This the multi-page printable view of this section. Click here to print.

Resources for Distribution Systems Research

- 1: Updates

- 1.1: 2022 Research Plans Available

- 1.2: 2024 Research Plans Available

- 1.3: Conversations with Experts - How Drone Research Evolved and What is Next

- 2: Applications

- 3: Capabilities

- 3.1: Lenox T&D Lab

- 3.2:

- 4: Distribution Area Quick Reference

- 5: Technical Leads

1 - Updates

The research team is happy to share our plans for next year’s R&D. Thanks to all of our utility advisors that have given input throughout the planning process. We are excited to continue working together!

Distribution resiliency research highlighted in the EPRI Journal

The EPRI journal recently published an article highlighting EPRI Distribution resiliency research and testing that we performed at the Lenox lab. This research was also recognized with an EPRI Technology Transfer Award in 2020.

Artificial intelligence research kicks off in distribution

Dexter Lewis has kicked off a research project focused on how to use imagery and AI to perform distribution inspection.

Urban Underground Event Scheduled

John Tripolitis leads the North American Dense Urban Utility Working Group each year. It is a great chance to interact with peers focused on urban underground distribution networks.

2021 Distribution Systems Overview published

Click here to get a preview of our research planned for 2021

New research begins to investigate new technologies for backup power for automation

Jason Anderson is leading a research project that is focused on reducing the largest O&M expense associated with distribution automation systems: batteries and backup power. Click here to read more

Conversations with Experts - How Drone Research Evolved and What is Next

Drones have moved into the mainstream, how did we get here, and where do we go from here? In this installment of our discussions with leaders in tech, we sat to learn more about how drones and drone R&D have evolved over the last several years.

1.1 - 2022 Research Plans Available

The research team is happy to share our plans for this year’s R&D. Thanks to all of our utility advisors that have given input throughout the planning process. We are excited to continue working together!

1.2 - 2024 Research Plans Available

The research team is happy to share our plans for this year’s R&D. Thanks to all of our utility advisors that have given input throughout the planning process. We are excited to continue working together!

1.3 - Conversations with Experts - How Drone Research Evolved and What is Next

In this installment of our discussions with leaders in tech, we sat to learn more about how drones and drone R&D have evolved over the last several years. This is a transcript of the conversation that has been edited for clarity and readability.

Have an idea for a future episode, or want to contribute? Email Drew McGuire (dmcguire@epri.com) with your ideas.

Podcast Transcript

Drew McGuire [00:00:05] : Hi, this is Drew McGuire at EPRI, thanks for joining me. Today, I want to sit down and learn more about EPRI’s research and the history of research into drones for the T&D industry.

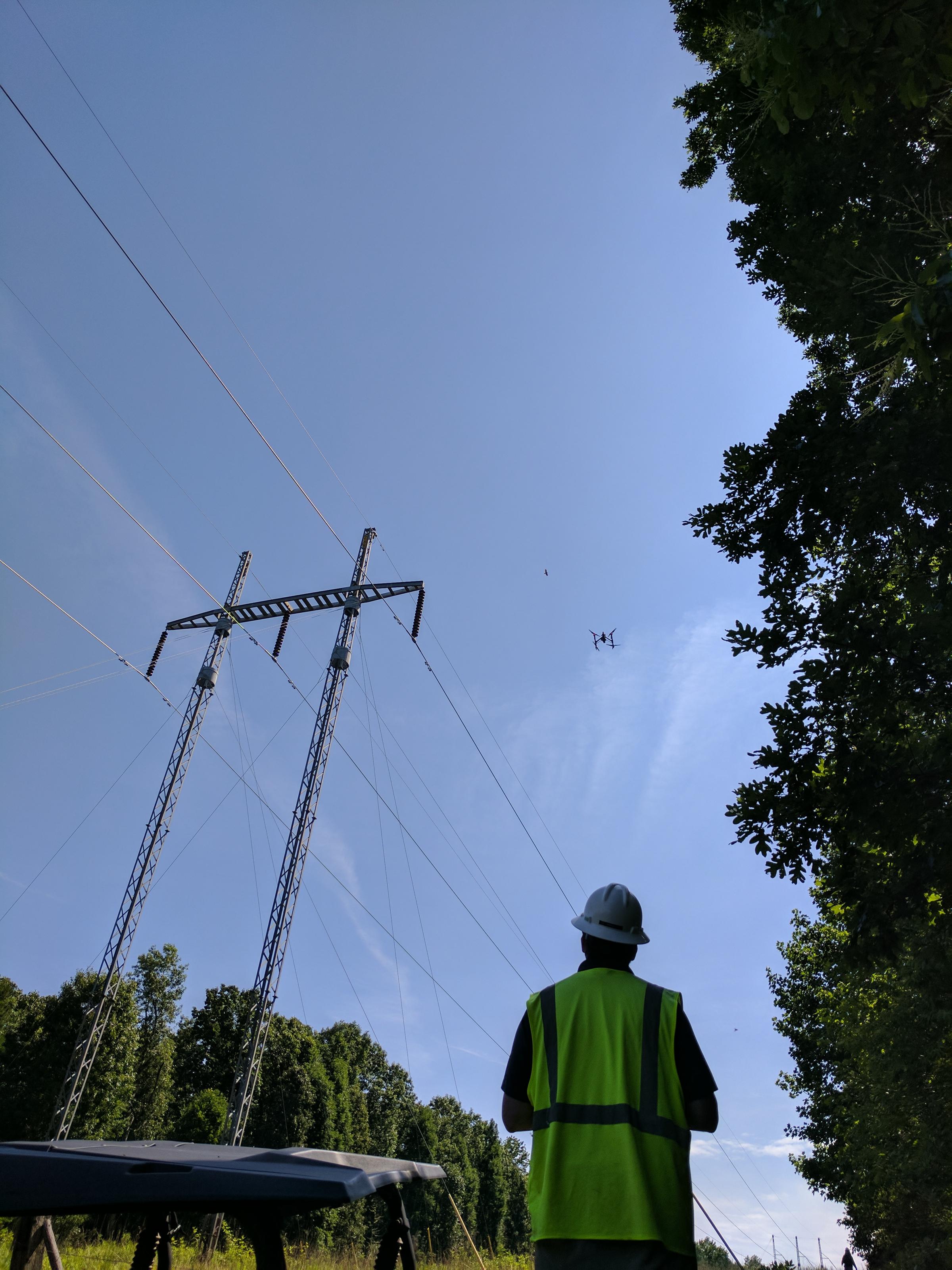

To help me with this, I’m going to sit down with Dexter Lewis. He’s part of the EPRI team. Many of you know Dexter, he has been around leading UAS research for several years. He’s known across the industry as one of the leaders in this space. So it should be an insightful conversation. To get things started, let’s just start from the very beginning.

Dexter, can you tell us why we started UAS research and what were we trying to accomplish in the beginning?

Dexter Lewis [00:00:40] : All right thank you Drew. Well, I’ll start by saying that EPRI’s first drone report was published 20 years ago in the year 2000. But it wasn’t until 2014 that things really took off. Around that time, low cost, high quality, easy to operate drones were emerging for the hobbyist and consumer market. Now, we recognize that a lot of T&D inspection work is done from the air using manned aircraft.

These aerial inspection methods have advantages over ground-based approaches, primarily in speed, but also introduce risks when operating that close to overhead infrastructure. Recognizing the risks of those traditional inspection processes, I guess EPRI and several leaders in the utility industry thought that drones could be an attractive replacement option. But in all honesty, we had more questions and unknowns than we did answers.

To answer your question about what we were trying to accomplish: at the simplest level, we were trying to perform a better inspection with drones. We were looking for improvements with drones over traditional methods: in terms of safety improvements, were they a cheaper inspection method, were they faster, or did they give us just an overall better quality of inspection? And I’ll say that these are fundamental questions we try to answer before we integrate any new technology or approach. And I believe EPRI was and still is in a unique position to help our members answer these questions through lab testing, real world field studies, and overall shared experiences.

Drew McGuire [00:02:33] : Yeah, I think you’re right. EPRI is at a unique position in the industry where we can see a pretty broad range of what’s going on and help work together to address the problems.

But the way you describe that, that’s a big, broad challenge that we’re facing here from the ground up, from consumer grade equipment all the way to deployed systems in utility environments. So how did you even get started? How did you approach this problem from the beginning?

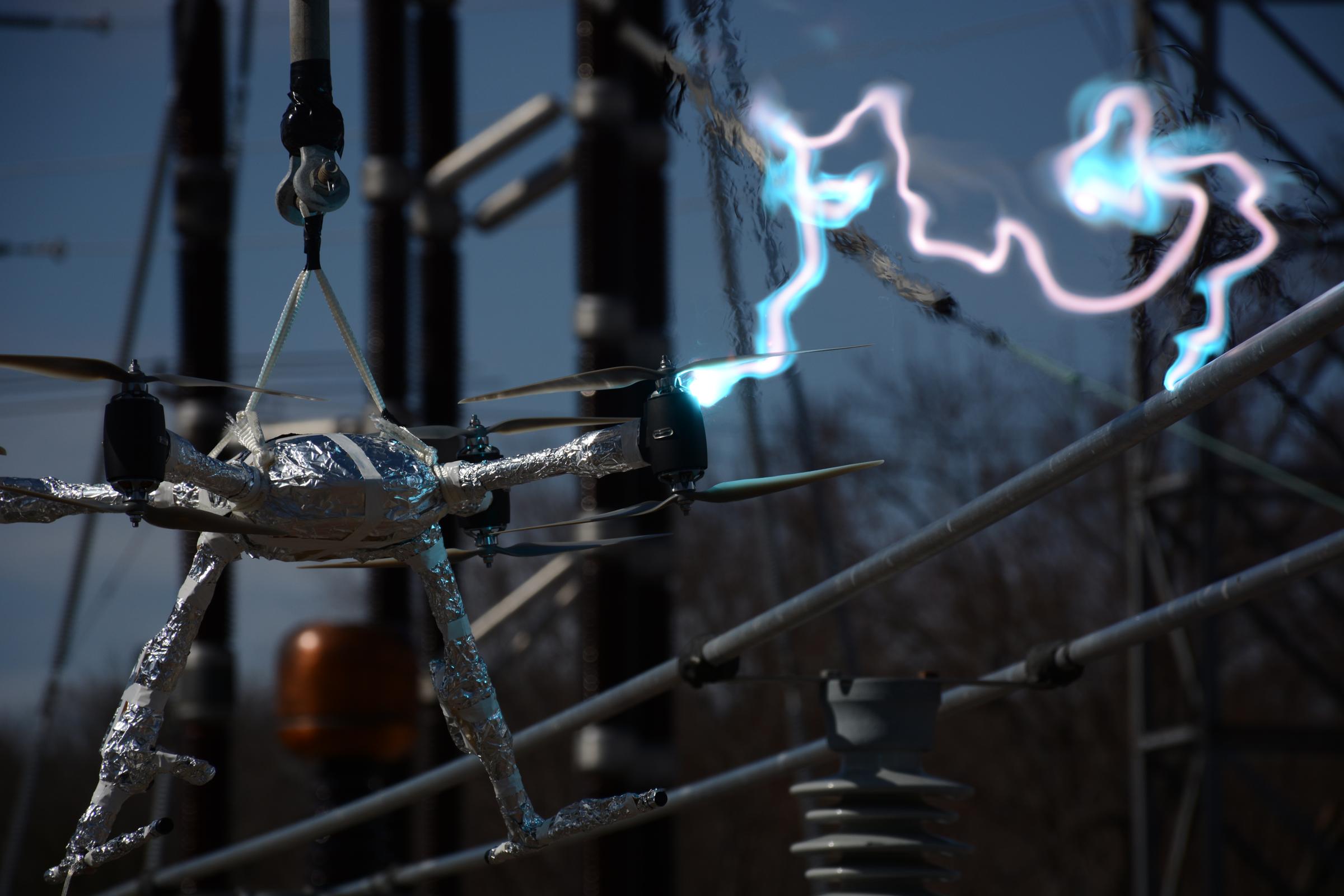

Dexter Lewis [00:03:00] : We started by building a team of interested utilities to begin a discussion. And a lot of our early engagements were focused on EPRI listening to our members. And it turns out that many utilities were asking the same questions. How does this drone technology work? How does it compare to our traditional or current methods and even things like how close can you fly a drone to a high voltage transmission line? How well do these things work in electromagnetic environment?

And I believe, you know, by listening to our members, we were able to really leverage our collaborative research model to target research projects that best answered these questions.

We started in our lab environment where we have the ability to test this technology safely and in a controlled manner. We still have projects where we do that. Then we moved into the field and at that time there was a ton of hype around the potential of the technology through listening to vendor presentations or service provider presentations or discussions.

There were a lot of anecdotal stories about how well this technology works, but not many documented scientific studies on the project. So we designed field tests where we compared drone inspections to manned aircraft inspections. We collected all kinds of data through this work where we really focused on trying to answer the question if drones can perform a better inspection.

I’d say fundamentally we did what we try to do with all our EPRI research. We try to provide our members knowledge based on nonbiased objective analysis to help them make informed decisions.

Drew McGuire [00:04:58] : That’s important because utilities have been making a lot of decisions around the technology in the last few years. It’s moved so quickly, you said we started back in the mid teens. Just in a few years we’ve made a lot of progress, and the landscape has changed so much around drones since then. There’s the new regulations, the technology has changed quickly, and utilities have really established drone programs by this point, in many cases.

You just described a lot of work that you’ve done so far. Can you summarize some of the key takeaways that you found?

Dexter Lewis [00:05:35] : I’ll start by saying that not all drones behave predictively in energized environments, testing in a controlled environment first can really help lower your risk before deploying on a real line. Also, drone inspection costs in the beginning were significantly more than inspection costs for traditional methods. If you look on a cost per mile basis. We’re still looking for ways to make that process more efficient.

One of those ways is through automation. Automation can help improve your inspection efficiency, but usually translates into more work on the back end in terms of reviewing your imagery.

You really need a way to efficiently handle the amount of imagery that these drones can collect, especially if they’re operating autonomously.

And finally, I’ll say that just giving a drone to an inspector or a field employee doesn’t always translate to a more efficient process. We learned you need to be smart about how you deploy this new aerial functionality to really capture all the value that it can provide.

Drew McGuire [00:06:55] : A lot of the unknowns that you discussed earlier are knowns now. We’ve answered those already, or at least we’ve begun to understand some of them. With that in mind, what does the future look like around drone research? What’s coming up next?

Dexter Lewis [00:07:06] : I suppose I’ll say that drones have made it through the hype cycle. They are tools that are here to stay and that are providing value to utilities today. However, I also think there is a lot of work that still needs to happen before we can fully realize the potential of this technology.

You mentioned how things have changed and continue to change. You know, the technology, the regulations, and the applications are evolving so fast. And it seems like a totally new landscape every six months. But we still can’t operate our drones long distances due to line of sight restrictions. And even if we could, we may likely be limited by our flight time or our wireless link limit.

And that’s a really big deal for our industry because we have so much linear infrastructure. A lot of our ongoing and future research is focused on being ready to take advantage of those beyond visual line of sight operations whenever they can be performed safely, and researching how best to deploy our drones in our current and future environment.

And kind of hinting at that, a lot of the work that we’re doing is focused on making our drone inspections more efficient through automation. There’s no doubt that drones can fly autonomously around the structure to capture imagery to perform an inspection. However, it’s really important that we understand when we’re leveraging those automated inspections that we’re getting the right picture to do a sufficient inspection.

We can’t jeopardize inspection quality for efficiency, and we have a project focused on that, where we’re trying to identify these data capture specifications to build confidence in these automated inspection models.

Now, through these automated inspections, a lot of times they generate a whole bunch of imagery and data. And the question is, what do you do with it? Because we don’t want to be building efficiencies on our data collection process, but then spending a lot of time reviewing imagery and data in the back office.

So drones have been a big driver in our push into artificial intelligence and image processing research. This is an area that we’ll be engaged with for many years to come.

It is also easy to think about the positive uses of drones, but they could also pose a threat or challenge to our industry. There are some unknowns related to the physical and cyber aspects of this technology. So how can we protect our infrastructure from malicious drone actors? And how can we be confident that the drones we’re using have adequate cybersecurity protections in place? We have active research in these areas as well.

In summary, there has been so much work from EPRI and the utilities over the last few years. This technology can really change the way that we as an industry perform work. And it’s exciting to think about what we will be able to accomplish in the future.

Drew McGuire [00:10:25] : Thanks, Dexter. I think that’s a really interesting way to see how we’ve started from the beginning of this research and where we are now and what’s coming up next. It’s good to back away from it sometimes and see the big picture. Thanks for walking us through it today.

So if you’re listening to this and have more questions, you can reach out and talk to Dexter at any point. Shoot him an email at dlewis@epri.com, or you can get in touch with me via email as well, dmcguire@epri.com.

If you have questions, feel free to reach out. Thanks for joining us today and we’ll talk with you later. Thank you.

2.1 - Reduce Outages by Designing Better Structures

Lab testing is a critical step to improve resiliency

One of the best ways to understand how a structure performs is to see it in action. Normally, this would require you to be in the field when a tree or branch falls on a line. EPRI’s laboratories are able to perform this test safely, repeatably, and with full data and imagery collection.

The purpose-built test site at EPRI’s High Voltage laboratory in Lenox, Massachusetts gives utility designers and engineers the ability to see their designs in action and identify opportunities to improve the design in real-time. The researchers construct full-scale structures built to your specifications, then subject the structure to the impact of a mid-span tree-strike or falling branches. Sensors and cameras capture the action so that the test team can analyze performance and identify design changes that could improve performance.

Major weather events necessitate improved resiliency and reduced restoration time. EPRI collected data to identify time consuming restoration tasks. Replacing broken poles was, by far, the most time-consuming task

Design characteristics to improve through testing

EPRI can test multiple characteristics of designs and components. Two of the main objectives of the testing are to reduce restoration time by pole saving and increasing reliability through branch deflection.

Pole Saving

EPRI’s resiliency research results have shown that a key to reducing restoration time is predictable and consistent structure performance during storms. Put simply, it is important to know the order in which components will fail, and it is important that the pole itself is not the first component on that list.

One approach is to apply the concept of mechanical coordination to your designs. Coordination is well understood in power system protection, and the same concept can apply in structure performance. Unlike protection system coordination, however, structures are made up of physical components with unknown or unpredictable performance characteristics. This makes it very difficult to model or simulate structural performance.

EPRI’s resiliency research results have shown predictable and consistent structure performance is key to reducing restoration time after storms. Put simply, it is important to know the order in which components will fail and that the pole itself is not the first component on that list.

The Test Site

Explore the test site by hovering over the green highlighted areas.

How it works

Watch a virtual tour of the test site with EPRI Project Manager Joe Potvin below.

The EPRI test site is designed with the flexibility to meet your needs. We have tested many types and sizes of structures. Call us to talk about how we test your structure!

Utilities use the full-scale test facility to assess potential resilient design improvements. The failure mode of this structure was typically a broken pole. Testing demonstrated the need for an improved design.

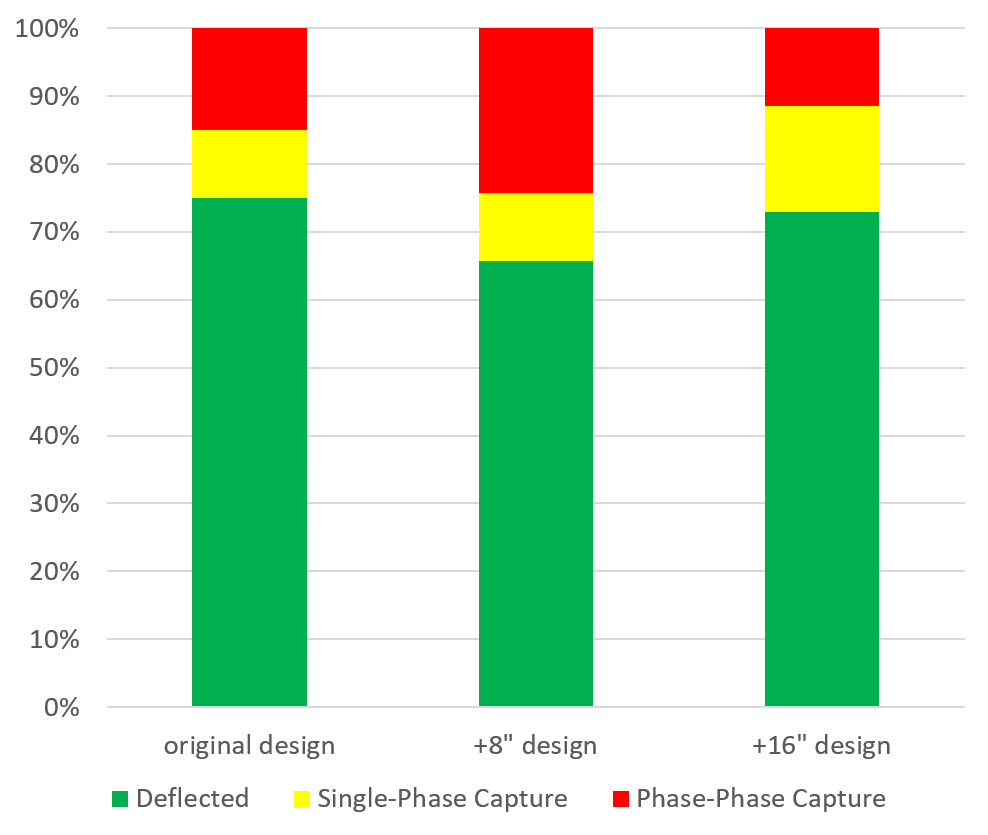

Branch Deflecting

Fallen tree branches cause many outages, often by getting stuck on the line and creating an electrical fault. This test helps identify conductor configurations that are less likely to cause reliability issues when branches fall on them. Testing includes multiple combinations os configurations, as well as branch species and types that are representative of your utility’s service territory.What if we could identify conductor configurations that branches are less likely to get caught on?

EPRI can simulate fallen branches on overhead lines by literally dropping branches from above. However, this requires careful consideration of representative tree species, review of outage data, and discussions with utility vegetation experts.

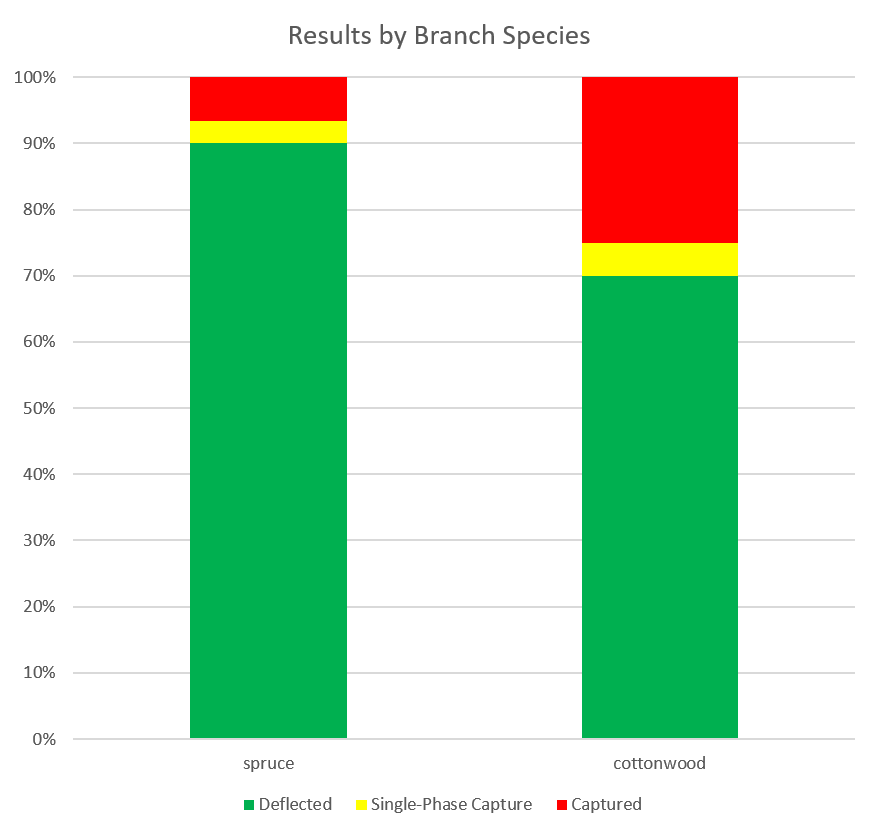

Branch deflection vs capture depends on many factors, including branch shape, line configuration, and how the branch contacts the line. The results rely on many individual tests to generate statistics.

Results can also demonstrate branch species that may be more problematic and require more management.

How to get involved

If you would like to schedule testing of your designs, please contact our research leader, Joe Potvin, at jpotvin@epri.com.

Find more information here.

2.2 - EPRI T&D Asset Forensics & Failure Analysis

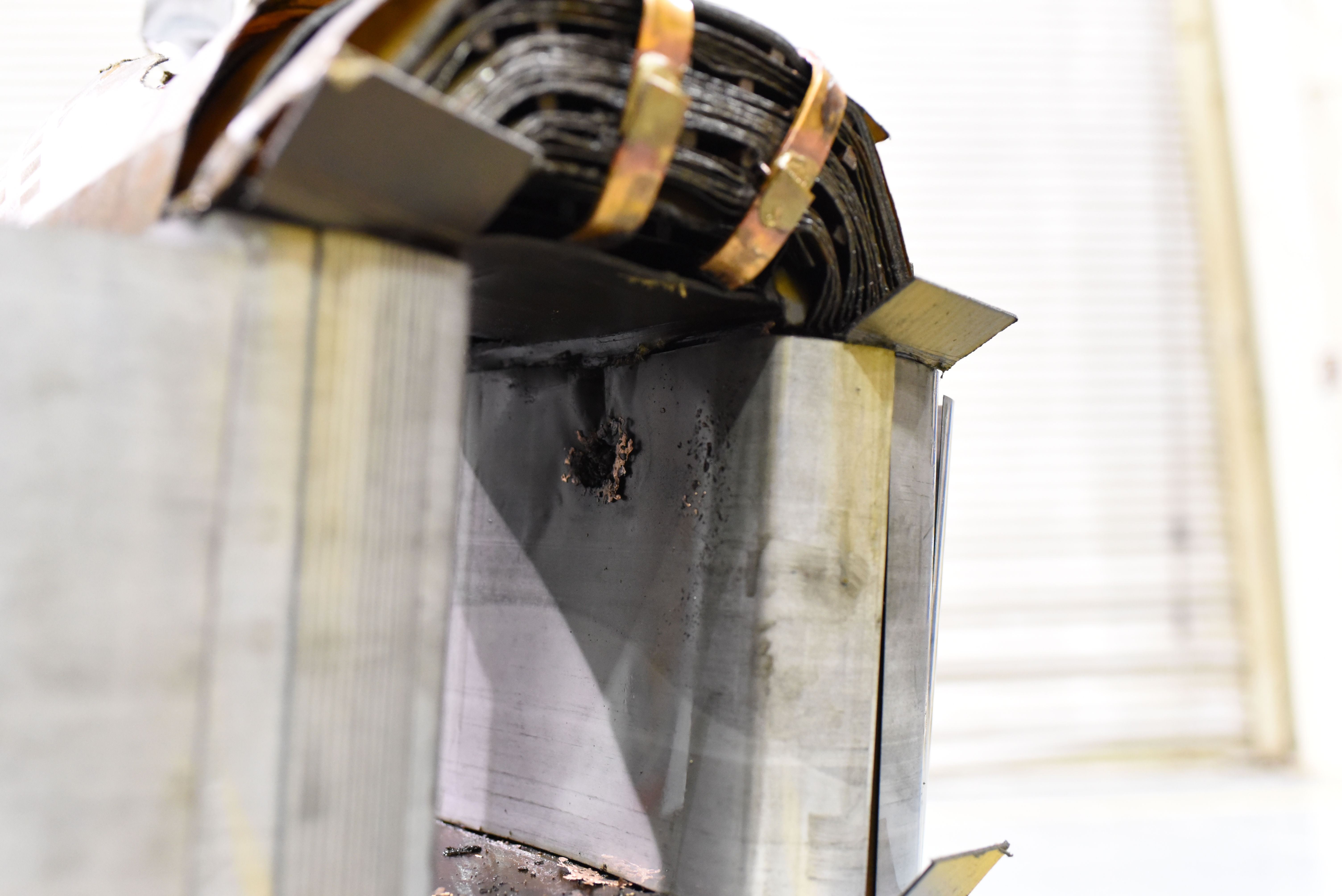

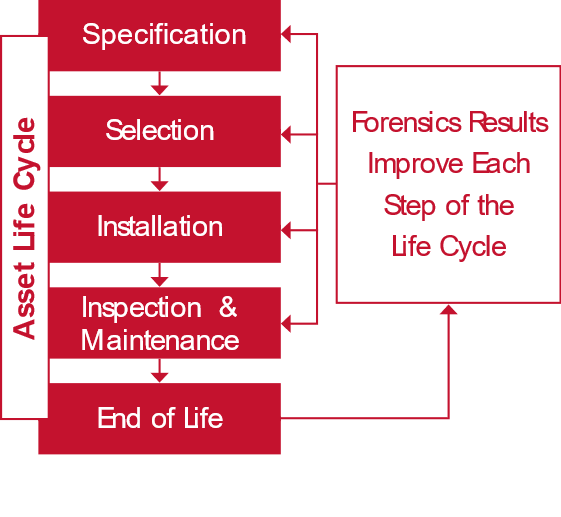

Transmission and Distribution (T&D) asset failures can significantly impact system operation, reliability, and safety. These failures are frequently difficult or impossible to predict, and they can sometimes seem random. In reality, these failures are driven by degradation mechanisms and stressors that lead to specific failure modes. Even sophisticated online monitoring data may not tell the whole story. A forensic analysis may be the best opportunity to learn why a component failed. This helps you prepare for the future by improving specifications, inspections, or maintenance practice.

Use the Past to Improve the Future

The pace of utility operations is fast – especially when you are responding to an equipment failure. By using the EPRI team to perform a forensic analysis, you not only free your team to focus on the critical work of preparing for the future, but you are also equipping them with lessons from the past. Learning from past failures gives you new insights so that you can:

- Improve specifications – Whether it is a design issue, a materials issue, or an environmental issue, there may be an opportunity to prevent future failures by updating your specifications based on causes of previous failures.

- Improve work practices – Workmanship issues during installation, operations, and maintenance are difficult to diagnose and correct without data from a forensic analysis.

- Improve inspection capabilities – A forensic analysis is a critical step in understanding how assets age and fail. This information directly informs inspection tools and practices that can improve performances.

The Forensics Process

A proper forensic analysis of a transmission or distribution component is a multi-disciplinary exercise that requires deep expertise across a broad range of engineering and material science. While each investigation is unique, EPRI applies a rigorous, scientific method that can include a multitude of approaches such as:

- Materials analysis – Even simple components can be made of complex materials with unique performance characteristics. A thorough analysis of each material not only increases understanding of the component itself, it can also expose byproducts produced during failure.

- Mechanical & Electrical Testing – Depending on the component, a series of mechanical & electrical tests can begin to identify and locate the point of failure.

- Detailed dissection – In many cases, a thorough and methodical dissection of the failed component can expose evidence of design, manufacturing, or installation errors. It takes time, dedication, and an eye for detail, but the effort is typically worthwhile.

Expertise

EPRI engineers test and analyze T&D assets every day. The team has decades of experience in understanding asset design, performance, degradation, and failure. We have experts across many assets and scientific disciplines, such as transformers, circuit breakers, connectors, corrosion, underground equipment, and distribution automation. This expertise, coupled with the EPRI labs, means that the team can perform the forensic analysis, and put the results into context to help you understand how to turn the insights into action.

Examples of T&D Asset Forensics & Failure Analysis

Tools and Capabilities

The EPRI laboratories can analyze a wide range of components and assets. We have a vast array of advanced inspection and analytical tools at our disposal, such as:

- Stereo microscope

- Scanning electron microscope

- Sectioning and dissection equipment

- Partial discharge test equipment

- Gas chromatograph – Mass spectrometry

- Energy-dispersive X-ray spectroscopy

- Materials hardness mapping

- X-ray scanning and imaging

Example of a transformer that failed in-service. The failure event was detected by an online diagnostic system, but the detection could not be classified for action. The forensic analysis identified the root cause, which strengthens the future effectiveness of the online diagnostic.

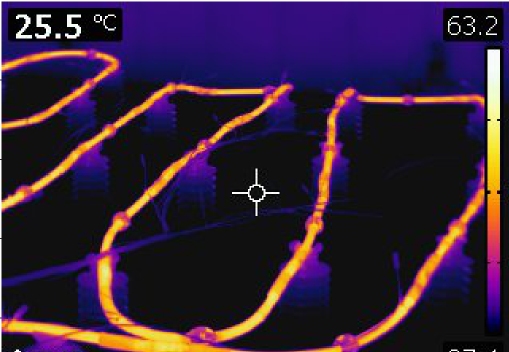

Surge arresters were found to be heating in service, but the utility did not have a clear replacement criteria. The forensic analysis showed that the heating was likely due to design and material selection and that continued heating would cause further degradation. As a result, the utility had confidence to quickly remove heating arresters from service.

Distribution switches were found to be heating in the field. A forensic analysis identified corrosion at the contact points that was the cause of the localized heating. Further analysis identified a design issue as the root cause, leading to improved utility specifications to prevent this issue in the future.

Why EPRI?

The EPRI team is known for deep technical expertise that is applied to practical problems. Our engineers are passionate about understanding asset performance and failure and using those results to help improve power system performance. We take pride in high-quality results and are committed to technical excellence. EPRI has earned a reputation for objectivity, meaning that you get results that you can count on from the team that you trust.

3 - Capabilities

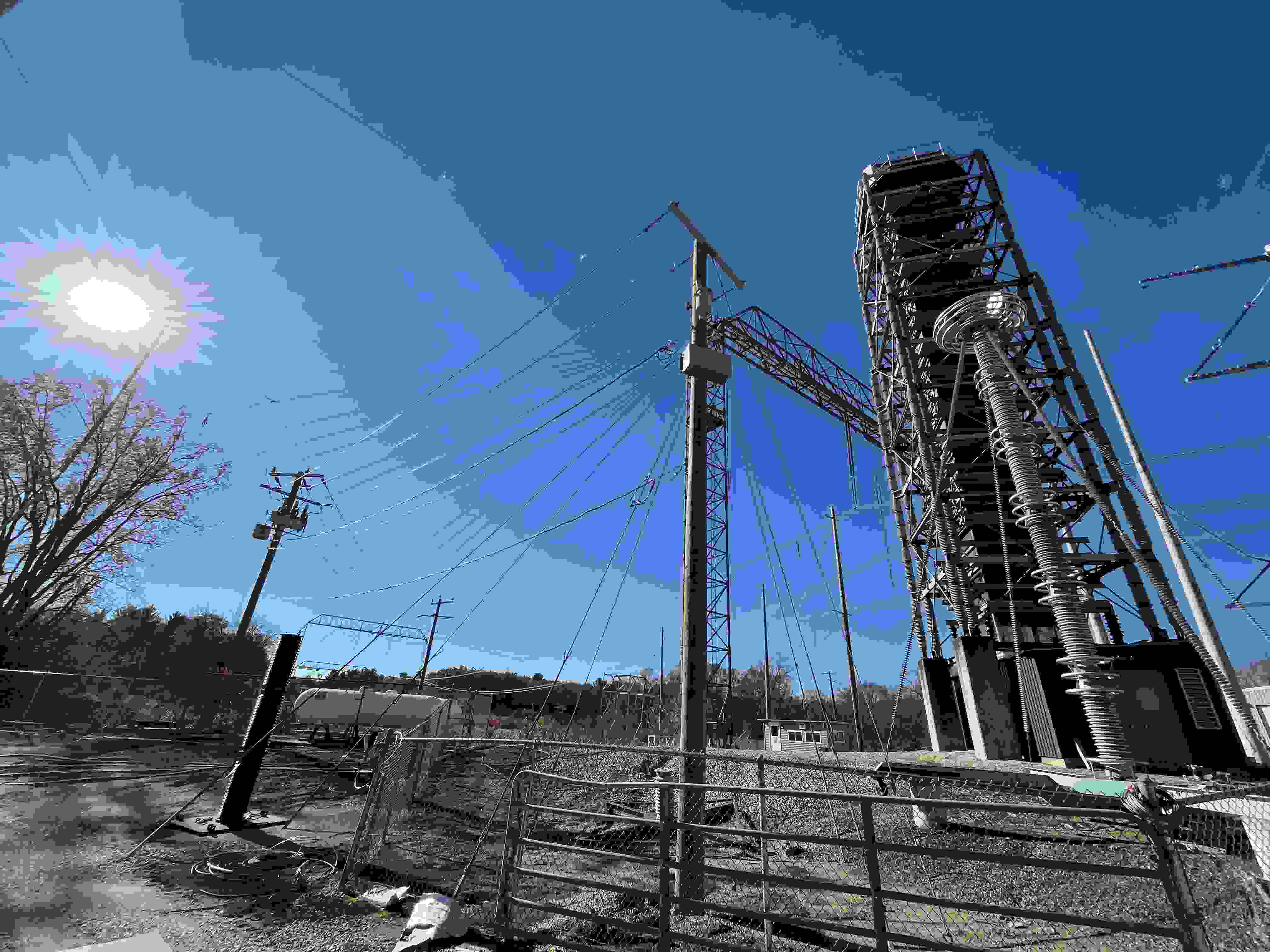

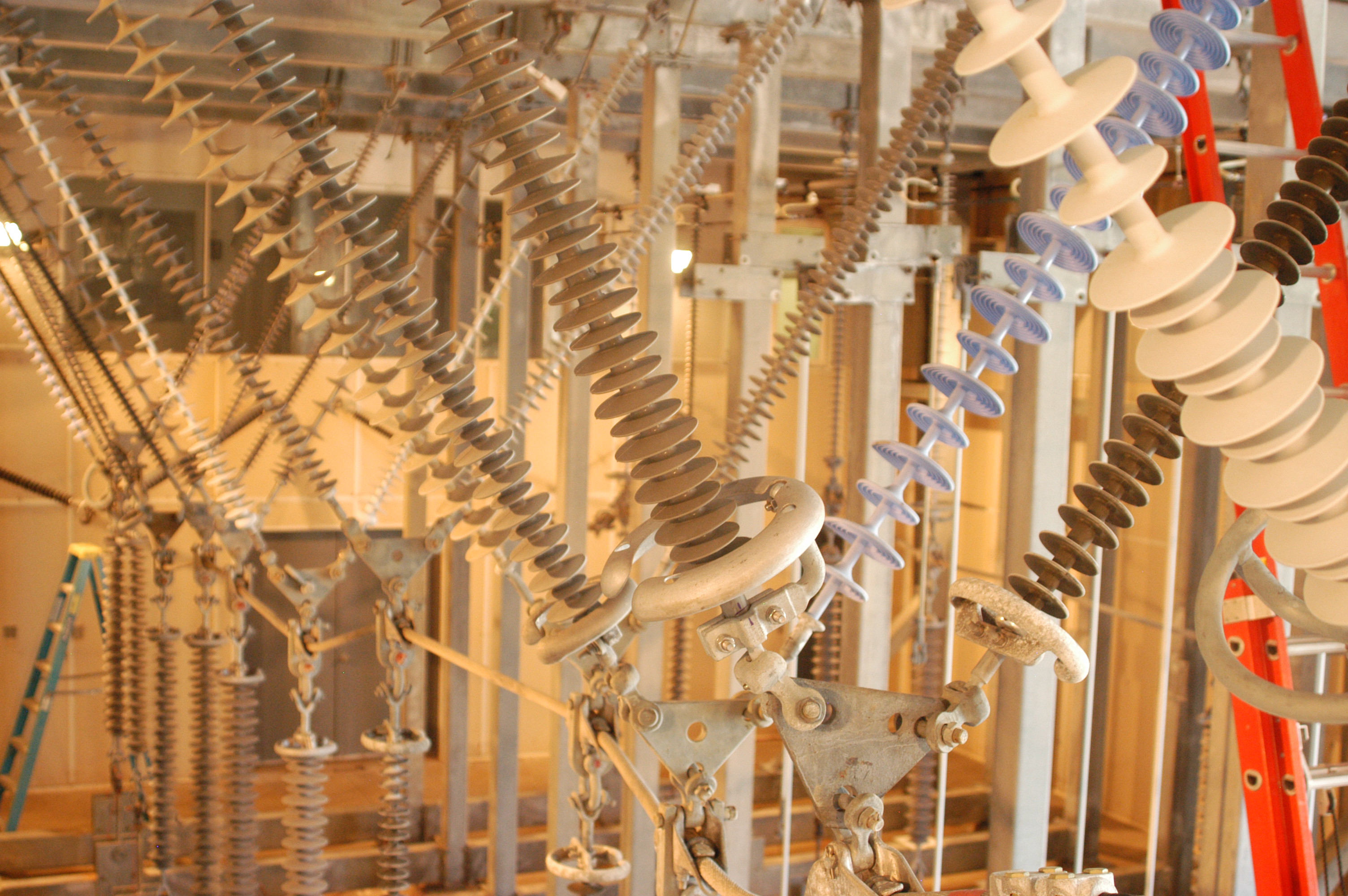

3.1 - Lenox T&D Lab

The Transmission & Distribution laboratory in Lenox, MA provides a unique test facility for a variety of T&D research topics. Explore the laboratory below by clicking the popover (red dots) at a selection for the test sites. Click the popover to keep the popover open.

- Arc Flash

- Burndown of bare and covered conductors

- Flammability of equipment under fault condition

- Damage to crossarms and insulators under fault conditions

- Performance of sensors during faults

- Grounding and stray voltages; step and touch voltages during faults

- Evaluation of vegetation faults

- Fuse cutout and single-phase recloser performance

- Conductor slap

The test fixture applies a three-point bending test to composite crossarms. This test includes the capability to enclose the crossarm and elevate the temperature to investigate load-deflection characteristics in extreme heat.

Outdoor DA test area for long term testing of automation components, to understand the performance overtime.

Lightning and grounding testing up to 800kV to improve distribution automation equipment reliability.

Three phase accuracy test set is used for testing distribution sensors and can be energized at 19.2kV with current from 0A to 600A.

This facility is an MV and LV test area and an outdoor aging yard for distribution assets.

EPRI can configure this multi-purpose test area to perform cantilever pole strength testing. This testing is helping utilities learn more about the quality of pole inspection by comparing field assessment with actual remaining pole strength as determined through laboratory testing.

The energized-downed-conductor area has been used to record signatures of live, downed conductors. Several relay and recloser technologies for detecting these high-impedance faults have been tested. Multiple scenarios are available, including multiple voltages and different surfaces.

This capability has also been used to evaluate vehicle grounding and what happens when a vehicle becomes energized. This includes step and touch voltages around energized vehicles.

This capability has also been used to evaluate vehicle grounding and what happens when a vehicle becomes energized. This includes step and touch voltages around energized vehicles.

Three phase reconfigurable transmission line more than 500 meters long.

Three impulse generators are located in the EPRI Lenox laboratory, the largest of which is the 5.6MV tower which simulates lighting and switching surges for performing component testing and insulation coordination mapping.

Resiliency & reliability testing of full scale distribution structures using simulated tree-strikes and falling branches.

Research substation to investigate component, monitoring, and diagnostic performance.

Drone test site to understand aircraft and payload performance in electric environments.

Long-term test fixture to understand degradation and inspection methods for low voltage connectors.

Accelerated environmental aging is performed on full scale composite (fiberglass) poles and crossarms as well as small scale samples to determine changes in their mechanical and electrical properties.

Test Facility designed to replicate user defined human and animal perceptible shock scenarios. This includes ability to simulate concerns associated with urban shock hazards, overhead distribution stray voltages and swimming pool electric shock concerns.

EPRI has the capability of performing tests on transmission line insulators with guidance from ANSI C29.2B Section 8.3.4 –“Combined mechanical and electrical strength tests”

The accelerated aging chamber is 40 ft wide × 60 ft long × 20 ft high. A computer-controlled environmental system simulates a defined climate inside the aging chamber by varying temperature, clean fog, salt fog, clean rain, UV radiation, and humidity.

Hover over these links to locate a test site on the map above:

Arc fault tests | Arc flash | DA Full-Scale Test Area | Composite Structure Aging | Composite Crossarm Test Area | MLV Yard | Stray and Contact Voltage Test Infrastructure | Distribution Automation Loop | MV Termination Cable Testing | Pole Strength Testing | Full-scale Structure Tests | Energized Downed Conductor | Vehicle Grounding | 23-kV loop | Reconfigurable Transmission Line | DA Lightning & Grounding | 5.6MV Impulse Generator | Drone Test Yard | 138kV Test Substation | Above Ground Test Vaults | Underground Explosions Tests | Low Voltage Connectors | MTS M&E | Aging Chamber | New 12 stage IG

3.2 -

4 - Distribution Area Quick Reference

Electric Power Research Institute (EPRI): Conducts research, development, and demonstration (RD&D) projects for the benefit of the public in the United States and internationally. As an independent, nonprofit organization for public interest energy and environmental research, we focus on electricity generation, delivery, and use in collaboration with the electricity sector, its stakeholders and others to enhance the quality of life by making electric power safe, reliable, affordable, and environmentally responsible.

In November 1965, the Great Northeastern Blackout left 30 million people in the United States without electricity, starkly demonstrating the nation’s growing dependence on electricity and vulnerability to its loss. It marked a watershed for the U.S. electricity sector and triggered the creation of EPRI. Since 1972, EPRI has collaborated with the electricity sector and its stakeholders such that our membership has grown to represent approximately 90% of the electric utility revenue generated in the United States and extends to participation in more than 35 countries.

EPRI’s Distribution Area programs conduct research, development, and demonstrations that provide the technical basis and tools to support the planning, design, construction, maintenance, operation, and analysis of the distribution system. Program structure and content provides the template for how EPRI coordinates and executes on research efforts. Each area program provides a unique perspective. Together, they address the challenges that distribution system owners face today and help prepare them with the tools and capabilities needed for transformation to a modern grid. This research further supports EPRI’s mission to provide a Safe, Reliable, Affordable and Environmentally Responsible source of electric power for society.

Programs and Projects

Programs

What Distribution Area Programs include: Distribution Systems (P180), Integration of Distributed Energy Resources (P174), and Distribution Operations and Planning (P200).

Who Area Program Managers and technical staff execute research and manage the projects. Supporting members advise and collaborate on research, serve as host sites, and provide input on real world research needs.

How Programs consist of individual projects in which utilities participate through annual funding and collaboration. Funders are provided no-cost access to project deliverables which are released for a particular year (or years) of funding.

When Programs are ongoing research efforts. EPRI, in collaboration with program funders, determines the most important research needs to be handled in current-year projects. A project may take one or more year to complete.

Annual Research Portfolio (ARP)

Also referred to as Base Funded or Membership.

What Distribution ARP programs are groups of projects that address related research topics and are offered to members on an annual basis. Projects generally are multi-year efforts, are of interest to a large number of utilities, and address significant industry issues (e.g., asset inspection and maintenance, asset analytics, safety, DER impact and value, planning, and protection).

Who EPRI subject matter experts (SMEs) and leadership collaborate with members to chart the direction of the ARP and identify projects based on system experiences, present trends, existing roadmaps, and other ancillary information. EPRI SMEs, augmented by world-class contractors, conduct the research. Participating members serve as technical advisors to the projects.

How The following year ARP is published in June. Companies may join entire programs, individual projects or project sets (groups of related projects). During the year, research is performed and deliverables are created for members which have funded the research. Typically, EPRI owns the research results and provides an internal use license for the deliverables to funders. The cost to join Distribution ARP projects is based on the utility’s prior year distribution annual GWh delivered. Annual ARP selections are made using the Research Portfolio Agreement (RPA).

When Members can join an ARP offering at any time during the year up until December 31. Deliverables, and other forms of technology transfer, are provided throughout the year, but most are delivered near the end of the year.

Technology Innovation (TI) Program

What TI program and projects generally have longer-term goals and have higher research risks. Learnings from TI projects can inform and inspire future ARP projects and provide thought leadership for EPRI members, society, and other stakeholders.

Who The TI program is managed by a separate team, including the process for prioritization of projects and allocation of funding. EPRI technical staff execute the projects. The TI program is advised by EPRI’s Research Advisory Committee (RAC), comprised of senior management of EPRI members.

How Twelve percent of ARP funding is allocated to the TI program. An internal process is used to allocate funding. All TI deliverables in a given year are available to all EPRI members investing in an EPRI research program in that year.

When Funding is allocated on an annual basis.

Supplemental Projects

Includes Tailored Collaboration (TC), Self-directed Funding (SDF), and Co-Funding Projects

What Supplemental projects address specific issues that may be of interest to a group of members or a single member. Projects may involve research, demonstration or implementation of advanced tools, technologies, or technology transfer. If a supplemental project has multiple funders, the scope is identical for all participants. Typically, EPRI owns the research results and provides funders an internal use license for the project deliverables. Research results may be further developed by EPRI in other projects.

Who Area Program Managers and technical staff conduct the research. Participating members designate a technical advisor to lead their collaboration in the project, including serving as a host site and/or providing examples, experience, and data.

How The EPRI technical staff and project funders agree upon a statement of work (SOW) defining the scope, schedule, and deliverables. Companies join the project through revenue agreement, which usually adopts pre-determined terms and conditions in a master agreement between EPRI and the funder. ARP Funders can join using SDF, TC funding, or co-funding (see below). Project funders receive the project deliverable(s) at no additional charge. Others who did not fund the project, but desire access to the deliverables, must purchase or license the priced deliverable(s).

When Supplemental projects can be initiated at any time during the year and can be initiated quickly. Deliverables are generally delivered on the schedule identified in the SOW. Supplemental projects may be multi-year.

Supplemental Funding Types

Self-Directed Funding (SDF), Tailored Collaboration Funding (TC), and Co-Funding

What Twenty-five percent of a member’s ARP funding is allocated to either an SDF or TC account or pool that can be used by the funder to join supplemental projects. Projects must meet criteria defined in the Supplemental Funding Policy document found on the EPRI Member Center website.

- Self-Directed Funding (SDF): Pooled SDF funds can be used entirely to participate in a supplemental project or joined with co-funding (see below).

- Tailored Collaboration Funding (TC): Pooled TC funding must be matched by the funder with an equal amount of co-funding to participate in a supplemental project. TC plus the matching co-funding may also be combined with additional co-funding (see below).

- Co-funding: Funding provided directly from a utility through an invoicing process. Members may join supplemental projects using entirely co-funding, or using a combination of co-funding and SDF (or TC) funding.

Who The SDF or TC account is usually managed by the member’s Manager of EPRI Technology Transfer (METT). Participating companies decide whether to have TC (see below) or SDF funding when they submit their ARP selections each year.

How Funding is transferred from the SDF or TC pools to a supplemental project using a revenue agreement, including a statement of work. Where co-funding is involved, the revenue agreement includes invoicing terms. Participation using TC, SDF, or co-funding can be initiated via an online tool or through discussion with EPRI staff.

When Funding in the TC or SDF pool must be committed to a project under written contract by the end of the year in which it is generated or the funds lapse.

Billable Service Agreement (BSA)

What A BSA is available for EPRI to do services work. A BSA is used for specific results that can solve an issue or specific problem without limiting EPRI from performing the same approach, idea, or concept for other funders. Typically, if the deliverable is a report, that report is “owned” by the funder, but EPRI owns the background technology and any improvements to the background technology which occur during the contract period. Billable Services are generally not eligible for TC or SDF. There can be limits on the types of services work which EPRI can undertake. For example, EPRI does not provide expert witness services in court cases. These limitations are guided by EPRI’s tax exempt status and independence requirements. The total amount of BSA-related work that EPRI performs, in aggregate, is limited by EPRI’s non-profit tax status because it does not meet the public benefit research criteria.

Who Area Program Managers and technical staff work with the requesting organization to agree upon a statement of work defining the scope, schedule, and deliverables.

How Funding is transferred to a BSA project using a revenue agreement which includes invoicing terms and a SOW. Terms and conditions are often incorporated from a master agreement in place between EPRI and the funder. A BSA is initiated by discussions with EPRI staff.

When A BSA can be executed at any time during the year.

Master Agreement

What Almost all members have a master agreement in place setting out the terms and conditions for most projects involving EPRI and the member. Pre-negotiating terms such as confidentiality requirements, export control, and licensing requirements, means that supplemental projects can be easy to initiate once the SOW and member funding sources (e.g. SDF or co-funding) are determined. There are limited occasions where a vendor involvement, government funding, or special project needs, leads to additional terms (e.g. special host utility access requirements for those working on, or visiting its site).

Who The master agreement is usually negotiated, agreed upon, and signed by the legal departments and management of the member and EPRI.

How The master agreement is referenced in the RPA, in supplemental agreements (SDF, TC, co-funding), and in BSAs.

When The master agreement is typically in place for a longer duration; recent agreements have had a duration of 10 years.

Delivery of Results

What EPRI research deliverables may include technical reports, technical updates, software, workshops, hardware demonstrations, field guides, and reference manuals, each released with product identification (PID) numbers. BSA deliverables are an exception and do not have PIDs.

Who Companies that join specific ARP or supplemental projects receive an internal use license and access to the deliverables from that project at no additional charge under the terms of their agreement. For ARP, the funding for the program/ project must be provided in the year of release for the funder to receive access at no additional charge. Typically, companies that did not fund the specific project can license or purchase a specific deliverable provided they meet all licensing and export control requirements (license & export checks for funders occur at the contract stage). BSA deliverables are usually not available for purchase by others.

How EPRI deliverables from ARP and supplemental projects are stored and available for download from EPRI’s Member Center (membercenter.epri.com). Typically, only eligible users can download specific EPRI deliverables for no additional fee, based upon which programs and projects they have joined. Some project deliverables (webcasts, conference call updates) are not available to non-funders.

When Most ARP deliverables are provided at the end of the year. Supplemental deliverables are provided as defined in the project’s SOW.

Existing Product Credits

What In exchange for a minimum, multi-year commitment at a mutually agreed level and type, EPRI provides credits for members to use towards the purchase or license of existing EPRI deliverables for which a member would otherwise not be eligible (for example, where a member did not fund the work producing the deliverable).

Who The Product Credit Pool is usually managed by the METT at each utility.

How Participant SMEs engage their company’s METT to request that Product Credits are used to gain access to a specific EPRI deliverable. When Product Credits may be used at any time during the multi-year agreement. The product Credit Pool expires at the end of the multi-year agreement.

Advisory

Distribution Sector Council (DSC)

What The DSC provides executive level advice to the Distribution area. The DSC is regularly briefed on ongoing RD&D progress and provide strategic guidance on technical issues, research areas, and EPRI business operational areas for improvement. The DSC is a subset of the Power Delivery & Utilization (PDU) Sector Council, which also includes the Transmission, Energy Utilization, and Information Communication & Cyber Security (ICCS) areas.

Who DSC positions are generally filled by executives from EPRI’s members.

How During PDU and DSC meetings, EPRI staff and members make presentations and roundtable discussions follow.

When Sector Council meets twice each year (winter and fall) on the Wednesday and Thursday following the Distribution area advisory meetings.

Distribution Executive Committees (DEC)

What The DEC advises the EPRI Distribution Sector leadership and collaborates with EPRI to develop the DSC agendas.

Who The DEC is comprised of a subset of executives from the DSC and is led by the DSC Chair and EPRI DSC Leader.

How The DEC communicates through webcasts, face-to-face meetings, and surveys.

When Webcasts are held on an as-needed basis. Breakfast meetings are usually held on the Thursday morning of the Sector Council Meeting.

Distribution Advisory Groups

What The Distribution advisory groups provide guidance to the research areas and are: 1) made aware of R&D progress; 2) share member practices including use of EPRI research results; 3) share utility experiences that can help inform EPRI’s research programs; 4) advise R&D roadmaps; and 5) identify EPRI business operational areas for improvement.

Who Members are often directors/managers from member utilities, led by the EPRI Distribution Area Program Managers and technical staff and the program chair.

How Each Distribution program has its own advisory meeting, and sometimes meets jointly with other programs to enhance collaboration. Presentations are made by EPRI staff and member utilities with roundtable discussions following.

When Distribution advisory groups meet with other PDU Advisory Groups twice each year (winter and fall) on Monday through Wednesday (midday). Distribution advisors may also participate through project task forces, which generally meet three times per year, to advise projects, or through topical technical webcasts that are held throughout the year (see Research Area Operational Calendar graphic).

Distribution Task Forces (TF)

What Task Forces advise groups of ARP projects based on technical area (see Advisory graphic). TFs are made aware of R&D progress and results in their areas of funding, collaborate on ongoing research, identify new research areas, and provide a forum for members to share research applications and utility operational experiences.

Who Task Forces are generally staffed by the SMEs assigned by member utilities to advise each ARP project. TFs are led by EPRI technical staff together with a utility TF leadership team.

How Presentations are made by EPRI staff and member utilities followed by roundtable discussions. TF presentations often focus on enabling member application of R&D results.

When The TFs generally meet three times per year, by webcast or otherwise, to update the TF on progress (see Research Area Operational Calendar graphic).

5 - Technical Leads

Program 180 Technical Contacts

| Topic |

Contact |

|

|---|---|---|

| Program Manager |

Joe Potvin |

|

| Technical Assistant III |

Eric Cornwell |

|

Overhead Distribution

|

Ross Barrette Fernando Duarte Steven Dulin |

|

Underground Distribution

|

Joshua Perkel John Tripolitis Nigel Hampton Emily Majdi Alex Bologna |

|

Distribution Automation

|

Jason Anderson Krys Ford Mike Mazzantini Kim Thach |

|

Safety / Risk Management

|

Tom Short |

|

Asset Management and Analytics (Overhead and Underground Assets)

|

Bhavin Desai |

|

Distribution Reliability and Resiliency

|

Dexter Lewis |

General Inquiries

For general inquiries on EPRI research, please contact askepri@epri.com.