energy Florida

- 7.8.19.6: Duke Energy Ohio

- 7.8.19.7: Energex

- 7.8.19.8: ESB Networks

- 7.8.19.9: Georgia Power

- 7.8.19.10: National Grid

- 7.8.19.11: PG&E

- 7.8.19.12: Portland General Electric

- 7.9: Survey Results

- 7.9.1: 2009 Survey Results

- 7.9.1.1: Summary - Overview

- 7.9.1.2: Summary - Physical/General

- 7.9.1.3: Planning

- 7.9.1.4: Design

- 7.9.1.5: Construction

- 7.9.1.6: Maintenance

- 7.9.1.7: Operations

- 7.9.1.8: Safety

- 7.9.1.9: Distributed Generation

- 7.9.1.10: Practices of Note

- 7.9.2: 2012 Survey Results

- 7.9.2.1: Summary - Overview

- 7.9.2.2: Summary - Physical/General

- 7.9.2.3: Planning

- 7.9.2.4: Design

- 7.9.2.5: Construction

- 7.9.2.6: Maintenance

- 7.9.2.7: Operations

- 7.9.2.8: Safety

- 7.9.2.9: Distributed Generation

- 7.9.2.10: Practices of Note

- 7.9.3: 2015 Survey Results

- 7.9.3.1: Summary - Overview

- 7.9.3.2: Summary - Physical/General

- 7.9.3.3: Planning

- 7.9.3.4: Design

- 7.9.3.5: Maintenance

- 7.9.3.6: Operations

- 7.9.3.7: Safety

- 7.9.3.8: Practices of Note

- 7.9.4: 2018 Survey Results

- 7.9.4.1: Asset Management

- 7.9.4.2: Manhole Event Preparedness and Response

- 7.9.4.3: Urban Network Safety Practices Survey

- 7.9.5: 2019 Survey Results

- 7.9.5.1: UG Inspection Practices Survey

- 7.9.6: 2020 Survey Results

- 7.9.6.1: PTO Monitoring Survey

- 7.9.6.2: Underground Residential and Underground Commercial Distribution (URD /UCD) Practices Survey

- 7.9.7: 2021 Survey Results

- 7.9.7.1: Infrared Thermography Survey

- 7.9.8: 2022 Survey Results

1 - Bronze Book

The Electric Power Research Institute (EPRI) has developed the 2022 update of the EPRI Underground Distribution Systems Reference Book (Bronze Book). This reference, authored by leading industry expert authors, joins the EPRI series of Power Delivery technical references, commonly known by the color of their covers.

The Bronze Book has been written to be a meaningful reference to utility engineers and personnel involved in the planning, design, manufacture, installation, operation, and maintenance of underground distribution systems. Its development was driven by the impending loss of institutional knowledge through attrition and retirement of experienced resources, and the consequent urgent need to document industry knowledge and practices.

The Bronze Book contains chapter sections that provide information on the state of the industry with respect to underground distribution systems, network and nonnetwork system planning and design, cable ampacity, system protection, civil and electrical construction, underground maintenance and operations including fault location and cable diagnostics, reliability, corrosion, and equipment such as cables, cable accessories, transformers, and capacitors.

The 2023 edition of the EPRI Underground Distribution Systems Reference Book includes a new chapter on “Underground Cable System Quality.”

Download EPRI Underground Distribution Systems Reference Book: 2023 Update here.

2 - Utility Information Exchange

The Utility Information Exchange (UIE) is designed to facilitate the sharing of experiences amongst EPRI member companies within the specific topic that is the subject of the meeting. This document contains the notes gathered during the call and are meant only for members of the P180.002 Distribution Underground project. The information shared during this webcast is used in part to help guide / inform the research work undertaken within the project.

2.1 - P180.002 Underground 2021 ARP Utility Information Exchange - June 17, 2021

Attendees

The UIE was attended by EPRI member companies and EPRI staff. The list of member company attendees appears in Table 1.

| Company | Name |

|---|---|

| AEP | Cory Jeffers |

| Ameren | John Rowland |

| Central Hudson | Taryn Black |

| Con Edison | Tom Campbell, Yingli Wen |

| Consumers Energy | Mark Lyons |

| DTE | Naera Haghnazarian, Adam Jacobs, Abdalla Sadoon |

| Exelon - ComEd | Jimi Conway, Urbano Gallardo |

| Exelon - PHI | Andrew Deen |

| First Energy | Dean Phillips |

| HECO | Randall Tom, Charlyne Nakamura |

| National Grid | Hernan Yepez |

| PECO | Dustin Nace |

| Portland General Electric | Jeff Kaiser |

| Salt River Project | Logan Tsinigine, Rick Hudson, Jason Gunawardena |

| Southern Company - APC | Stephen Daniel |

| Southern Company - GPC | Mike Pearman |

| Southern Company - MPC | Robery Boyd |

| Taiwan Power | Will Chang |

| WEC Energy | Mike Smalley |

Utility Information Exchange Summary

The following sections provide a summary of the responses gathered during the individual question roundtables.

Question 1: Utilization of Remote Monitoring

The first question posed to the group contained multiple parts:

- Are you utilizing any remote monitoring outside the substation?

- Where?

- What are you are monitoring?

- On what equipment is it being applied?

- What technology are you using?

- How are you communicating?

The following responses were shared:

- Consumers Energy

- Gave a presentation at the 2017 NADUUWG presentation on “Circuit West” where a pilot for online monitoring was underway

- Pilot uses localized fiber optic network

- Able to monitor load, switch positions, relays, and is control-enabled

- The circuit is a hybrid circuit – duct and manhole non-network that connects to URD system

- SCADA enabled equipment is connected to this system

- HECO

- Most monitoring implemented at HECO is in the substation. Efforts now beginning at augmenting with monitoring technology outside the substation

- Data is brought back through SCADA

- Initially looking at faulted circuit indicators (FCI’s) to help with fault locating activities

- Also monitoring recloser status / operation

- Communication is primarily through cellular back to control center

- Network improvements are underway including installation of fiber optic to all vaults. Now in second or third year of 5 year program.

- SRP

- Using faulted circuit indicators and reclosers (IntelliRupter®)

- Cooper fault indicators are connected through Verizon cellular

- IntelliRupters® (several tens of them installed) are monitored through field area network and wireless where needed

- Replacing capacitor controllers with Cooper product that ties into SRP area network

- Power quality monitoring at large industrial customers is also in place.

- PQ monitors in place to capture large voltage swings at the customer switchgear or substation depending on the situation

- Monitoring primarily current and sometimes voltage at cap banks

- Also have one switch outfitted with current and fault indication monitoring capability

- Using faulted circuit indicators and reclosers (IntelliRupter®)

- AEP

- Currently employing extensive real time monitoring capability, including:

- Circuit loading

- Temperature

- Oil pressure

- Status on vacuum interrupters, network protectors, etc.

- Network and secondary voltage

- Using Eaton VaultGard communications platform

- Fiber backbone installed at all vault locations to act as communications channel.

- Data are collected at local cluster locations, compiled, then fed back to a centralized location

- Currently preparing/implementing pilot program to look at real-time distributed temperature sensing (DTS) for real time cable ampacity ratings.

- Looking to use single fiber run within each duct bank to sense temperatures in adjacent ducts

- Aiming to eliminate need to run CYMCAP calculations

- Currently employing extensive real time monitoring capability, including:

- FirstEnergy

- Not currently utilizing monitoring outside of the substation

- Twelve networks (small)

- Monitoring tied in through SCADA

- Currently using some fault indicators to monitor portions of URD system

- Not currently utilizing monitoring outside of the substation

- Ameren

- Currently monitoring radial and network UG systems.

- Using S&C IntelliTeam® equipment

- Padmount switchgear

- IntelliRupters®

- Switchgear inside building

- Monitoring includes several features:

- Switch status

- Fault status

- Voltage

- Current, etc.

- Network protectors include monitoring as well. This includes:

- Status

- Water level

- Handle position

- Looking to add pressure, temperature, and oil level (PTO) sensors

- ETI relaying on 277 V network protectors

- Eaton CM52 on 480 V network protectors

- Communications system is radial cell system through a private vendor

- Considered adding fiber but currently building private LTE network for Ameren. May move to that for all network protectors with a targeted 2022 start up

- National Grid

- Utilizing monitoring on their network system

- Currently undertaking a monitoring pilot project in Buffalo. Project will include transformer monitoring including:

- Online transformer DGA (likely Qualitrol multi-gas module)

- Oil temperature

- Volt-var optimization (VVO) to come

- Exelon - PHI

- Monitoring is use on network system and is focused on network transformers

- Communications are via RMS system – radio backbone through Itron

- Monitored features include:

- Water level

- Temperature

- Pressure (primary and NP)

- Status

- Also conducting pilot program with Richards ETI & Eaton solutions

- Exploring use of other equipment for automatic restoration and fault location:

- Smart fault circuit indicators from Sentient

- Underground interrupters which are similar to a recloser but without reclosing capability.

- Pilot underway on condition assessment monitoring technology:

- Active partial discharge monitoring system for cables.

- Planning to use on several feeders which include river crossings or are historically poor performers.

- Believe communications will be Cellular.

- Manufacturer will perform analysis on recorded discharge activity.

- Retrofitting FCI’s on URD system padmount equipment. Planning to expand to network in the future.

- Central Hudson

- Currently working on deployment of monitoring on network system (<50% setup).

- Uses ETI system.

- Monitored features include:

- Current.

- Voltage.

- Network protector status.

- PTO sensors.

- Water ingress.

- Communications via 3rd party cellular.

- Now constructing private wireless network.

- Con Edison

- Monitoring all network transformers using PTO.

- Communication is via RMS powerline carrier system.

- Pilot program looking at integrated T-body sensors which can measure current, voltage, and phase angle.

- DTE

- Conducting pilot study for CNIGuard manhole monitoring unit (1 year complete, starting 2nd year).

- Unit includes multiple sensor types:

- IR camera.

- Combustible gas detection.

- Monitoring current and fault status on network banks.

- Cellular signal for CNIGuard.

- Southern Company - Alabama Power

- Uses feeder communications system.

- SCADA with comms back to operators.

- Monitoring and control of these devices.

- Communications channel is SouthernLink – private cellular LTE system.

- Automatic throwover switches (ATO’s) are on SCADA system.

- All network protectors monitored and communicate via fiber optic network.

- Pilot to monitor network transformers with DGA and temperature monitoring.

- Uses feeder communications system.

- Southern Company - Mississippi Power

- Same as APC excluding network system monitoring.

- Stand by generation agreements with status and control on the switchgear.

- Exelon - PECO

- Monitoring is very limited in underground outside of the substation.

- Current monitoring over fiber optic network.

- Secondary system uses PSI network monitoring for voltage and current. System operation is currently limited.

- Communications through powerline carrier between stations and cellular modem back to central location.

- There have been many issues with this communications path.

- Piloting 3M sensor for measuring voltage, current, temperature, water level.

- Sensus radio for communications.

- One switch being monitored over Sensus radio.

Question 1 Key Takeaways

- Limited deployment of monitoring systems outside of substation with the focus being network systems.

- Field systems to date are focused on measuring voltage, current, and temperature. Additional status indicators are also routinely recorded.

- Several pilot projects underway.

Question 2: Data Interpretation and Usage

The second question for discussion involved the following topic:

- If you are using remote monitoring, please describe how you are using the information.

- Have you established alarms / thresholds?

- What sort of analysis and reporting have you deployed?

The following responses were shared during the roundtable discussion:

- Consumers Energy

- Work mostly on substation equipment not so much out on UG system.

- HECO

- Most work on FCI’s – comes back strictly as an alarm at this time, no data to interpret.

- Not ready to establish threshold levels at this time.

- SRP

* Data from Cap bank controllers has been most useful so far:

- Monitoring the neutral and operation of the cap bank switch.

- Identify if there is abnormal operation of the cap bank switch (e.g. phase gets stuck).

- No response criterion has proven useful as it indicates that troubleshooting is required and a team can be dispatched.

- AEP

- Piloting a few different data interpretation / analysis approaches.

- Cyme software using real time data including AMI data.

- Running state estimator using the data that are coming in.

- Visualization using dashboard view of data (ABB product).

- Incorporating maintenance (DGA) into dashboard.

- Combining different data into visualization.

- Converting all data into “data lake” and housing internally. Enables them to push and pull data across platforms and not have to work with many different datasets

- Working with Eaton to do secondary fault detection using data from network protectors.

- Piloting a few different data interpretation / analysis approaches.

- FirstEnergy

- Nothing to report on this topic.

- Ameren

- Using network data for loading alarms (66% of transformer kVA rating).

- Network protector monitoring allows Ameren to operate in abnormal conditions due to switching during restoration efforts.

- Able to detect equipment failures.

- Conducting a trial for DTS within cable ducts – monitor actual cable temp and identify overloaded circuits.

- Exelon - PHI

- Using data to try and understand how much solar and DER is on the system.

- Also using data to detect backfeed on the system (most likely from DER site).

- Central Hudson

- No established alarms / thresholds.

- Focused on getting relays communicating properly back to central location.

- Working to figure out how to leverage data but focused for the time being on getting everything hooked up and working.

- DTE

- Manhole monitoring system from CNIGuard has internal alarms setup.

- Key personnel receive text messages to dispatch crew when alarm goes off

- Two threshold levels (yellow and red).

- IR camera alarms as well. Alarm triggers on fluctuating temperature.

- Manhole monitoring system from CNIGuard has internal alarms setup.

- Southern Company - Alabama Power

- System in place that collects data from each switching device (SCADA Tools):

- Voltage.

- Current.

- Switch position.

- Open/close.

- Alarms for high voltage, low voltage, and current.

- Network transformer pilot project underway.

- Not collecting the data but planning to start later on.

- System in place that collects data from each switching device (SCADA Tools):

- Mississippi Power

- Same as APC.

- Alarm thresholds set on status fields only (e.g. battery alarm, etc.).

- Exelon - PECO

- PSI secondary monitor (not fully functional right now).

- When working, reported current and provided alarm on set threshold.

- PSI secondary monitor (not fully functional right now).

Question 2 Key Takeaways

- Most participants indicate alarming to be the most common data captured.

- Efforts starting to look at combining data and developing ways to extract information from the data through visualization and other means.

Question 3: Challenges to Implementing Monitoring

The third question for discussion was:

- What was the most difficult challenge to implementing online monitoring?

The following responses were shared during the roundtable discussion:

- Consumers

- Convincing IT to allow engineering to install and connect the monitoring equipment to the system.

- The need to bring on many different consultants with an ambiguous scope.

- HECO

- Retrofitting old equipment with new sensors and other devices. Lots of trial and error trying to adapt the sensors and relays to the old equipment.

- SRP

- Communication problems getting the data back for use.

- Line of sight wireless communication can get blocked.

- Need to monitor the wireless connections.

- May need additional power and maintenance on transmitter system.

- Communication errors cause alarms which need to be addressed and this becomes a problem if there are too many alarms – created group just to handle comms issues.

- Communication problems getting the data back for use.

- AEP

- Size of rollout was a challenge to manage given the numerous different Op-Co’s involved.

- Material issues along the ways

- Submersible subpanels were a problem as they would leak and cause issues with the electronics inside

- Training the crews takes time to get everyone up to speed

- Contractors help at the start but then the management of the system becomes inhouse – “Day 2” after the contractors leave. Need to be ready for this.

- Ameren

- Difficult to keep communications working

- Cell connections had issues at antennas in vaults / manholes.

- Powering up the equipment was an issue.

- CM52’s – comms exit when placed in vault is hard to get to and water can get into the cabinet.

- Had to redesign the bulkheads and put the equipment higher up on the vault wall

- Difficult to keep communications working

- Exelon - PHI

- Issues with maintaining communications.

- Buildings are a problem that they block comms.

- Trucks park over vaults and this disrupts.

- Worked to install repeaters to improve wireless signal.

- Unable to install fiber as it is not considered to be a distribution asset at PHI.

- Training of crews.

- Issues with maintaining communications.

- Central Hudson

- Finding resources to implement / install the equipment has been difficult.

- It is challenging to find an appropriate place to store all the data.

- Current system only stores 13 months of data and then these data need to be moved somewhere else.

- Con Edison

- Sealing of all the boxes for comms and wiring against water ingress. IP68 is not effective enough for vault applications.

- Different generations of monitoring equipment. Procurement of proper connectors and wires has been difficult especially during COVID.

- DTE

- Communications problems.

- Double decker manholes have been a problem.

- Trying to shift to DTE mesh network.

- Communications problems.

- Southern Company - Alabama Power

- Installing new sites for monitoring.

- Initially there were many different groups involved (structures, radios, programmers, etc.) and the process took 6 months to get a location installed and operational.

- Streamlined to be 3-4 weeks now.

- Installing new sites for monitoring.

- Southern Company - Mississippi Power

- Same as APC.

- Exelon - PECO

- Communications are problematic.

- Water intrusion issues which damages electronics.

- Corrosion occurs at the connections.

- Access to resources for getting equipment installed and operational.

Question 3 Key Takeaways

- Communications is the biggest challenge facing utilities in deploying monitoring systems outside the substation.

- Wireless is impacted by structures and other obstacles.

- Utilities are working towards installing fiber systems to overcome communications challenges.

- Suitability of accessories and mounting equipment to manhole / vault environment (i.e. submergence ratings seem optimistic).

- Access to resources and coordinating installation is more complicated than non-monitored situations and so it is difficult to coordinate all the personnel that need to be involved.

- Streamlining can be done but is not simple to implement.

2.2 - P180.002 & P180.004 Issues with Cable Locating and Abandoning Underground Cable – Dec 10, 2021

EPRI Hosts:

- Tom Short, tshort@epri.com, Distribution Safety

- John Tripolitis, jtripolitis@epri.com, Underground Distribution Assets

- Josh Perkel, jperkel@epri.com, Underground Distribution Assets

These are notes from a utility exchange webcast on November 10, 2021.

Introduction:

Utility 1 presentation:

- Abandoned cables have been clouding URD cable locating effort

- Focusing on residential and commercial

- Abandoned cables often aren’t mapped

- Abandoned cables sometimes tone better than the in-use cables

- Standards for abandoning underground cables

- Most cable replacement methods don’t remove the old, buried cables

- Need to map abandoned cables

- Do we electrically “float” the ends?

- Do we ground one or both ends?

- Do standards vary across jacked concentric neutral cables or jacketed cable or secondary cables?

- What are the best practices and techniques for locating the abandoned cables?

Tom Short:

- Shared an application that models the current flow across an energized cable and a parallel abandoned cable.

- The app can be found at: https://distribution.epri.com/safety/2021/ug/

- The model suggests:

- The cable with the bigger neutral is more likely to show up when searching with an active search method.

- Both cables will appear the same using a passive method

- This suggests that it might be best to disconnect the inactive cable at both ends

- The program considers two jacketed concentric neutral cables. The results would vary if one cable is unjacketed.

Have you had issues related to mislocating a cable due to an abandoned cable?

Utility 1: Yes, we’ve had issues with abandoned cable underground.

Utility 2: We do not have issues to the extent that an older city might. We sometimes run into concentric neutral cable, and we are usually able to remove it.

Utility 3: We used to trench and pull out the band cable. This might be more of a problem going forward since we are doing more directional drilling. We have had this issue on a few occasions. We keep our maps up to date.

Utility 4: Yes.

Utility 5: We have had minor issues mislocating, I don’t know if it’s due to abandoned cable. We cut cable below ground and don’t ground it but leave it isolated. For putting something new, it’s not an issue.

Utility 6: Has not heard of any specific issues with this.

Utility 7: Not aware of issue mislocating cables due to abandoned cables.

Does bare concentric neutral vs. jacketed make a difference?

Utility 1: Don’t have many details about cable types, but in one case it was concentric neutral cable where energized was poorly located, but the deenergized cable was located very well.

Utility 2: We have difficulty getting a tone on bare, unjacketed concentric cable because it tends to erode.

Utility 3: Have not heard much one way of the other. Losing the concentric neutrals is an issue.

Utility 4: Older cables with exposed concentric have contributed to the problems in locating the cables.

Utility 5: Everything new is jacketed.

Utility 6: We do have some corroded unjacketed cable due to flooding, salt, and weather conditions. I can imagine they would be hard to locate.

Utility 7: Our older cables are unjacketed. There might be issues identifying those. We now mainly install jacketed cables.

Are there other sources of mislocating? (e.g. water pipe)

Utility 1: Water and gas are examples as well as phone cable. They run both parallel and at angles to the abandoned wires. (“All of the above”)

Utility 2: Yes, we have experienced mislocating due to gas, telephone, fiber, and leftover lead jacket

Utility 4: Yes, water and communication lines.

Utility 5: Trouble with deep facilities at highway crossings. We sometimes put marker balls near the surface as a solution to this problem.

Have you had other issues related to cable locating?

Utility 1: Infrastructure improvements that are still grounded are a problem. It appears that tone bleeding is a larger problem when the ground is very saturated. We find that the abandoned bare concentric neutral is energized over anything else. The actual soil might be a problem. We have a lot of clay and not much rock. The problem is more common in the spring and the fall.

Utility 2: Our locating difficulty often comes from discerning which is the wire we are looking for [from non-abandoned utilities]. There is a lot of stuff in the ground. A small percentage of issues are from direct parallel circuits.

Utility 4: We have challenges during wet seasons and also very dry periods. Fault locating under pavement/concrete is a problem, too. Abandoned cables prolong outages during restoration events while ensuring the correct cable is marked/located.

What technologies are used to locate cables?

Utility 1: The standard is direct connection to the structure (at a transformer for example). Both active and passive modes are used. We don’t ourselves use ground penetrating radar, but other companies we own do. The ground penetrating radar doesn’t let us positively identify a specific utility – it only lets us know there is something there.

Utility 2: We have a locating wand. It has both active and passive modes.

Utility 4: Mostly passive and active. We rarely use ground penetrating, via a contractor.